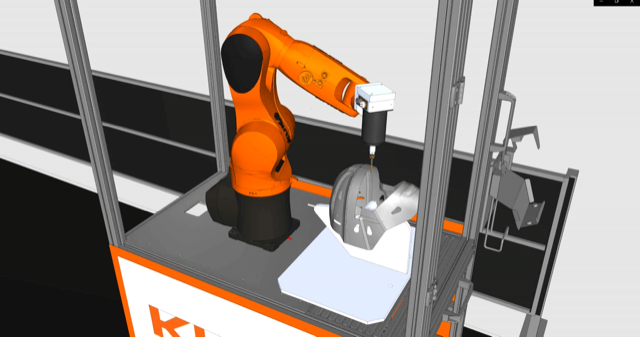

Booth #8520 - In the OCTOPUZ booth, visitors will be able to see a Motoman MH5L performing a weld tracing operation on an automotive rim as well as a KUKA KR6 R700 deburring a helmet both programmed and simulated within OCTOPUZ.

Contributed by | Octopuz

Tell us about your company.

OCTOPUZ is an offline robotic programming and simulation software that enables users of all experience levels to program and generate robot code in a simple and easy way. With OCTOPUZ, users can program all their robots, regardless of brand and application, within one platform. Whether you are importing CAM from your favorite CAM software or creating paths within the OCTOPUZ solution, OCTOPUZ offers a powerful, flexible and customizable environment.

Programming your Industrial Robots to leverage your design efforts, regardless if Welding, Milling, Trimming or Deburring should not be a difficult process. Let us take care of the hard part, allowing you to spend more time manufacturing and less time programming.

Your company will be exhibiting at AUTOMATE, what is it that makes this an important event for your company?

Automate is an important event for us at it creates a hub for a wide range of automation technologies. Not only does this event attract visitors that are a great fit for our product but it also exposes us to the variety of companies offering different technologies within the automation space.

What makes your booth a must visit for AUTOMATE Attendees?

Late last year, OCTOPUZ demonstrated the BETA version of OCTOPUZ 2.1 at FABTECH. Now, with OCTOPUZ 2.1 in the market, visitors at Automate will be able to see and use the final product currently in the hands of our customers and partners. Those who have seen and used the new version have expressed particular interest and amazement at the PathFinder suite of features that were released in V2.1. Users are now able to import or generate their toolpath to then be automatically analyzed for errors and automatically solved with a click of a button using OCTOPUZ Intelligence. This suite of tools further simplifies the programming process making it even easier to program complex paths from the comfort of a computer.

In the OCTOPUZ booth, visitors will be able to see a Motoman MH5L performing a weld tracing operation on an automotive rim as well as a KUKA KR6 R700 deburring a helmet both programmed and simulated within OCTOPUZ.

AUTOMATE has many educational sessions, forums & Demo’s, is your company involved in any of them this year?

The OCTOPUZ team has been preparing some fantastic demos that we will be hosted in our booth for visitors. These demonstrations have been strategically designed to show a variety of complexities and cell configurations covering a variety of applications from welding, milling, deburring, trimming, material handling and more. Our focus during these demonstrations will be to show the enhanced simplicity of programming with OCTOPUZ leveraging the PathFinder suite of tools included in V2.1 as well as our de-risking / prototyping simulation capabilities. With the latest release, users can import or generate a path within OCTOPUZ, use the PathAnalyzer tool to determine if there are any errors within the program, and then solve any errors with a click of a button using PathSolver.

We are very excited to show off the latest features and encourage attendees to stop by our booth to see these features for their particular application and robot brand.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

As we mentioned above, Automate is a fantastic show for us as it collects the latest technologies within the automation world under one roof. Our team is most excited to walk through our partner booths to see what the latest technologies they are offering as well as new / emerging companies with innovative technologies.

The factory floor is undertaking rapid advancements, be it automation, robotics, machine vision or data. Automation Technology is a huge part for many manufacturers, give us an idea on how your company and product is being utilized now in the smart factory.

Offline Robotic Programing Solutions like OCTOPUZ enable manufacturers to add another layer of automation to their smart factories.

By incorporating OCTOPUZ within the automation portfolio, manufacturers are able to increase their robots productivity, simplify the programming process, and generate error free programs without taking the robot out of production. This drastically increases the ROI they see from their robotic cell, allows them to be able to take on more jobs and enter new markets!

The terms digital twin and prototyping are becoming big buzz words in the industry - the idea of designing, visualizing and proving a concept prior to heavily investing in the project. These are projects that OCTOPUZ has been increasingly involved in as users can create a quick simulation for proof of concept and then feasibility studies can be performed directly within the platform.

Give us your thoughts on what the future holds for manufacturers and automation technology.

For many manufacturing facilities the future can be scary. Many fear that they will not be able to keep up with the competition or that investing in robotics and automation may not yield the returns they are hoping for. Our goal is to mitigate those fears by providing a solution that allows them to feel comfortable programming their robotic systems free of errors by using a platform that is not only easy to use but has the ability to guide the user through the path analyzing and error solving process.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product