The teams at Enchanted Tools aim to revolutionize robotics by improving the acceptability of robots to promote their large-scale adoption. We take a look back at the origins of a project that is ambitious in many respects, and one in which maxon is proud to participate.

Mirokaï, A Revolution in Robotics

Mirokaï, A Revolution in Robotics

Article from | maxon precision motors inc

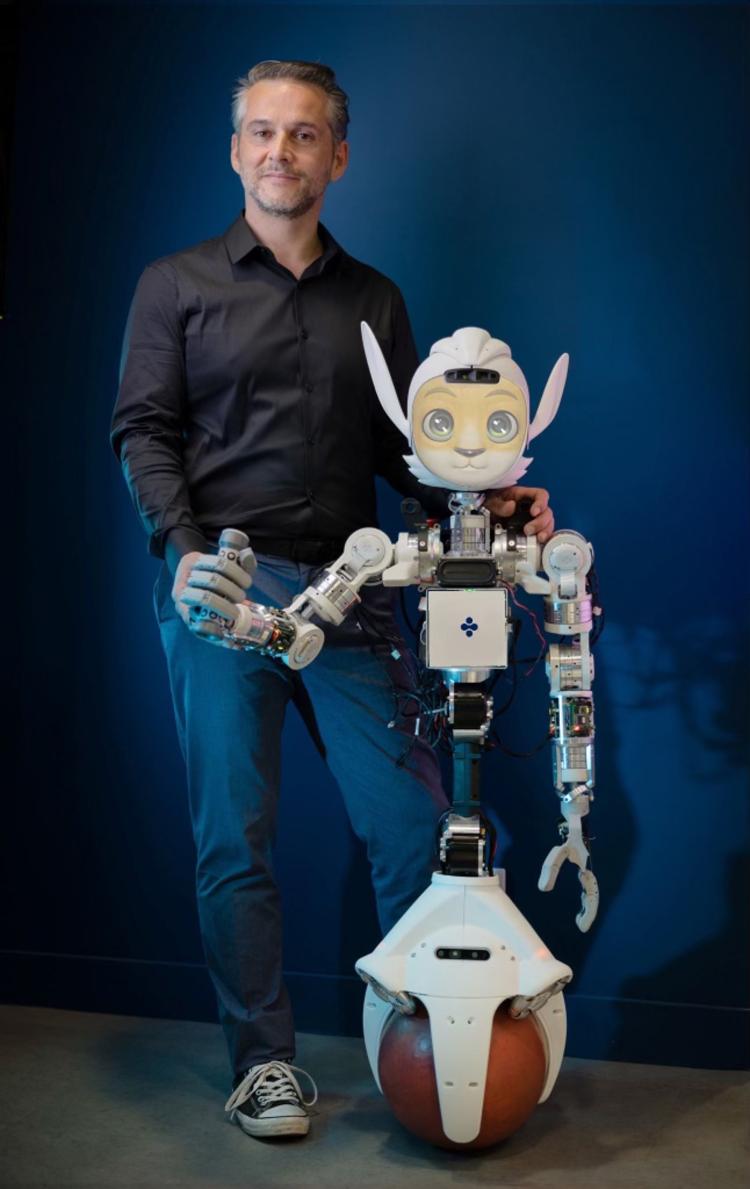

How can we fully integrate robots into our daily lives in the near future? This challenge is currently being addressed by French startup Enchanted Tools. Founded by Jérôme Monceaux, who had already helped create the robots Pepper and Nao, Enchanted Tools recently unveiled Miroki, the prototype of a new generation of humanoid robots that are both wondrous and useful.

Miroki is an endearing robot character. Half-child, half-animal, this little fox-like creature from outer space has been given an extra element of soul, with a strong backstory and convincing character design, developed with the help of French animation expertise. Ultimately, Miroki could be used in the medical sector, in hospitality, or in airports, to relieve personnel of exhausting logistical tasks.

