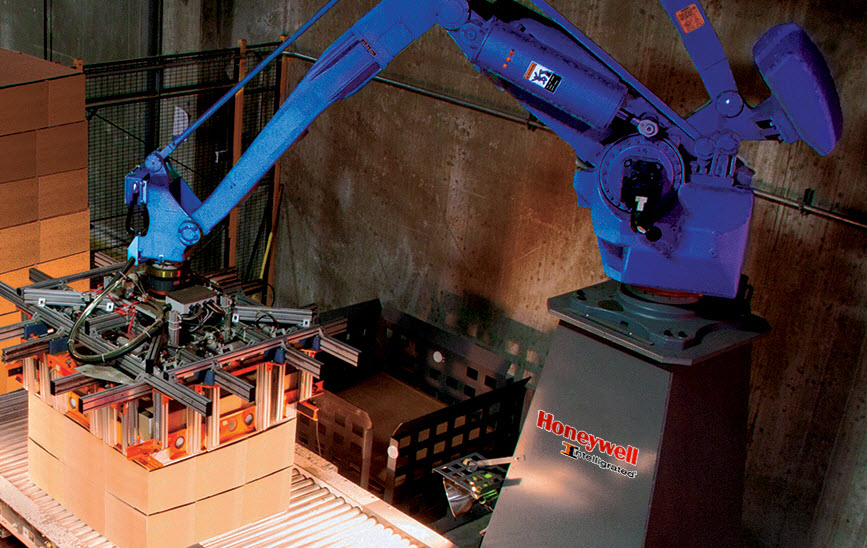

This year, we’re demonstrating new robotic palletizing and depalletizing solutions, now available with advanced diagnostics and predictive failure capabilities to improve throughput rates and uptime of mission-critical production operations. Booth #C-3136.

PACK EXPO Q&A with | Honeywell Intelligrated

Tell us about your company.

Honeywell Intelligrated designs, manufactures, integrates and installs complete material handling automation solutions, including conveyor, IntelliSort® sortation, Alvey® palletizers, Honeywell Robotics, automated storage and retrieval systems, and voice-directed picking technologies — all managed by advanced machine controls and our best-in-class Momentum™ warehouse execution system. Honeywell Intelligrated’s Connected Distribution Center is designed to help companies make the digital transformation from manual to automated processes and keep up with the rapidly escalating pace of modern commerce demands. Through the seamless integration of sensors, controls, automation and labor, we’re providing the real-time business intelligence to help our customers make informed business decisions, ensure worker safety, and maximize equipment uptime and lifecycles. We back every project with 24/7 multilingual technical support and access to lifecycle support services through a network of national, regional and local service centers.

Your company will be exhibiting at PACK EXPO, what is it that makes this an important event for your company?

We always look forward to the event. It presents an opportunity to engage with end-users while driving awareness of our latest initiatives, including innovations in warehouse automation, robotics, voice-directed technologies and connected solutions for automated palletizing equipment. We’re able to showcase our latest hardware and software solutions, demonstrating new technology in a forum filled with other industry leaders and influential media – illustrating how Honeywell Intelligrated is helping to shape the future of warehouse management, smart robotics, palletizing and order fulfillment. It also provides a forum for us to discuss with customers and partners solutions to the challenges facing the industry right now including the increasing throughput, labor staffing issues and the need for better visibility into operational performance.

What makes your booth a must visit for PACK EXPO Attendees?

The Honeywell Intelligrated booth at PACK EXPO gives us the chance to showcase and demonstrate solutions that illustrate our commitment to alleviating the burden of intense pressures facing manufacturing operations today. Whether it be helping operators identify and address potential issues before they impact productivity, or improving palletizer utilization and throughput rates – we always look forward to this opportunity to highlight what’s next in connected offerings.

This year, we’re demonstrating new robotic palletizing and depalletizing solutions, now available with advanced diagnostics and predictive failure capabilities to improve throughput rates and uptime of mission-critical production operations. We’re also featuring demonstrations of voice-guided solutions incorporating mobile robots in collaboration with Fetch Robotics. These autonomous mobile robots will receive and transport cases to predetermined locations within the booth – while visitors learn how voice software can be used to perform guided preventive maintenance to prevent downtime.

Finally, visitors may participate in an interactive demonstration of TechSight – an augmented reality maintenance solution to help decrease unplanned downtime while reducing service costs.

PACK EXPO has many educational sessions, forums and demonstrations, is your company involved in any of them this year?

This year, the Honeywell Intelligrated booth will host a number of demonstrations showcasing a variety of technologies. New robotic palletizing and depalletizing solutions will be showcased, as well as a demonstration of voice-guided mobile robots in collaboration with Fetch Robotics. Visitors can also participate in an interactive demonstration of TechSight, an augmented reality maintenance solution.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. that you plan on attending?

We’re excited to see new solutions in action and see the latest in innovation-driving technologies like AI and robotics that are helping warehouses and distribution centers drive cost savings, increase operational efficiencies and provide a competitive edge.

The factory floor is undertaking rapid advancements, be it automation, robotics, machine vision or data. Automation Technology is a huge part for many manufacturers; give us an idea on how your company and product is being utilized now in the smart factory.

Through technological advancements - including robotic palletizing and depalletizing solutions, autonomous mobile robots and voice-guided technologies for workers - and strategic collaborations with the likes of Fetch Robotics and Soft Robotics and Carnegie Mellon University, Honeywell Intelligrated is working to find practical solutions for the industry’s most vexing challenges.

For instance, we are collaborating with the National Robotics Engineering Center at Carnegie Mellon University – leveraging artificial intelligence (AI) and robotics to improve productivity and ease labor challenges by developing next-generation architecture to control and operate multiple robotics applications through machine learning. These solutions enable critical decision-making capabilities, intelligent motion, collision avoidance and reliable sensing to improve overall operations and productivity.

We are also helping manufacturers and distribution centers harness the power of the Industrial Internet of Things to deliver real-time asset monitoring, historical trends and predictive analytics to improve their operations. With machine-level sensors and software, customers can detect and predict risks and opportunities with advanced analytics to help reduce downtime by identifying potential issues before they become problems.

Give us your thoughts on what the future holds for manufacturers and automation technology.

Warehouses and distribution centers are fast-changing, so further advancements in technology such as robotics and automation are sure to continue to disrupt operations. Areas with the potential to unlock rapid innovation include AI and machine learning – specifically, applied to robots and connected technology. As robots become more autonomous and intuitive through machine learning, warehouses can deploy them for a host of functions currently carried out manually – freeing workers for higher-value jobs throughout the industry.

The same technologies are also driving a new generation of robotic unloaders – such as our own – which go beyond the capabilities of robotic arms to unload trailers in half the time of manual processes without any fleet modifications. These technologies will continue to boost productivity while reducing injuries – allowing management to increasingly redeploy labor, increasing worker job satisfaction and retention.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product