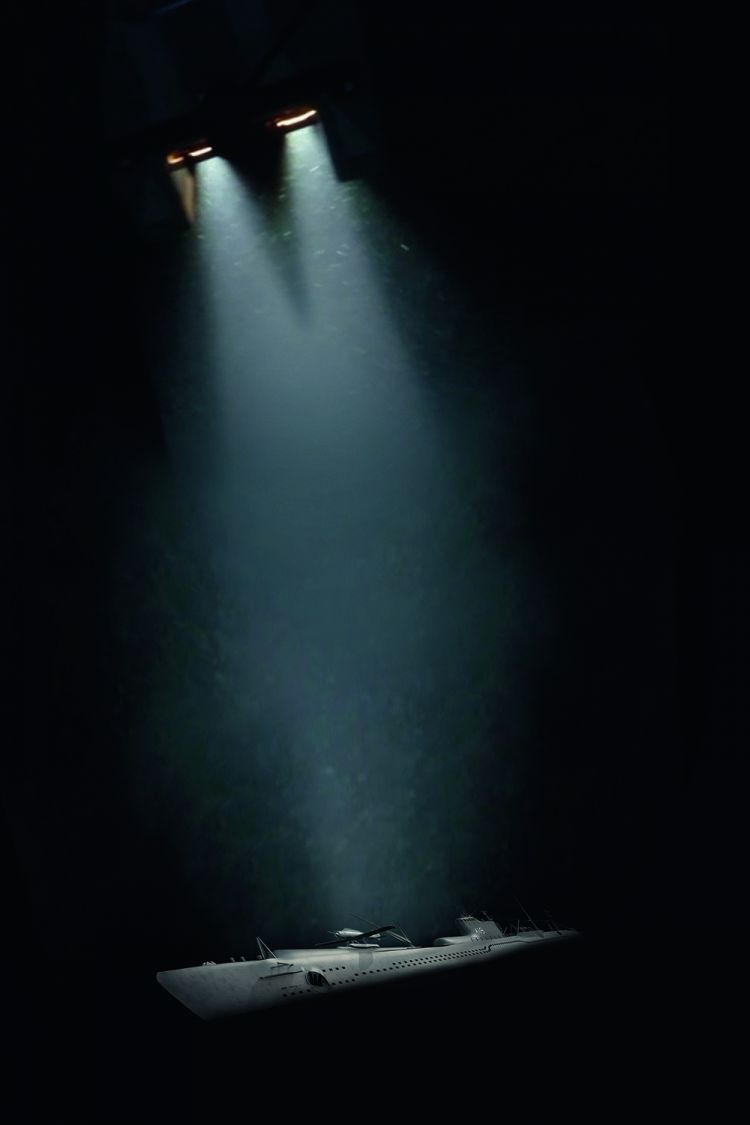

The largest submarine of WWII has been sitting on the bottom of the ocean off the Japanese coast for 70 years. Researchers finally found the lost wreck with the aid of an underwater robot – and Swiss drive technology.

In Search of a Lost Veteran

Stefan Roschi | Maxon

The old steel giant rests at a depth of 190 meters, dilapidated and overgrown. Yet the researchers quickly realized that this wreck is the Japanese submarine I-402: the largest submarine built in WWII, 120 meters long, carrying three airplanes that were able to take off via a pair of launching rails. After Japan’s capitulation, the US military scuttled the vessel at an unknown location. With the aid of a state-of-the-art dive robot from Canada, scientists discovered the wreck in summer 2015.

LED lamps illuminate wreck parts

The robot is a ROV: a remotely operated vehicle that moves underwater. It was built by Seamor Marine, a manufacturer of compact, easy-to-navigate ROVs that can be fitted with various accessories such as sonar, depth gauge, and scanner. A high-resolution camera and powerful LED lights are among the standard equipment of the ROV. These lights played a central role in the identification of the Japanese wreck, as they illuminated its specific features. Controlled via a cable, the ROVs are able to reach depths of up to 600 meters.

The operator pilots the machine with a panel at surface level from a boat, dock or dry land, using a real-time video feed and onboard compass to navigate underwater.

“Underwater archaeology is only one of many applications for our vehicles,” says Elaine Parker, who is in charge of marketing at Seamor. The ROVs are commonly used to inspect water tanks, pipelines, or the hulls of ships and boats. “We are also seeing increased applications in tourism, for example at the Shanghai Aquarium, where one of our ROVs is used in an exhibition.”

Suitable for experts and beginners

Seamor set itself the goal of developing remote-controlled underwater vehicles that are reliable and easy to use. Many customers are not specialists in the field, therefore operation has been made intuitive and easy to learn. “Our ROVs reach places that are inaccessible to humans, or too dangerous,” says Robin Li, Seamor Marine Company President.

The vehicles also have to be lightweight enough to be handled by one or two people. The difficulty when developing this kind of ROV is to achieve a compact system that simultaneously has powerful drives. This is why Seamor uses maxon products. The underwater drives of the vehicle consist of a motor-and-gearhead combination: a DC motor (RE 40) and a planetary gearhead (GP 32) with ceramic components. Seamor also uses several maxon drives for the underwater gripper and the camera angle adjustment. The company chose the Swiss drive specialist because, as Seamor Lead Engineer, Dr. Chris Parker, said, “maxon is the leader in high-quality DC motors and is able to deliver a product that fulfills our specific requirements.” The motors of a Seamor ROV need to deliver high power while taking up little space. Low noise is also important. Last but not least, tight tolerances in the drives are critical for preventing vibration that might cause seals to fail underwater.

Russian bomber plane in Finnish lake

Seamor ROVs are seeing widespread use these days. The company sells up to 50 units annually. Therefore, it comes as no surprise that, once again, a Seamor vehicle recently caused a stir. On the bottom of a lake in Finland, it illuminated the silhouette of a Soviet aircraft crashed in 1941.The ROVs can provide images from a depth of up to 600 meters. The vehicles are controlled via a console – the screen helps with orientation.

In the final days of WWII, Japan developed a novel submarine that was larger than all types known at the time. The objective was to reate a submarine class capable of reaching any point on the globe and returning to Japan. It also needed to offer space for several planes that could be launched from the deck. In the end, only three of these submarines were completed. They were 122 meters long, with a weight of 6,600 tons. The hull offered space for three specially designed airplanes. Japan was planning to use this super weapon to attack cities on the East Coast of the US. However, these plans never became reality. The three submarines were captured by US forces. The Americans were quite surprised and thoroughly analyzed the technology. I-402 was scuttled right where it was; the two other exemplars were taken to Hawaii, where the US military destroyed them later to prevent the Soviets from inspecting the submarines as well. The remote-controlled underwater vehicle from Seamor supports archaeologists in the search for the missing submarine I-402.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

Other Articles

How Parvalux Is Helping to Develop the Next Generation of Conveyor Systems

Robots speeding up material handling

The rise of modular robots and the importance of drive train design

More about maxon group

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product