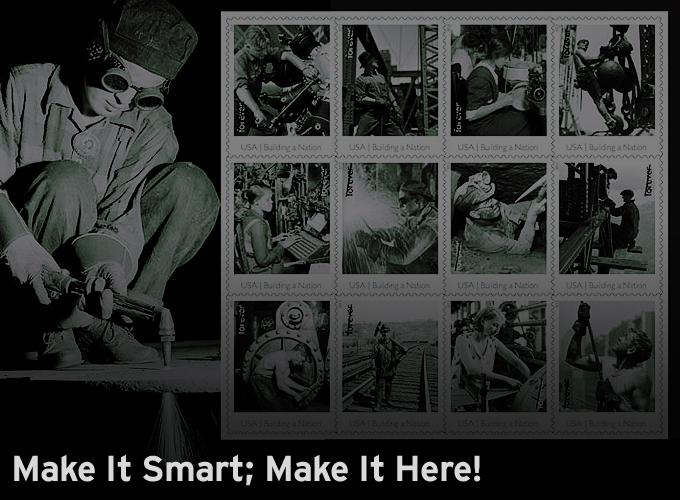

Make it smart and make it here! These are the rallying words heard around the world regarding keeping jobs in-country and manufacturing smarter, more efficiently, and less costly.

Frank Tobe, Editor and Publisher | The Robot Report

-

In the EU, the EU-funded SMErobotics program and the Fraunhofer Institute have been developing, and aiding in commercializing, robotic technologies to augment the skills and productivity of small and medium-sized shops and factories. Both the SMErobotics group and the Fraunhofer Institute have booths at the forthcoming AUTOMATICA 2014 trade fair and conference in Munich, June 3-6.

-

This year's focus at AUTOMATICA is Service Robots and Robotics. There is even a Service Robotics Competition (with only a few days left to apply): The Service Robotics Masters 2014 prize is a €5,000 grant for Service Robotics companies and another €5,000 grant for start-up companies.

-

A bigger competition is the $10 million EuRoC European Robotics Challenges competition -- an EU-funded grant program for innovations targeting three challenges to the EU manufacturing industry: reconfigurable interactive manufacturing cells; shop floor logistics and manipulation and plant servicing and inspection.

-

In the US, the government-funded Advanced Manufacturing Initiative has begun building a series of regional hubs to accelerate development of cutting-edge manufacturing technologies and products. Four such hubs have been launched this year -- patterned after the Fraunhofer centers in Germany.

- In addition to the US government, DARPA is investing in “...military-service-affiliated Manufacturing Demonstration Facilities that: (1) serve as repositories of focused manufacturing knowledge and infrastructure; (2) independently demonstrate designs, manufacturing processes, process models and manufactured products; and (3) curate and assess manufacturing models, qualification schema and material/processing properties data. These multi-user facilities are intended as a lasting, shared resource to provide the manufacturing community with greater access to the Open Manufacturing program and its research.”

One of the challenges of advanced manufacturing technologies is that it generates employment needs for specially-trained technicians with an understand of engineering, mechatronics and robotics as well as production methods. They are in short supply at present.

Community and tech colleges, as well as advanced tech universities, are attempting to meet those demands by offering certification and two- and four-year degrees in robotics and automation. Recently Worcester Polytechnic Institute (WPI) in the US and George Brown College in Canada have created fully online programs leading to their certificates or degrees in robotics (in WPI's case, one can now get a Master's in Robotics Engineering online); other colleges offer robotics technician certificates. A challenge to all these programs is that there is no standardization from one college to the next (whether online or not) and little coordination with local employers. Most cover the essentials but there are significant differences in curriculums.

Community and tech colleges, as well as advanced tech universities, are attempting to meet those demands by offering certification and two- and four-year degrees in robotics and automation. Recently Worcester Polytechnic Institute (WPI) in the US and George Brown College in Canada have created fully online programs leading to their certificates or degrees in robotics (in WPI's case, one can now get a Master's in Robotics Engineering online); other colleges offer robotics technician certificates. A challenge to all these programs is that there is no standardization from one college to the next (whether online or not) and little coordination with local employers. Most cover the essentials but there are significant differences in curriculums.

Certainly there is interest in robotics education. STEM programs stimulate interest in learning more about technology and engineering. Programs with a robotics focus like FIRST or VEX are working. Attendance at the FIRST Robotics Championship in St. Louis attests to the interest. will.i.am and Sheryl Crow performed and thousands of family, friends, team members and others (including the Deans of Admissions from Yale and MIT) attended this annual event. My two local FIRST teams, 1717 from Dos Pueblos High School in Santa Barbara, lost in the quarterfinals in St. Louis but won the Industrial Design Award; and Santa Ynez High School's team 5136, finished second but won the Rookie of the Year award.

Reprinted with permission from The Robot Report

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product