While alignment may be within acceptable tolerances during installation, deflection due to loads and thermal expansion or contraction may lead to misalignment. The use of an appropriate flexible coupler can compensate for such minor variations in alignment.

Speed Reducers & Proper Shaft Alignment for Motion Control Applications

Article from | Motus Labs

Regarding Shaft Misalignment

When installing speed reducers in a motion-control application, careful alignment of the input and output shafts is of utmost importance. Mounting surfaces should be flat and even to ensure equal bolt pressures and avoid angular tilting of components. While alignment may be within acceptable tolerances during installation, deflection due to loads and thermal expansion or contraction may lead to misalignment. The use of an appropriate flexible coupler can compensate for such minor variations in alignment.

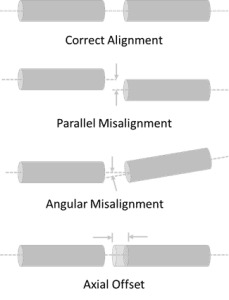

Proper alignment of shafts is the positioning of the rotational centers such that they are co-linear under normal operating conditions. Shaft misalignment can occur in the axial and radial directions as illustrated.

Parallel misalignment is the result of shear displacement with respect to the z-axis and is also referred to as offset, rim or radial run-out. Angular misalignment, sometimes referred to as angular run-out or face, is the difference in slope between the centers of rotation. Axial offset is the result of compression or expansion along the z-axis and is often the result of thermal variations.

Implications of Shaft Misalignment

Shaft misalignment can generate large forces that produce stress on components in the drive train and can result in unwanted vibrations. In particular, bearings and seals can be impacted by these forces. Excessive misalignment can result in lubricant leakage and excessive seal wear, as well as excessive preload on supporting bearings. While these forces on bearings may go unnoticed initially, they can result in premature bearing failure due to flaking or pitting of the balls or races, or failure of the cage. Harmonic resonances resulting from misalignments can result in excessive vibrations and even larger stresses on critical components.

While excessive misalignment should be avoided by the correct and careful mounting of components, flexible couplers can play an important role in correcting for residual misalignment. Depending on the type of coupler used, the purposes served may include:

- Efficient and precise transfer of torque

- Absorption of residual misalignment

- Dampening of vibrations

- Torque limiting/fail-safe

Coupling Considerations

The selection of a proper coupling for a motion-control application requires consideration of numerous performance factors that must be taken into consideration for the coupling to work properly. These factors include including torque levels, the type and amount of shaft misalignment, inertia, torsional stiffness, rotational speed, space requirements, and others. Before selecting a coupling, it is necessary to know the specifics of these issues for the application for which the coupling is to be used. A large variety of servo couplings are available, each with its own strengths and weaknesses.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product