The 2014 MATE competition highlights the role that ROVs play in exploring and documenting shipwrecks, studying sinkholes, and conserving our national maritime heritage sites.

L Hetherington for | RoboticsTomorrow

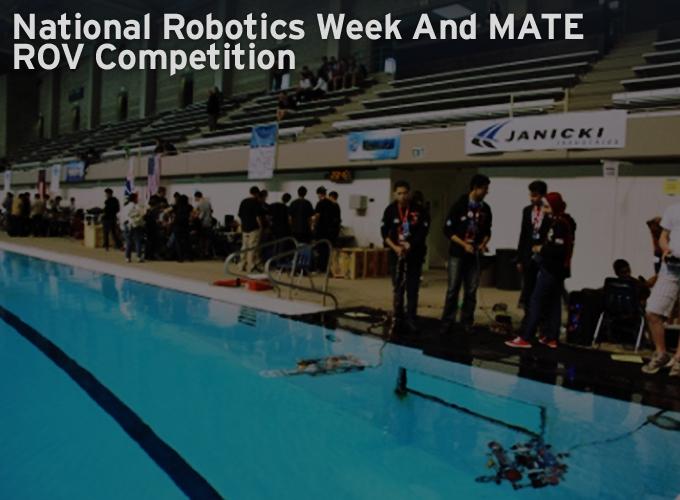

Last week was National Robotics Week. Along with other events, many regional teams competed to move forward in the 13th annual MATE underwater ROV competition:

A RUNDOWN FROM LAST YEARS EVENT:

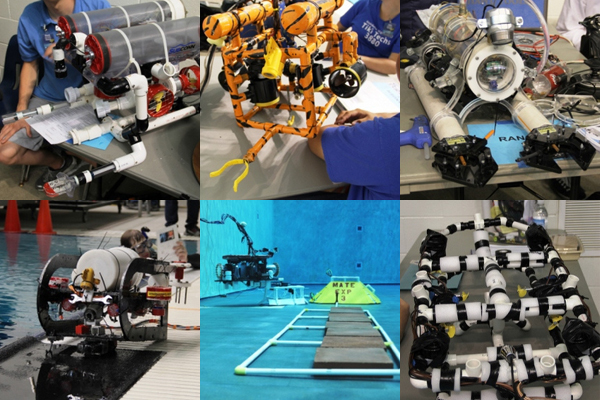

The 2014 MATE competition highlights the role that ROVs play in exploring and documenting shipwrecks, studying sinkholes, and conserving our national maritime heritage sites.

The competition is divided into 4 classes that vary depending on the vehicle specs & complexity of the mission tasks:

-

EXPLORER (advanced)(vehicle demonstration required)1

-

RANGER (intermediate)(participation in regionals required, some exceptions) 1

-

NAVIGATOR (beginner/intermediate) 2

-

SCOUT (beginner)2

1 these classes participate in the international competition

2 these classes participate in the regional contests

The 13th annual MATE international competition will take place June 26-28, 2014 at the Thunder Bay National Marine Sanctuary in Alpena, MI, USA... (full schedule of regional and international events)

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product