Operational excellence used to mean efficiency. Now, it means consistency. In a volatile manufacturing environment, the winners aren't those with the best machines or biggest budgets — they're the ones who can execute the same playbook flawlessly, every day, on every line.

How U.S. Manufacturing VPs Can Close the Execution Gap — The New Playbook for Operational Excellence

Saloni Banani, Marketing Manager | OrcaLean

Your strategy is solid. Your problem isn’t planning — it’s consistency.

Every manufacturing VP knows the feeling: the strategy looks brilliant in the boardroom, but three months later the results on the floor don’t reflect it. Production metrics lag behind targets, accountability fades, and meetings fill with explanations rather than progress.

This isn’t a leadership issue or a talent issue. It’s an execution gap — the silent distance between what leadership intends and what the plant actually delivers.

In U.S. factories today, the gap has widened. Global competition, labor variability, and fragmented systems have made consistency the hardest part of operational excellence. Yet the solution isn’t another initiative or meeting — it’s a new playbook that makes execution visible, measurable, and self-correcting.

That playbook is embodied in FactoryKPI, a real-time performance management platform that transforms manufacturing leadership from reactive to relentlessly consistent.

Why Execution Breaks Down — The Invisible Enemies of Consistency

Most plants aren’t suffering from lack of data — they’re drowning in it. MES logs, ERP reports, Excel trackers, and whiteboard updates compete for attention, creating a fog of metrics with no single version of truth.

The result:

- Leaders operate on lagging data. By the time KPIs show decline, the shift that caused it is long over.

- Teams work in silos. Quality, production, and maintenance each track their own dashboards, rarely converging on a shared view.

- Accountability becomes reactive. Meetings revolve around explaining yesterday’s problems, not preventing tomorrow’s.

- Middle managers get stuck in firefighting. Their time goes into updating spreadsheets instead of driving improvement.

When information, ownership, and follow-through are scattered, even the best strategies lose traction. Operational excellence demands one thing above all: alignment in motion.

That alignment doesn’t happen with more effort — it happens with systems designed to synchronize human behavior and data in real time.

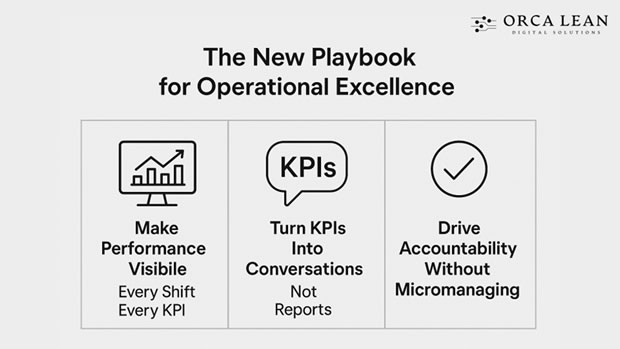

The New Playbook for Operational Excellence

U.S. manufacturing leaders need to move from managing by hindsight to leading by visibility. Here’s what the new playbook looks like:

Make Performance Visible — Every Shift, Every KPI

Visibility isn’t about fancy dashboards; it’s about creating shared truth.

FactoryKPI connects machine data, quality metrics, and shift reports into one unified SQDC dashboard — giving everyone from operators to executives a live window into plant performance.

When every team can see the same data in real time:

- Problems become facts, not opinions.

- Actions start faster.

- Leaders can coach, not chase.

This is digital visual management — the modern evolution of Lean’s “Gemba board” — accessible from screens on the shop floor to dashboards in the VP’s office.

Turn KPIs Into Conversations — Not Reports

Most KPI systems report history. FactoryKPI drives behavior.

It allows every deviation to trigger escalation — from frontline operators to supervisors and plant managers. Instead of waiting for end-of-week reviews, action loops close in hours.

This transforms leadership rhythm:

- Daily huddles focus on trend shifts, not spreadsheet updates.

- Tier meetings become faster and data-driven.

- Leaders see where engagement or ownership is slipping — and can intervene early.

Operational excellence thrives on micro-corrections made in real time, not post-mortems weeks later.

