The case study presented herein illustrates the ease of utilizing consistent and reproducible 3D printed verification protocols as a means of ensuring the success of the restorative treatment plan.

Avi Cohen | Stratasys

Overview

Forward-thinking dental professionals, clinicians and laboratories are actively pursuing emerging digital dentistry technologies and quickly realizing the benefits. These advancements have yielded new, high-quality materials that are industrially pre-fabricated, tested and controlled, as well as a standardized process for the creation of exacting treatment solutions, both of which help the dental professional construct dental devices of higher quality and consistency.

Traditional ways of creating dental casts have multiple opportunities for discrepancies. Technique, material behavior and material properties can generate substandard results. And because techniques are individualized, noteworthy discrepancies can be seen from day to day, and person to person. Traditional materials exhibit expansions and shrinkages that are challenging to counterbalance and often difficult to control. These discrepancies prevent validating the cast within the oral cavity, potentially making the dental treatment stressful for both the clinician and the patient, since more chair time is necessary to address issues related to fit.

3D imaging software and 3D printed dental casts constitute the foundation of digital dentistry. With them, dental professionals are able to follow a controlled verification process that duplicates the topography of the intra-oral cavity precisely so that the actual seating of the device is fast and anxiety-free.

Finally, by employing digital dentistry technology, dental laboratories can accurately and rapidly produce a range of dental and orthodontic appliances, eliminate the bottleneck of manual modeling, and help the lab grow and stay ahead of the competition.

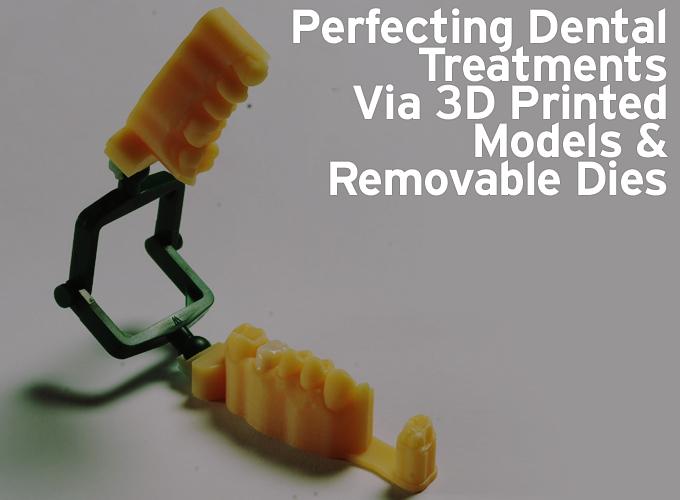

3D Printed Removable Dies

The removable die is an important component of the model system. Previously, dies were cut out individually to gain access to the prepared margin and accurately fit the restoration inter-proximately. This process was time consuming and often imprecise. The use of 3D printing helped address these issues but new challenges arose. While CAM software could segregate the dies from the main cast and print them separately, a large mass of dies were generally printed on one tray at the same time. These dies then needed to be cleaned, labeled and matched to each specific model. Furthermore, this method produced a slight horizontal shift or inconsistency in the die socket which frequently led to discrepancies in the final fit.

For these reasons, Stratasys set to work rethinking the printed model. A simple manipulation within the CAM software now allows the preparation to be duplicated and the removable die to be attached to the external cast, which can be used for verifying the margin. Additionally, now that the removable component has been eliminated within the un-sectioned solid cast, there is no potential for horizontal discrepancy shifts in fit.

Case Study

Clinical Considerations

A patient presented worn dentition, defective amalgam fillings and visible cracks in the molar regions (Figure 1). The patient, a bruxer, requested a conservative treatment rather than a full-mouth reconstruction to rebuild lost vertical dimension. A treatment plan was proposed to replace the defective amalgams with tooth-colored direct composite fillings, and place full- coverage zirconia Lava ™ Plus (3M ESPE) crowns where needed. Full-contour zirconia was chosen for the full crown material based on its strength, minimal reduction requirements and its ability to provide the desired tooth-colored appearance.

Figure 1: Pre-op photo.

Treatment began on the mandibular lower right quadrant. Teeth #28, 29 and 31 received new composite fillings. A composite core was placed in tooth #30, and the tooth was prepared for a full-contour zirconia crown (Figure 2). The gingiva was retracted to reveal the margin for the digital impression. Itero ® (Align Technologies) was used to scan the operative quadrant, the opposing arch, and finally, the patient’s bite. The resulting digital proposition produced a virtual cast for evaluation of complete capture of data and an accurate rendering.

Figure 2: Crown preparation of tooth #30.

