Booth #7732 - Dorner will be exhibiting our platforms aimed at automation and robotic applications. Dorner’s 2200 Precision Move Pallet conveyor is designed to provide accurate positioning and routing of parts for assembly, robotic and inspection applications.

Contributed by | Dorner Conveyors

Tell us about your company.

At Dorner our mission is to Transform Conveyor Automation by providing cutting edge solutions with best-in-class support. It’s that commitment and history of proven excellence that has made the Dorner Brand a recognized leader in conveyor systems for over 50 years. With our complete line of customizable stainless steel and aluminum conveyor automation systems, Dorner can provide solutions for almost any conveyor need.

Dorner’s conveyors are designed to move product to the exact location, at the exact time and in the exact position it needs to be for the next phase of the production line. With benefits such as industry best product transfers and in-house belting capabilities, Dorner is leading the market in precision conveyance. This extremely accurate product control allows Dorner conveyors to easily integrate with robots, workers and equipment.

Your company will be exhibiting at AUTOMATE, what is it that makes this an important event for your company?

Automate is the premiere Automation trade show in North America and it is a great opportunity for us to interact with other companies and customers in the industry.

What makes your booth a must visit for AUTOMATE Attendees?

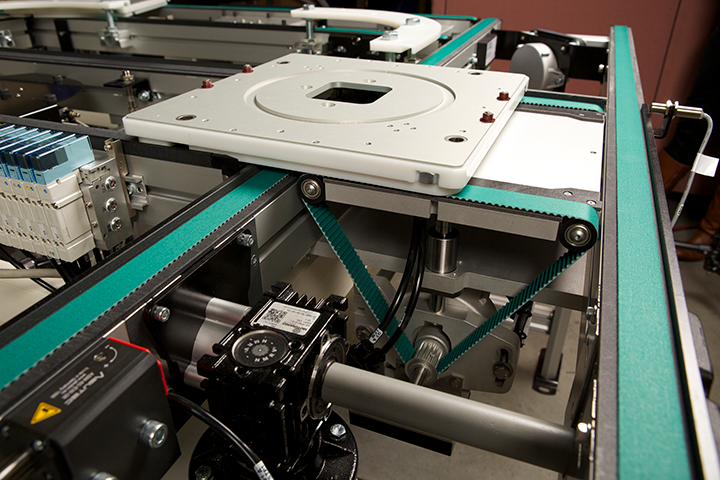

Dorner will be exhibiting our platforms aimed at automation and robotic applications. Dorner’s 2200 Precision Move Pallet conveyor is designed to provide accurate positioning and routing of parts for assembly, robotic and inspection applications. The 2200 Series Precision Move Pallet System is now available with new features including heavy load corners, tight turn corners, low-profile lift and locates, elevators and more.

Attendees can watch the dual belt 2200 Precision Move Pallet System operate while integrated with a Universal Robot (UR) robot to move and orientate products using an elevator, passing over a lift and locate station and navigating through a 180° heavy load corner. Additionally, Dorner and its 2200 Series conveyor are now a certified UR+ Solution partner that simplify robot and conveyor integration for a wide variety of automated applications.

We will also be displaying our SmartFlex® Pallet System conveyor, which is engineered for product routing, control, and inspection in small- to medium-size assembly automation applications. SmartFlex® components, sold as completed assemblies or as kits, offer users layout flexibility and the ability to implement conveyor system design changes easily. Components include merge and divert modules, lift and locate stations, cushioned pallet stops and a unique pin tracking system to guide pallets through 90° turns; all of which attach directly to the conveyor frame, without the need for modifications. Customers can purchase SmartFlex® mechanical components separately or as part of a complete electrical solution.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

We always look forward to seeing what new technologies and innovations are being exhibited at Automate. There are also a variety of informational sessions that provide us with valuable insight on industry topics.

The factory floor is undertaking rapid advancements, be it automation, robotics, machine vision or data. Automation Technology is a huge part for many manufacturers, give us an idea on how your company and product is being utilized now in the smart factory.

Often times the significance of the conveyor in the factory can be underestimated. A manufacturing line can only go as fast as your conveyor. The entire line is limited by the slowest machine on the line. With our conveyors, we put a big focus on precision and product orientation so when it gets to that next piece of equipment, it’s ready and it won’t be the bottleneck. So often, the simplicity of conveyors is overlooked

Give us your thoughts on what the future holds for manufacturers and automation technology.

Automation really demands efficiency. Integrating robots with precision conveyor systems is one way to enhance the productivity of a processing line. Robotic applications often require a product to be in an exact spot on the conveyor at the right time. But to do that successfully requires a conveyor system that’s efficient, reliable and engineered to work in conjunction with robotics. Conveyor design is certainly being affected by the continuing trend of flexible assembly lines. When customer demands change and product cycles end, assembly lines need to be flexible to accommodate different applications

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product