By coupling its cloud and open autonomy platforms to disrupt agriculture, Northstar Robotics is on track to solve farm labor shortages and reduce farm input costs.

Swift Navigation Case Study: Northstar Robotics

Swift Navigation Case Study: Northstar Robotics

Contributed by | Swift Navigation

Founded in 2016, Northstar Robotics is an agricultural technology company focused on delivering autonomous solutions to benefit farmers. Upon inception, its founders looked to their home province of Manitoba, Canada and identified the need to address both the agricultural labor shortage problem and to lower farm input costs. Using advanced technologies, Northstar Robotics is working to attract talent to—and investment in—Manitoba and to benefit farmers across North America.

Challenge

There are many factors at play for the labor shortage facing today’s farmers— from an aging workforce, traditional laborers moving to higher paying jobs, lack of local labor to overarching immigration policies—but the need for qualified labor remains. Distinct from historical shifts to robotics and technology in other industries, many farmers would prefer to hire human labor to tend their crops but turn to technology as that becomes a less reliable option.

The cost of this shift can be cumbersome, as simply replacing equipment with the latest technology is not a financially feasible solution for most farmers. Farmers have invested a lot of money in their equipment and it doesn’t make financial, or practical, sense to replace tractors and combines that are in good working condition.

Solution

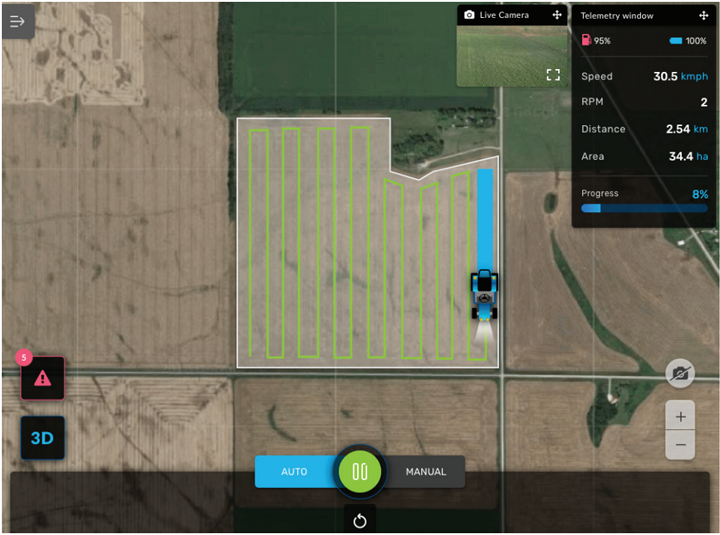

Through its open hardware and software platform, Northstar Robotics is working with farmers to turn existing farm equipment into customized, autonomous solutions for their fields. Its retrofit kit works well with most equipment since many models of tractors use the same steering, acceleration and control systems. Using its industry insight and technological know-how, Northstar Robotics is also building new robotic applications to transform farming and set the standard for what modern agricultural equipment should be. Northstar Robotics’ intelligent control system connected to its cloud robotics platform allows farmers to dictate to equipment its task—feed it, weed it, seed it, harvest it—all from the OpenSteer app on their phone.

To deliver the precision required to complete such tasks, Northstar Robotics utilizes GPS as its main sensor and requires high-precision technology to ensure accuracy for its farming customers. Initially Northstar Robotics tested a singleband receiver as part of its solution but realized that a multi-band receiver was needed to deliver both accuracy and faster start times. It also required a complete solution that could get GNSS corrections over a network. Northstar Robotics turned to Piksi® Multi—the multi-band, multi-constellation GNSS receiver from Swift Navigation.

Results

Piksi Multi delivers centimeter-level accuracy and is able to achieve an RTK fix within seconds. In addition to its precision and affordable price, Piksi Multi is an ideal resource for agricultural autonomy localization with its ability to provide location information in a field without lane markings or other distinct features, along with repeatability and stationary heading.

Using Piksi Multi, Northstar Robotics is able to deliver a three-pronged approach to achieve its vision. It works with OEMs interested in creating the next generation of smart precision agriculture machines, it makes Autonomy Kits allowing early adopters to add autonomous capabilities to their existing equipment and it offers custom retrofit services to take a farmer’s existing equipment to make it fully autonomous.

By coupling its cloud and open autonomy platforms to disrupt agriculture, Northstar Robotics is on track to solve farm labor shortages and reduce farm input costs.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product