Their client needed a conveying solution integrated into their current facility. The over-sized product, an aircraft wing support beam, needed to be handled incredibly carefully to avoid product damage.

Flexible Conveyor Manufacturer Glide-Line Overcomes Space, Size, & Product Handling Constraints for Aerospace Industry Integrator

Flexible Conveyor Manufacturer Glide-Line Overcomes Space, Size, & Product Handling Constraints for Aerospace Industry Integrator

Case Study from | Glide-Line

Here at Glide-Line, we make conveyors - specifically, flexible, configurable conveyors built to very specific measurements to fit limited spaces which can be configured with a “zero product to product contact” design philosophy, all with impressively short lead times. We’ve noticed three trends in the past year that are creating demand for what we have to offer:

Manufacturers need completely configurable, not singular-use, equipment.

“People have been asking for versatile equipment they can use for a variety of products in various sizes and shapes. Within the same facility, they’re integrating conveyors to suit multiple product shapes, carton, pallet and tote sizes, and packaging types, and it is easiest for manufacturers to use equipment from a single manufacturer that can meet these varying product demands,” says Trevor Price, Lead Application Engineer for Glide-Line.

As a manufacturer of highly configurable, flexible conveyors suitable for conveying a huge variety of product and pallet sizes, we’ve seen demand increase in line with this trend. Our conveyors are all configurable to one-millimeter increments, with no set standard sizes our customers need to adhere to.

Manufacturers are looking for ways to reduce costs by preventing product damage.

Preventing product damage during the manufacturing process is one way integrators are being asked to impact ROI. We’re able to best assist in meeting this demand with our conveyor that implements individually-controlled conveyor sections to eliminate product-to-product contact, control product distance, and efficiently operate each zone only as required. This is achieved using our DC motor/controller set-up or using VFDs with our AC motors. Each individual zone has its own motor, so the ability to transport heavy loads is uncompromised.

Manufacturers are pivoting to meet demands faster, so they need speedy delivery.

Integrators have always been impressed with our fast lead times, but in the past year, we’ve seen an uptick in requirements for meeting quick turnaround times that can enable integrator clients to deliver solutions quickly, allowing for the client to pivot and meet demands much faster than in the past. Our lead times are always 6 to 8 weeks, significantly faster than those of our competitors.

About the client: aerospace industry automation systems integrator

These trending demands recently came into play for a project we worked on for a large automation systems integrator working in the aerospace industry. Their client needed a conveying solution integrated into their current facility. The over-sized product, an aircraft wing support beam, needed to be handled incredibly carefully to avoid product damage.

“We chose Glide-Line because of their customizable conveyor products and world-class customer service. Their engineering team solved the issues we faced without batting an eye, and our customer was thrilled with the result.” - Project Engineer

The client’s request

Our integrator client was challenged with:

-

Unique product size/weight: At 12 feet long and 150 pounds(!), our biggest challenge was providing a conveyance solution for a very long product. This product exceeded any standard pallet size, so a custom solution was required. Because our whole line of conveyors is configurable, including sizing available in one-millimeter increments, we were able to accommodate this build with some simple modifications.

