Our concentration is to develop a surgical robot to go where it is needed the most, bringing the best competencies to where the injury happened. After all, if we can pilot a drone we should be able to operate a surgical robot.

Bringing Robotic Surgery to Places Where Others Don't Want to Go

Bringing Robotic Surgery to Places Where Others Don't Want to Go

Gianluca DeNovi | XSurgical

Tell us why you brought XSurgical to Cambridge, MA.

Cambridge is in fact the equivalent of the Silicon Valley for the medical field. All of the big players in the different medical domains are interested in locating in this area for a number of reasons. First, the main universities are here and they are connected with the most advanced teaching hospitals in the world. Most of the leading research and innovation is focused in the Boston/Cambridge area. The nine years I have spent here have shown me that I could never find a better place to recruit world class scientists and engineers. When it was time to choose the new home for XSurgical I had no doubt that Cambridge/Boston is the best place to develop the business and continue the research, as well as for new opportunities.

What do you see as the need for robotic surgery in general?

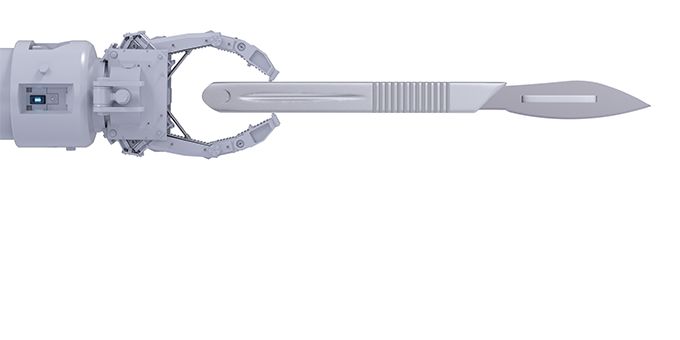

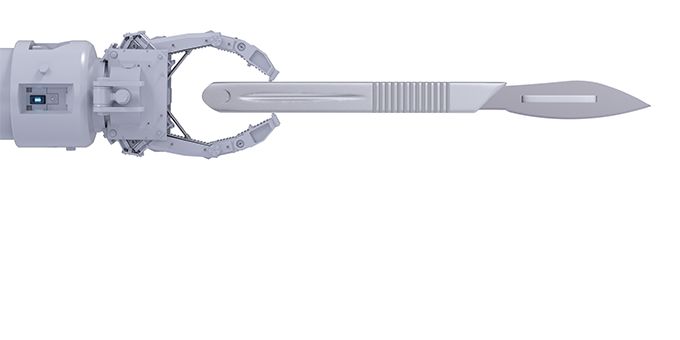

Robotic surgery is an up and coming field and one which will increase in importance over time. To date, it seems there has been a lot of time in laboratories and not as much in the hospitals. At this stage there are too many prototypes and just a few real products. The few products available today fight for the same slice of market and offer essentially the same kind of procedures in the most economic way. At XSurgical we are pursuing a different strategy, seeking to do what the others haven’t and bringing the robotic surgery to places where the others don’t want to go. Using robots in surgery is valuable; it allows surgeons to do things that were hardly possible with bare hands. Also, its demonstrated value over the last decade has been that we have learned that there are specific places where a robot is really necessary and can make a difference. One such example is on the battlefield, where there may not be any surgeons close at hand to undertake emergency surgery. Our concentration is to develop a surgical robot to go where it is needed the most, bringing the best competencies to where the injury happened. After all, if we can pilot a drone we should be able to operate a surgical robot. And, if we build a robot which is “smart enough,” the robot will learn from us how to accomplish certain things autonomously or at least with remote supervision.