Because they believe that robotics can re-introduce a touch of enchantment to the world, rather than dehumanizing it, the teams at Enchanted Tools aim to revolutionize robotics by improving the acceptability of robots to promote their large-scale adoption. We take a look back at the origins of a project that is ambitious in many respects, and one in which maxon is proud to participate.

Miroki : a robot character with a backstory

Far, far away in the cosmos, there is a planet inhabited by benevolent beings who have achieved a state of harmony. These creatures of light, the Mirokai, have guided humanity along the path of otherness since the dawn of time. From cave paintings to the first writings and melodies, they have inspired us down through the centuries. Now, for the first time, one of them has passed through the portal that separates our two worlds to come to our aid in person. “I'm not perfect, but I'll do my best,” Miroki solemnly declares in a presentation video, before jumping into space and entering our reality. His spirit then slips into a kind of spacesuit: the robot prototype developed by Enchanted Tools. Now Miroki has come into our lives.

To create social bonds and a sense of unity, people have always told stories to each other. With this in mind, Enchanted Tools pooled the creativity of animation experts and industrial designers to change how we think about robots. “With this approach, we were able to create a robot with personality, a robot with a depth that no machine has ever had. This is a disruptive and innovative approach to robot design,” says Jérôme Monceaux, CEO of Enchanted Tools. In addition to creating a backstory, Enchanted Tools also asked artists to animate Miroki's face. The interactive facial expressions are video-projected and animated in real time.

The startup worked with Gaumont to bring the Mirokai universe to life on the big screen.

Miroki: the perfect balance between the strange and the familiar

Have you heard of the “uncanny valley” concept? Developed by roboticist Masahiro Mori, it refers to the sense of unease that we feel when confronted with a humanoid creation that looks too much like a human. The idea is that the more similar a robot is to a human being, the more freakish its imperfections seem to us. Conversely, when a robot is sufficiently non-humanoid, it is the human features that catch our attention and incline us to empathize with something that is clearly identifiable as a machine.

Interaction, navigation, and gripping: a robot designed to be useful

Pepper and Nao, Jérôme Monceaux's first two creations, have the distinction of being the first humanoid robots to achieve popularity in the world. Nevertheless, these two robots did not succeed in becoming part of everyday human life, because they were not “useful” enough. For Miroki, the challenge was therefore not only to create a robot that people would accept, but also one they would find useful. This meant meeting three challenges of robotics.

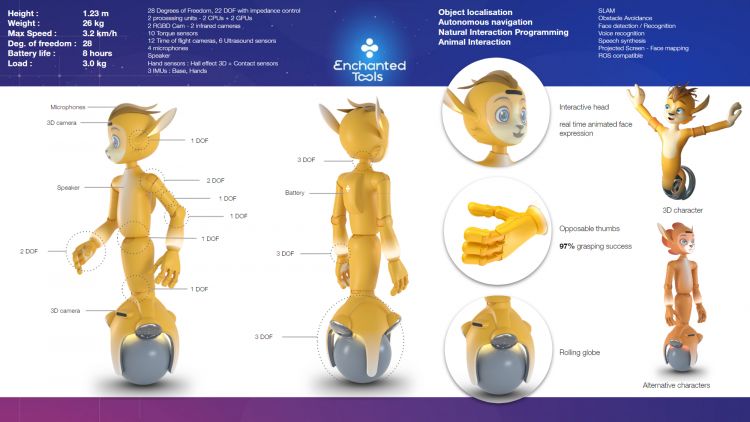

- Automated navigation in semi-standardized spaces. Perched on a rolling ball, Miroki moves – and can be moved – in any direction. If he gets in the way, just a gentle push with a finger will make him roll away, whereas a two-legged or track-mounted robot would need to be lifted. Miroki is easy to use and to handle, which is an essential feature for mobility in social and work environments.

