Commissioned OEM Eisenmann alpha-tec regularly automates complex railway-oriented applications with industrial robots and is familiar with the latest developments on the 7th-axis market. That's why they use the world's first composite concrete 7th axis from IPR

World’s First Composite Concrete 7th Axis used for the First Time In Series Production at Car Manufacturer

World’s First Composite Concrete 7th Axis used for the First Time In Series Production at Car Manufacturer

Case Study from | IPR Robotics, LLC.

The 7th axes for the paint shop of a large car manufacturer should be more efficient, economic, and sustainable. Commissioned OEM Eisenmann alpha-tec regularly automates complex railway-oriented applications with industrial robots and is familiar with the latest developments on the 7th-axis market. That's why they use the world's first composite concrete 7th axis from IPR - Intelligente Peripherien für Roboter GmBH with many advantages compared to existing metal variants. This is the first, time, this innovative 7th axis technology is used in series production. Wherever space is at a premium, noises and vibration must be reduced, the new 7th axis made from composite concrete offers a very cost-effective solution with an outstanding life cycle assessment. The four composite concrete models introduced so far are suited for 95 percent of the industrial robots on the market.

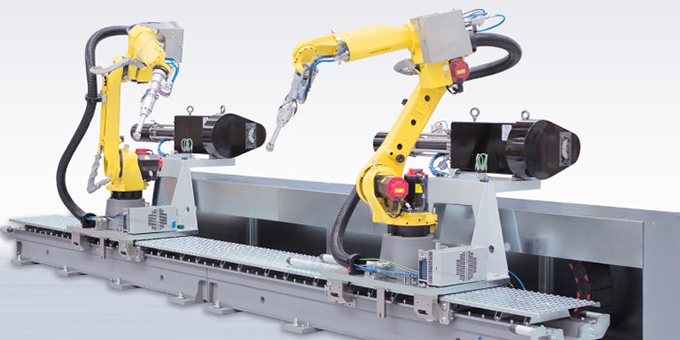

Seven 7th axes with a total length of 39.5 meters and nine carriages for the same number of robots are used at the German car manufacturer in cavity preservation and seam sealing with three more axes being requested. The challenge: They must run without problems with all auxiliary modules in automatic mode.

This is precisely where Eisenmann alpha-tec comes in with their service package: The system partner assumes responsibility for preparing the technical specifications, designing the system, its installation up to commissioning of mechanics, industrial robots, application and dosing technology, material supply and conveyor technology. This way, the OEM ensures that their customers can concentrate on what they do best – their core business: producing cars. The seven 7th axes with a base body made from composite concrete are a central component of the automated solution and fit for series production. The composite concrete was purposefully developed for use in different industries. It has a property profile that is tailor-made for production and handling - for example, it is low-vibration and quiet. In addition, the entire product line is silicone free and can therefore be integrated in special areas such as this paint shop without any concerns. The successful tests at the independent materials testing center in Kaiserslautern confirm the suitability for production: The composite concrete 7th axis was subjected to a continuous load test with 2.5 million cycles – this corresponds to an operating time of about ten years. IPR’s design calculations have been confirmed in the endurance test and show the same reliability as models made of aluminum or steel.

The developers at IPR placed great value on material sustainability. Here, the figures speak for the innovation as well: Approx. 75 percent less CO2 and 90 percent less energy required compared to a 7th axis base body made of steel. “We have already worked together with IPR in a trusting and successful manner in other joint projects. We value the expertise of our partner and the reliability, also with respect to the timing and the smooth implementation of individual customer requirements,” says Stephanie Lücking, Project Manager at Eisenmann alpha-tec. IPR built the first 7th axis in 2006 and is an innovative expert in this field. Ceiling-mounted, wall-mounted, vertical, floor-mounted 7th axes and 7th axes with coaxial extension made of composite concrete, aluminum, and steel offer movement solutions in the assembly and handling technology, for loading and unloading units, as well as paint applications. The modular systems of different sizes have a payload of up to 12 tons and can be flexibly extended. The length is practically freely selectable. To date, IPR has sold over 1,500 7th axes worldwide.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product