Booth #N5853 - KEBA offers KeMotion which is a complete solution for robot and machine automation. PLC, motion, robotics, drive technology, safety technology and HMI are all combined in a compact system.

Contributed by | KEBA Corp.

Tell us about your company.

Founded in Linz in 1968, KEBA today is an internationally active company that creates its success from technological innovations, the highest quality requirements, and the dynamism and enthusiasm of its employees. KEBA works on new developments and industry solutions with the objective of creating sustainable competitive advantages for its customers.

For 50 years, KEBA has been developing and producing according to the motto “Automation by Innovation” by creating innovative automation solutions for a wide variety of industries. KEBA customers enjoy the best care. The range spans from initial consultation through system design to installation and series support.

Your company will be exhibiting at PACK EXPO, what is it that makes this an important event for your company?

This year’s PACK EXPO allows us to understanding the world of our customers and their challenges. Today, we are one of the leading automation experts in many industries because we know our customers' processes in detail.

Highlight 2 or 3 products you will be showcasing at the event.

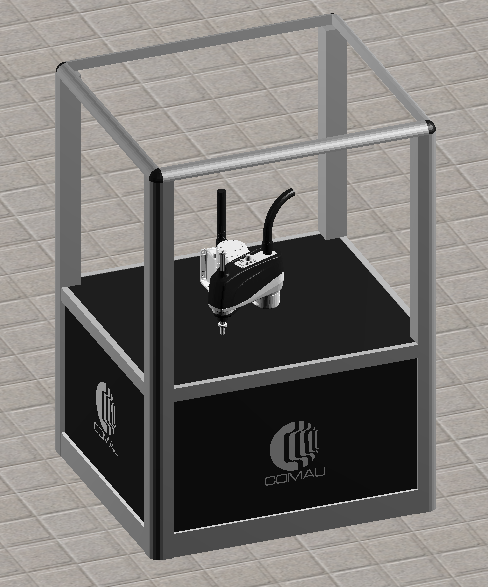

COMAU & KEBA – the perfect combination.

KEBA offers KeMotion which is a complete solution for robot and machine automation. PLC, motion, robotics, drive technology, safety technology and HMI are all combined in a compact system.

This is the ideal basis for implementing all automation tasks on a single common hardware and software platform. The Comau robotic demo cell features a Comau Rebel-S robot, a 4-axis SCARA robot that is available in 5 different models with a payload of 6kg and 3 different reaches.

These robots can be mounted in a variety of positions and they utilize spacers - a simple, yet innovative solution that extends the robot’s reach. At this event, the Rebel-S will be demonstrating a pick & place operation, showing its compactness and flexibility.

Benefit from the perfect combination between COMAU and KEBA and enjoy all the advantages!

The KeTop T150 has a capacitive touchscreen that can be operated as a true multi-touch and thereby scores with its intuitive usability, maximum ergonomics and best user experience.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see?

We are interested to visit the Future Innovators Robotics Showcase. Prompting robotics in the next generation is a key to the continued growth of automation and robotics in all industries.

The factory floor is undertaking rapid advancements, be it automation, robotics, machine vision or data. The process of packaging is a huge part for many manufacturers, give us an idea on how your company and product is being utilized now in the smart factory.

With the increasing need for flexibility and individualization in industry, the complexity in production is continuously increasing. KEBA provides innovative automation solutions for Industry 4.0 for digitizing machines and thus production.

Here we focus on:

- the control of machines and manufacturing equipment

- the operation of the machines and processes

- the communication and data processing between the levels of the value chain

- the development environment of future, digital I4.0 solutions and

- low-level cloud applications

KEBA solutions help to make these new I4.0 technologies easy to use.

Give us your thoughts on what the future holds for manufacturers and packaging.

Manufacturers of packaging machines must constantly face the challenge of increasing machine productivity and thereby reducing the manufacturing costs for packaging. This requires innovative, flexible and fully-automated machines in which all benefits of modern automation solutions such as movement control, robotics, integrated safety, machine operation and maximum networking are implemented.

The KEBA portfolio in the area of packaging ranges from turnkey packaging and safety solutions to innovative mobile and stationary operating solutions and an open control platform, depending on the requirements of the customer.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product