-

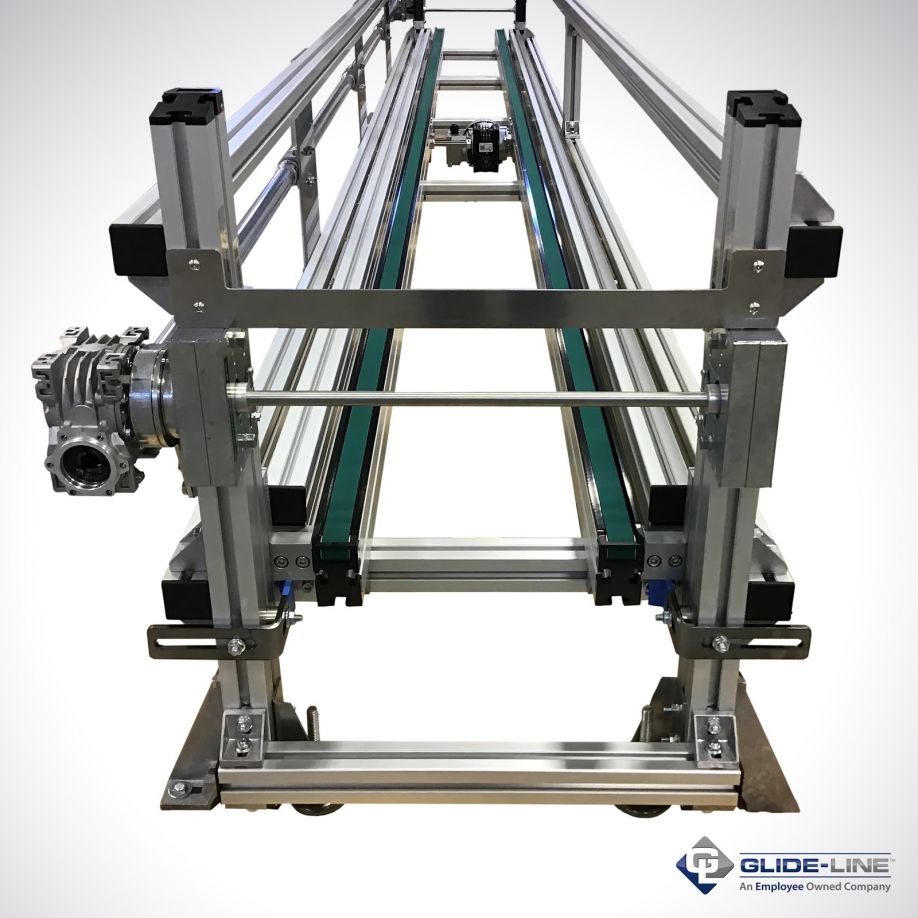

Space limitations: Our system was being placed between existing systems, so we had a little over the width of the pallet (~1.5 feet) in which to incorporate a solution. We recommended an over/under-style conveyor to maximize the space. We configured our conveyor to match the width of the product to safely transport it along the way.

-

Ensuring no product-to-product contact: We needed to provide a solution that would eliminate product contact to ensure the product is not damaged during the automation process. Our Zero Contact Zoned Conveyor configuration was perfect for this demand, since its individually-managed accumulation zones ensure there is always a gap between products. With the use of VFD controls on the motors, the conveyors could transport product to each stop location, without the use of a physical stop, which could otherwise cause damage to the product.

The solution

The flexibility of our conveyors was the key to solving these challenges. Our solution combined three variations on our equipment to create the conveyor system their client was looking for.

-

Our configurable designs allowed for the footprint of the over/under-style conveyor to be optimal for the space.

-

We integrated our zero contact individually-managed accumulation zones, without the use of a physical stop, to control acceleration and deceleration.

-

We configured a conveyor system with our Vertical Transport Units (VTUs) to act as the elevator between an upper and a lower conveyor section. (Yes, we designed a VTU for a 12-foot long pallet.)

Unforeseen obstacles

It became clear that traditional Lift and Transfer Units (LTUs) would need major modifications to work with this size and weight product. Since we were already using Vertical Transport Units (VTUs) as an elevator, we adapted our VTU to act as a 90-degree Lift and Transfer at the same time. By rotating the deck conveyor of the VTU 90 degrees, this VTU can also function as a transfer by lifting the product up, off the main line, and conveying it onto a perpendicular spur line for station work.

Due to the large size and weight of the product, we added additional bracketry and support to prevent sagging of the conveyor deck. We also changed to custom shafting due to the extra length. Our engineering team worked quickly to increase the capacity of the unit--in a single day. With the approval from the customer, we fabricated the parts less than 24 hours later.

Additionally, we were asked if we could supply a particular brand of bearing that our customer wanted to use, as opposed to our standard bearing. We provided all the information needed for them to properly determine the appropriate bearing model. They supplied us with the bearings to use during the build. This is just one example of the collaboration we needed to help make the project a success.

Bringing it together

A last-minute change in our customer's production schedule led to a final hurdle: we were asked to ship a portion of the system even earlier than the original contract date. Though we were already on a tight time schedule, our team worked hard to produce the partial shipment ahead of schedule to allow our customer a head start in assembly before shipping the rest of the project on time.

In just eight short weeks from initial conversation to the first product completion, we were able to collaborate with our integrator customer and their client to make the project a resounding success. We faced unique challenges in the product size, space limitations, and product handling needs, and our proven flexibility, configurable product line, and ingenuity in providing solutions for manufacturers made for an enthusiastic customer. “Glide-Line is based on innovation, excellent customer service, high quality and real speed,” said Kevin Mauger, President of Glide-Line. “This type of project is the reason we exist, and we’re happy to help them see success.”

About Glide-Line

Glide-Line, an employee-owned company, offers the most versatile multi-strand pallet and panel-handling solution available for the automation industry. We are the future of conveyor system manufacturing. We pride ourselves on making our integrator clients’ automation layout design process as easy as possible.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product