- Automated gripping of objects. Miroki's hands are uniquely designed to grip special handles – or “runes,” to continue the fantasy narrative – that users can attach to objects they want the robot to lift. The radical simplicity of this all-purpose handle allows Miroki to achieve a 97% grip success rate, whereas the market standard is about 60%. This is essential, because a tool that fails half the time can never be satisfactory. That is why Enchanted Tools chose to adapt the environment to the robot, making it intelligent.

- Semantic and emotional interactions with untrained users. Miroki is capable of the level of interaction required to functionally understand and execute voice commands.

“Miroki was designed with the aim of simplification: he is not the best at gripping, navigation, or interaction, but he is good enough in all three areas to accomplish his task, which is to move objects within a social environment.” explains the CEO of Enchanted Tools.

From hospitals to hotels: for use in a variety of environments

Hospitals, retirement homes, airports, trade shows, hotels, restaurants… With the ability to carry loads up to 3 kg, Miroki can be of use in all kinds of hospitality, transit, and leisure venues where staff recruitment can be difficult and where human interaction must take priority over logistics.

The all-purpose handles used by Miroki work with tags to make objects grippable and to identify spaces. In the future, it will be possible to equip all the rooms in a hospital ward with these sensors. A nurse will be able to prepare various breakfast trays and simply say to the robot: “This is Mrs. Martin's tray. Every morning at 8 a.m., I want you to take Mrs. Martin's tray to room 103 and bring it back at 9 a.m.” and the robot will do it. Or the nurse can ask the robot to bring back by midday all the trays that have not been put away. By means of simple voice instructions, the robot will be able to carry out tasks to make people's lives significantly easier.

Miroki: a technological challenge met in less than a year by 50 engineers

maxon's teams then assisted Enchanted Tools with product design and in selecting the motor types, taking into consideration the technical constraints and the very tight deadlines required for the presentation of this new robot. ECi 40 motors with planetary gearboxes were chosen for the ball bot, while 22-mm diameter brushless motors from the ECX Torque range were used on the other axes.

Kevin Schwartz, sales engineer responsible for Enchanted Tools at maxon France, and Max Erick Busse-Grawitz, Technology Transfer Manager at maxon International, explain: “Because the application was in the area of autonomous robotics, where the systems need to support themselves, and where the actuators are consequently both part of the solution and also part of the problem (due to weight, inertia, and size), we proposed motors with high power density and a high torque-to-inertia ratio, in other words, a low mechanical time constant, and gearboxes with high efficiency and high torque density.”

ECX Torque 22mm

ECi 40mm

Through many telephone calls and on-site meetings, maxon's teams worked closely with the technical teams at Enchanted Tools. Step by step, the Enchanted Tools teams narrowed down their needs and worked out new specifications axis by axis. Building on the success of the prototyping phase, maxon is now assisting the startup with the analysis of these new specifications, to define the best possible technical solution for the industrial production phase. The objective is to achieve a balance between technical performance and production cost.

“We needed partners who could supply components on time that would be reliable, robust, and suitable for the needs of R&D. What we appreciated in maxon is the DNA of the company: hard-working people making trustworthy products that inspire confidence and are scalable,” says the CEO of Enchanted Tools.

After successfully presenting its first prototype, Enchanted Tools intends to conduct a second round of fundraising in 2023 to start the production of its first models. Once operational, the Mirokai will be subjected to real-world conditions so they can learn and improve, which will make them more and more useful. A partnership has already been established with the AP-HP Broca hospital in Paris, which specializes in geriatric medicine. Enchanted Tools plans to have its robots on the market by 2025-2026. Its target is to produce 100,000 robots in 10 years. “Our robots are designed to fit into people's lives quickly, with no false promises,” says Jérôme Monceaux, CEO of Enchanted Tools. So get ready to see a little rolling fox offering you a refreshing beverage very soon!

To keep following the Enchanted Tools story: https://enchanted.tools/

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

Other Articles

Multi-axis motion control drives pipe-based robots

Automate 2025 Q&A with maxon group

Understanding Torque and Speed in Electric Motors

More about maxon group

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product