Drive Accountability Without Micromanaging

Accountability shouldn’t feel like surveillance. It should feel like alignment.

FactoryKPI builds “digital ownership” into every metric: every action, escalation, and acknowledgment is time-stamped and visible.

Supervisors don’t have to chase updates — the system shows who acted, when, and what the outcome was.

For VPs, this clarity changes the conversation from “Who dropped the ball?” to “Where do we need support?”

That subtle shift replaces blame culture with performance culture — a defining trait of world-class manufacturers.

How Great Manufacturing Leaders Use Data Differently?

Most factories collect data. Exceptional leaders turn it into behavior.

They Lead Through Visibility, Not Volume

Instead of more reports, they demand simpler, real-time signals that help them spot drift in safety, quality, delivery, or cost before it cascades. FactoryKPI provides exactly that — the SQDC lens that shows which part of the system needs attention right now.

They Use Data to Mentor, Not Monitor

Performance dashboards aren’t for policing; they’re for coaching.

When VPs use FactoryKPI, they don’t just track output — they can visualize patterns in shift performance, line bottlenecks, or absenteeism trends, enabling smarter conversations with plant managers.

They Build Systemic Trust in Numbers

Inconsistent data destroys culture faster than bad results.

FactoryKPI ensures one version of truth across departments. Operators, engineers, and executives work off the same metrics — ending debates about accuracy and starting discussions about improvement.

The Culture Shift: From Paper Lean to Digital Lean

Traditional Lean tools — visual boards, daily tier meetings, KPI trees — built discipline in a paper era. But as factories become more complex, distributed, and automated, paper can’t keep pace.

The next leap in Lean culture is Digital Daily Management.

FactoryKPI modernizes Lean principles for the smart factory era:

- Visual Management: Digital SQDC boards visible across all levels.

- Accountability Loops: Automatic escalation of missed targets.

- Tiered Communication: Connected daily huddles linking shifts, sites, and leadership.

- Continuous Learning: Trend intelligence highlights recurring gaps for Kaizen teams.

This isn’t Lean theory; it’s Lean at digital speed. By merging visibility and discipline, FactoryKPI turns daily management from a ritual into a performance engine.

FactoryKPI — Closing the Loop Between Strategy and Action

Every VP talks about “closing the loop.” FactoryKPI literally does it.

It bridges strategy, people, and execution through four key mechanisms:

- Unified Dashboards: Combine production, quality, and workforce metrics into a single view.

- Real-Time Escalation: When KPIs slip, alerts trigger automatically to the right level.

- Action Traceability: Every action is tracked to closure — with time, owner, and impact.

- Performance Cadence: Supports daily, weekly, and monthly review cycles — ensuring strategy execution stays on rhythm.

This structure keeps plants aligned even when leadership isn’t physically present. It creates a “digital nervous system” — a feedback loop that connects intent to outcome with precision.

FactoryKPI doesn’t just measure performance. It drives it.

Conclusion — Consistency Is the New Competitive Edge

Operational excellence used to mean efficiency. Now, it means consistency.

In a volatile manufacturing environment, the winners aren’t those with the best machines or biggest budgets — they’re the ones who can execute the same playbook flawlessly, every day, on every line.

That’s what FactoryKPI enables. It transforms disconnected teams into one aligned organism — where data flows, actions follow, and accountability feels natural.

Your strategy is already strong. The next leap is making it stick.

? See how FactoryKPI helps U.S. manufacturers close the execution gap — and turn operational excellence from a plan into a daily habit.

Saloni Banani is the Marketing Manager at OrcaLean, where she leads content and strategy focused on lean manufacturing, continuous improvement, and digital transformation in factories. She works closely with industrial leaders to bring real-world insights into manufacturing software adoption, data-driven performance, and shop floor excellence.

OrcaLean is a U.S.-focused industrial software company helping manufacturers digitize standard work, quality tracking, and problem solving. Its suite of lean manufacturing tools is built to support factory teams in real time—without the complexity of traditional enterprise systems. Learn more at: www.orcalean.com

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product