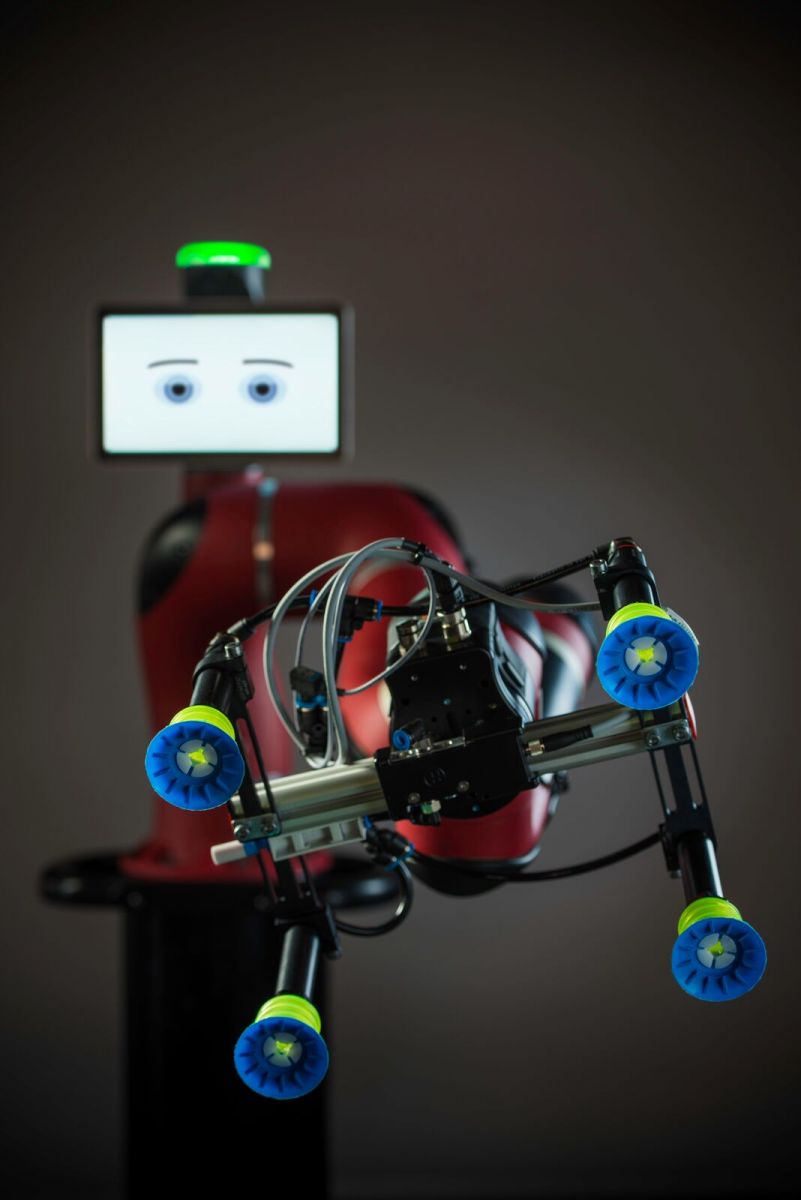

East Building, Level 3, #134765 - Rethink Robotics will be exhibiting its Sawyer cobot alongside two recent product developments at IMTS 2018: The ClickSmart™ platform and its family of gripper kits and the industry-leading software, Intera 5 with Intera Insights.

Contributed by | Rethink Robotics

Tell us about your company.

Rethink Robotics' collaborative robots transform the way work gets done in manufacturing and distribution operations. Powered by the Intera software platform, its Sawyer™ and Baxter® cobots can be trained and on the job in a matter of hours, are designed to work safely alongside people, and are highly reliable, adaptable and easy-to-use. Deployed globally, Rethink Robotics' cobots provide a cost-effective industrial automation solution to several of the toughest issues manufacturers face today, including a shortage of skilled labor, sustainable levels of quality and efficiency and an opportunity to automate a wide range of tasks on the factory floor. Based in Boston, the Rethink product suite is available in Asia, Europe and North America. The company is funded by Bezos Expeditions, CRV, Highland Capital Partners, Sigma Partners, DFJ, GE Ventures and Goldman Sachs.

Your company will be exhibiting at IMTS, what is it that makes this an important event for your company?

Robotics and automation are no longer restricted to certain areas of manufacturing – with the evolution of cobot technology, manufacturers can automate more tasks than ever before. As manufacturers begin to realize the benefits of automation in terms of quality, ROI and efficiency, demand for cobots will continue to grow. We’re here to help manufacturers see the benefits cobots provide, and ensure they deploy Sawyer on the tasks that will make an immediate and profound impact on factory operations.

Highlight 2 or 3 products you will be showcasing at the event?

Rethink Robotics will be exhibiting its Sawyer cobot alongside two recent product developments at IMTS 2018: The ClickSmart™ platform and its family of gripper kits and the industry-leading software, Intera 5 with Intera Insights. Both designed with users in mind, Rethink aims to provide manufacturers with the high-performance automation they need while maintaining adaptability, safety and affordability.

Sawyer is the fastest to deploy collaborative robot on the market and can be up and running in a matter of hours, without the need for a programming or robotics engineer.

With a small footprint and built-in force sensing capabilities, Sawyer operates safely next to its human counterparts without any gating or fencing required.

IMTS has many educational sessions & Demo’s, is your company involved in any of them this year?

Attendees will be able to get demos and train Sawyer themselves throughout the show in our booth when they visit.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions you plan on attending?

Manufacturing technology is evolving so quickly we are looking forward to seeing the brand new technologies that have evolved since IMTS in 2016

When you book a booth for a tradeshow like this what are your expectations and what does your company hope to accomplish at the event?

We’ll be demonstrating the capabilities of automation and the benefits cobots can bring to manufacturing. Prior to cobots, manufacturing robots were large, expensive equipment that was kept behind cages, programmed by highly paid specialists, and purchased for a single purpose. Cobots change all that – they’re safe to be around, require a much smaller footprint, are easy to program and are inexpensive enough to provide a rapid return on investment. At IMTS, we’ll connect with attendees from various industries to showcase how automation can improve their manufacturing and production operations. We also expect to learn about the latest trends in the industry and gain a better understanding of our customers’ needs.

A tradeshow of this magnitude is extremely busy and stressful for the staff of exhibiting companies. Any fun things or places your team can suggest in Chicago to help unwind?

There’s always something fun to do in Chicago. If you haven’t been before, take a walk along Lake Michigan to Navy Pier, and Millennium Park has the famous Cloud Gate. Friends Sushi on Rush Street is delicious if you get tired of deep dish pizza. If you dig the blues, check out Blue Chicago, a great live music venue with Goose Island on tap and great music every night of the week. Of course, being from Boston, we’re Red Sox fans, but Wrigley Field is quite an experience (almost on par with Fenway).

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product