Laboratory considerations

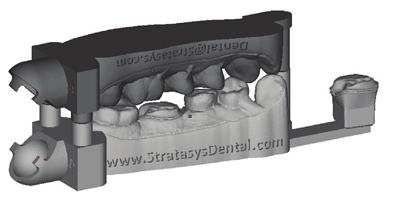

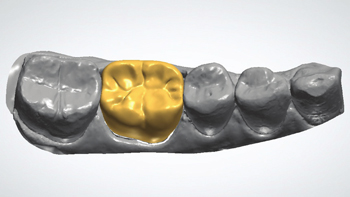

An open-formatted STL scan file from Itero was imported into the Dental Manager ™ (3Shape) CAD software. Dental Designer ™ (3Shape) software was used to annotate the location of the proposed crown for tooth #30, and both a sectioned cast and un- sectioned cast. Model Builder ™ software (3Shape) was used to reorient the scan data, set the plane of occlusion and identify the prepared tooth’s margins. Additionally, it proposed bases for both arches and a separated die was virtually extracted from the arch. STL files were generated for each cast part accompanied with an operative arch, opposing arch and an un-sectioned model with attached die (Figure 3). The crown was designed with 3Shape design software (Figure 4), then milled and sintered overnight according to the material manufacturer’s recommendations.

Figure 3: 3Shape Model Builder output.

Figure 4: Designed restoration.

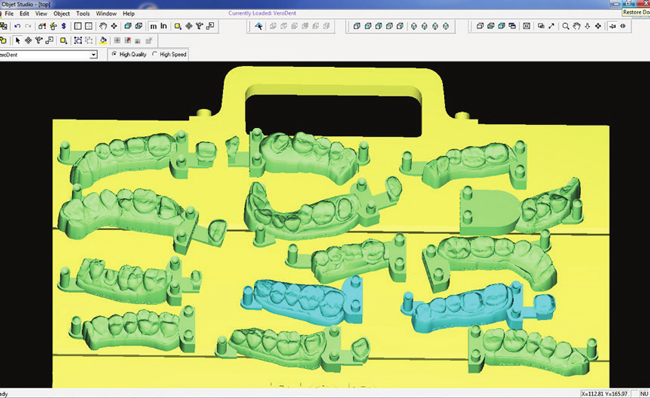

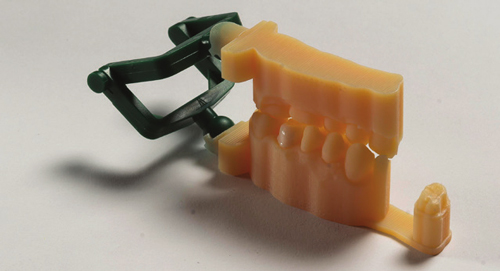

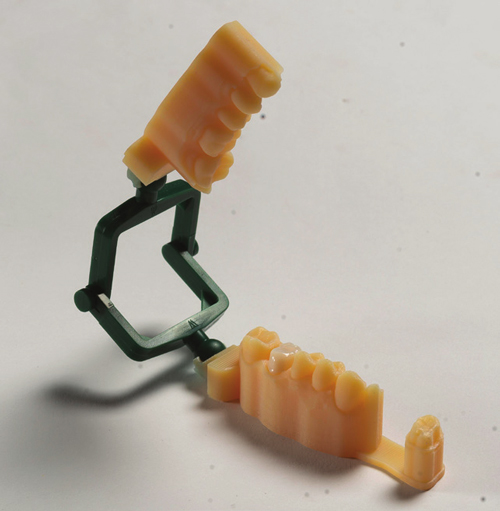

This innovative solution for a solid model – including a detached die and opposing arch – was generated, even though current Model Builder software does not support this solution automatically. The solid arch and detachable die were loaded into an industrial CAD software program (Figure 5). A small rectangular shape was created and used to bridge the space between the solid arch and the detachable die (Figure 6). The three individual shapes were combined into one file (Figure 7) and sent to an Objet ® Eden260V ™ 3D Printer (Stratasys ® ) along with other casts (Figure 8).

Figure 5: Solid arch and die.

Figure 6: Solid arch, die and bridge.

Figure 7: New solid arch.

Figure 8: Print job.

Restoration Seating

Once sintered, the crown’s margins were easily finished on the printed detachable die, and contacts were subsequently fitted to the solid model, thereby providing validation of the device while still in the lab. The crown was then stained, glazed and advanced to the clinician for seating. In the dental office, the Lava Plus zirconia crown was received from the dental laboratory and evaluated again on the model. The fit of the crown on the detached die was perfect, with no rock or rotation, and the margins were undetectable. Interproximal contacts were validated on the solid model as broad and firm. Minimal adjustment was required and the crown was bonded with Scotchbond ™ Universal with RelyX ™ Ultimate Adhesive Resin Cement (3M ESPE) (Figure 9). This verification protocol was utilized systematically in the laboratory, and then subsequently in the dental office to produce a superior, verified and consistent dental treatment.

Figure 9: Restoration placed.

Conclusion

As shown in this case study, the innovative new cast CAD/CAM method ensures accuracy and precision by confirming the fit of the crown in the patient’s mouth, before it leaves the dental lab. All horizontal inconsistencies, which previously led to chair-side adjustments, have been alleviated by using a new verification protocol with the detached die for margin finishing, and the un- sectioned solid model for contacts.

Digital dentistry is rapidly becoming the norm within the profession, and serves as a valuable business tool for dental laboratories by cutting production times, lowering labor costs, and increasing efficiency, accuracy and profitability. What’s more, digital dentistry offers dentists the use of consistent, state-of-the-art dental devices, and their patients a superior healthcare experience.

Figure 10: Printed dental model with a non-removable die.

Figure 11: Printed dental model using VeroDentPlus ™ material.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product