If you currently manufacture industrial vehicles, such as forklifts or tow tractors, vehicle automation could open a new revenue stream. But it's a big project, and getting it wrong could prove to be an expensive exercise.

5 Things to Consider Before Creating an Automated Vehicle System

Article from | BlueBotics

1. AUTOMATE AN EXISTING MANUAL VEHICLE OR BUILD AN AUTOMATED VEHICLE SYSTEM FROM THE GROUND UP?

- Adding automation to an existing vehicle may be more cost-effective than creating a new vehicle from the ground up, at least during the prototyping stage. When moving into production however, you may find this adds unnecessary expense as some parts – such as the steering wheel if creating a non-hybrid vehicle – may not be necessary.

- Creating a new vehicle may allow you to add extra functionality (on top of autonomous navigation), such as a conveyor belt or robotic arm.

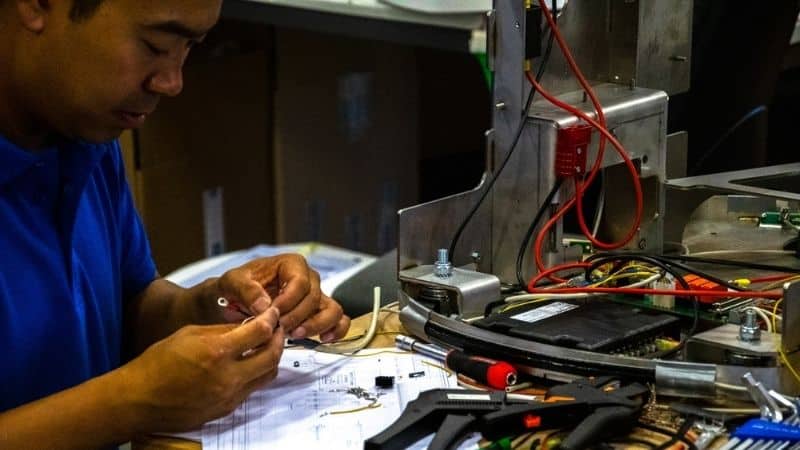

Keep in mind that not all hardware can be automated smoothly. Some manually-driven vehicles may not readily accept automation; for example, drive technology and control systems may need to be replaced with new versions that are easier to automate.

Tip: Define what features your automated vehicle system will need, and which of its existing components are not automation-ready. This will help you assess whether you can add automated guidance easily, or whether it would be better to start from scratch.

Not all hardware readily accepts automation; some parts may need to be swapped out.

2. WHAT TYPE OF AUTONOMOUS NAVIGATION TECHNOLOGY?

When it comes to your vehicle knowing its position and moving autonomously around a customer’s site, what type of navigation technology will you choose for your new offering – physical line following, laser guidance, natural navigation, or another type of guidance? Each different technology has its pros and cons, with natural navigation being the most flexible and robust option.

You should also consider connectivity. A vehicle’s routes and actions (i.e. lift forks) can be pre-programmed and saved onboard the vehicle (what we at BlueBotics call ’embedded mission control’), but if part of a larger fleet your vehicle will need access to wireless communication in order to communicate with its fleet management server software and infrastructure, such as automatic doors and elevators. The strength of signal required depends on the type of navigation technology in question.

Vehicles driven by ANT technology, for instance, do not require constant WiFi access when performing their individual roles – a low-bandwidth connection is only required in order to interact with infrastructure or other vehicles in a fleet.

Tip: Investigate the pros and cons of different navigation technologies to decide the best fit technology for your vehicle.

3. IS YOUR TEAM AUTOMATION-READY?

Gaps in your team’s knowledge can cause costly mistakes (like installing a component that cannot be automated), or lengthy delays (as your team scrambles to upskill).

It is therefore worth taking the time to find out exactly what skills are needed to create an AGV, while honestly evaluating what your team is capable of.

Does your team have the skills required to automate a vehicle?

Even if you have all the required knowledge in-house you might still want to build out a larger team, because if you have only a single point of knowledge for your AGV project, it could grind to a halt if that team member leaves. And while your team may have all the skills to handle the complex mechatronics work involved, that does not mean they have the time to do so. You might need to put other projects on hold in order to add automated vehicles to your portfolio.

Finally, consider the need for technical post-sales staff who can travel to customer sites to actually commission your AGVs. If the staff you send to get your customers’ AGVs moving are the same people who developed them, this will of course slow down any new development work. It may therefore be more efficient to build out a separate team to handle installations and future client project updates.

Tip: Make a list of the skills and know-how you will need for your project, then compare this list to the team you already have. Does your team have the skills, or can existing team members be upskilled? Don’t forget post-sales support.

4. POWER UP

While scoping out a good-fit battery system, keep in mind not only battery life and charging times but the charging system itself. Do you prefer an automatic charging system into which your AGV can drive to recharge itself (more complex, but lights out-ready), or a system that needs to be plugged in manually by a team member, which will be less complicated to design but more complex for your customers and not capable of running 24/7?

Tip: Scope out the different types of power systems available – you may find that the availability of parts makes the decision for you.

5. PICK THE RIGHT AUTOMATION PARTNER

It is no exaggeration to say that your choice of automation partner can be the difference between a successful vehicle automation project and an expensive, time-consuming experiment.

When researching suppliers, first check how long they have been in business, so you can feel confident you are not their very first customer. Ensure they have worked on vehicles and applications similar to yours, and ideally that they have staff based close to you for more convenient support (or alternatively, staff who are happy to travel to you as required). What about existing customers: are you able to speak with any direct?

BlueBotics’ ANT navigation technology today drives more than 3,000 vehicles around the world and has been proven in industrial settings for over a decade.

Just some of the more than 3,000 vehicles which are driven by ANT navigation.

Tip: Make a list of potential automation partners and check their references carefully.

READY TO GET STARTED?

If you’re ready to take the next step on your automation journey, explore ANT technology, or get in touch to discuss how we can help you add automation to your vehicle portfolio.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product