What are the specific applications you see for this robot (i.e., battlefield, first responders)

The first responders in areas affected by disasters or wars are absolutely critical, enabling best in class surgeons to operate remotely. But there is more. Artificial Intelligence (AI) is an important piece of the puzzle and we are betting heavily on its value.. The integration of AI in a surgical robot is not an easy task from a technological standpoint nor from a certification point of view, but the benefits are unmistakable. And, in many other branches of the medical field (and other fields as well) this is already happening and has been for a number of years. We are working today to develop the technology for tomorrow. As an example, there’s increasing talk about manned spacecraft going to Mars. As we all know, it’s about more than propulsion systems and habitat,; it is equally important for us to develop the medical technologies needed to assure the well-being of people on such a long and perilous journey. Our name shows exactly what we are aiming for:“X” in the name “XSurgical” refers to “what hasn’t been done yet.” .

Is there a date you anticipate the next iteration will be released?

We don’t have a specific release date yet. The development depends heavily on the investments we will receive; probably sometime in the next three to five years the third iteration should be ready to bring to market. It’s important to note that we have two iterations of the surgical robot already, and future iterations will draw heavily from what we have already accomplished in development. That being said, we do plan to be quite aggressive in the development and have aligned a series of milestones that will bring us to the final release of the Gamma version.

What types of surgery would the gamma be able to perform?

The biggest difference with the Gamma iteration is that we will be able to go beyond the minimally invasive set of procedures (similar to what other commercial robots offer) to an advanced set of open surgical procedures. These could include, but not be limited to, hemorrhage control, cranio-facial traumas and over time a support for all the type of injuries that lead to complications when not properly treated in the first few hours.

We understand that the military has expressed interest in the robots. Do you see this as a strong market?

We don’t have a formal statement of interest from the Department of Defense per se, but we do have interest from key medical personnel. The Department of Defense is investing significant resources in seeking to develop novel technologies to support soldiers and civilians in very critical environments and situations. We share this vision; and it’s natural for some of their physicians to show interest in the concept of robotic surgery. I spent much of the last decade working on military funded projects and I would be honored to keep serving this country developing novel medical technologies. We consider the market opportunity offered by the critical environments extremely interesting but see an even bigger opportunity in the subsequent applications that will result from this..

What are some other markets you are looking at?

We are not giving up on the purely civilian market (hospitals) but presently we are trying to build the base technology for the applications of tomorrow, which include the ones that we can see (such as space missions) and also for the others that we can’t yet see. If we can bring the robotic surgery virtually everywhere, then I am sure that new opportunities and markets will be revealed.

We understand you are looking at seeking investors and potentially an IPO. Can you tell us a little about that?

At this moment we are seeking investors to support our initial work on the Gamma version. This will be a step that will bring us toward an IPO which we hope to have in a pre-revenue stage in a two year time frame. We believe that there are a number of reasons to offer investors the opportunity to bet more on us. We are confident that the IPO in two years will be supported by the results that we will deliver in the development phase. We develop technologies to support life and, for life, we mean everyone. It is fair to offer anyone the ability to participate in our project.

About Dr. Gianluca De NoviDr. Gianluca De Novi is the CEO of XSurgical.. He received his Masters degree in Electronics Engineering and his Ph.D. in Robotics and Control Systems from the University of Bologna. After spending a year as a visiting researcher at the Bio-Robotics Laboratory of Harvard School of Engineering and Applied Sciences, he completed his postdoctoral fellowship in medical simulation at the Department of Imaging of the Massachusetts General Hospital and Harvard Medical School in Boston. He is an instructor at the Harvard Medical School and a former Visiting Professor at the University Campus Bio-Medico of Rome. He is also Director of the Medical Device and Simulation Laboratory at Massachusetts General Hospital.

About Dr. Gianluca De NoviDr. Gianluca De Novi is the CEO of XSurgical.. He received his Masters degree in Electronics Engineering and his Ph.D. in Robotics and Control Systems from the University of Bologna. After spending a year as a visiting researcher at the Bio-Robotics Laboratory of Harvard School of Engineering and Applied Sciences, he completed his postdoctoral fellowship in medical simulation at the Department of Imaging of the Massachusetts General Hospital and Harvard Medical School in Boston. He is an instructor at the Harvard Medical School and a former Visiting Professor at the University Campus Bio-Medico of Rome. He is also Director of the Medical Device and Simulation Laboratory at Massachusetts General Hospital.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product