While it’s hoped that figures will have changed since the IFR’s previous report, the gap between the UK and other countries shows there’s still a clear need to drive up robotic adoption.

What’s Holding Back Robot Adoption? - With the UK Lagging Behind Its Competitors, What Needs to Change?

What’s Holding Back Robot Adoption? - With the UK Lagging Behind Its Competitors, What Needs to Change?

Dave Walsha, Sales manager | EMS

The most recent statistics from the International Federation of Robotics (IFR) found that the UK has approximately 101 robots per 10,000 employees. With the world average cited at 126 units, it’s clear that the UK is lagging far behind its competitors when it comes to embracing robotic technology. Here, Dave Walsha, sales manager at DC motor supplier EMS, explores the factors holding back robot adoption, and what needs to change to get things on track.

While it’s hoped that figures will have changed since the IFR’s previous report, the gap between the UK and other countries shows there’s still a clear need to drive up robotic adoption. Despite living in an era where buzzwords like automation, digitalisation and AI are everywhere, these trends don’t appear to have been implemented as quickly as one might expect.

There are some sectors that have taken to automation technologies more readily than others. The automotive sector — the UK’s biggest user of industrial robots — hit a global milestone this year with one million units reported to be in operation. But what about areas that haven’t adopted robots so readily — what’s holding them back?

Financial concerns

For many, the financial cost of robotics is a major barrier to adoption. Not only is there the cost of the robot itself to consider, but also the need for staff to be trained appropriately. The potential disruption to product lines and processes while robots are still being implemented is another factor that can make it hard for businesses to accurately predict and understand their ROI.

However, there are routes available for those who wish to try robotic technologies without the upfront cost. This comes in the shape of Robotics as a Service (RaaS), which enables companies to hire robots rather than purchasing them outright.

The flexible nature of RaaS means that businesses of all shapes and sizes can trial automation technologies. And without the same financial commitment, it offers all the benefits with minimal risk. Businesses who experiencing changing demand throughout the year can also benefit, with the freedom to hire additional robots as and when needed.

Ease of use

Another major concern in the use of robots is their ease of use. How easy are they to program, and how quickly can they start working and producing meaningful results? If robots are expected to work on a much more integrated level with humans — working alongside them rather than in separate areas — the way that they can be instructed should reflect that.

This means that giving the robot commands shouldn’t require extensive programming knowledge or take a lot of time. It must be quick and user-friendly — if it takes too long to ask the robot to do something, then the operator may just end up doing it themselves. Making the most of natural language processing technology and AI is essential in giving the robots the ability to understand and carry out the instruction efficiently.

Functionality

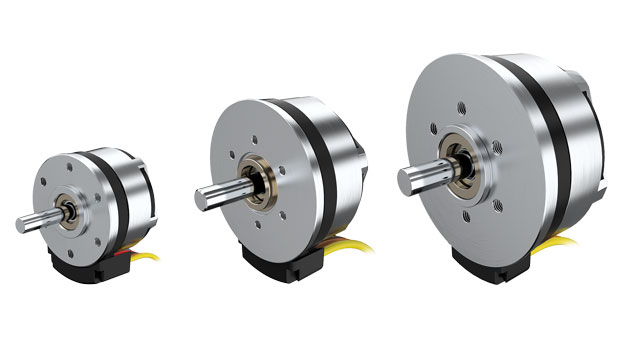

The hardware must also be up to scratch. Robots rely on a variety of DC motors to facilitate their movements, and it’s important that each one is selected with careful consideration. What are the power requirements? How much space is available? Will the motor be operating for extended periods?

Surgery robots, for instance, must be compact and able to operate with extremely high precision. They also need to be highly dynamic in order to change position smoothly, and quickly react to changes in load while holding an exact position.

Developments in DC motor technology mean that it’s possible to meet these requirements in ever-decreasing packages. Choosing a brushless DC motor over a brushed alternative often results in a more compact motor. And for applications with strict size requirements in one axis, ultra-flat motors are available. FAULHABER’s BXT flat motor series, for example, features an innovative winding technology that allows it to offer torques of up to 134 millinewton metres with a maximum diameter of 42 millimetres and a length of just 22 millimetres.

High resolution encoders help to support dynamic acceleration and deceleration, by providing the increased level of feedback necessary for more sophisticated control. And it’s possible to integrate these encoders, as well as speed controllers, within the housed motors for improved control while minimising drive system size.

Careful consideration of each motor combined with the integration of additional sensors into the drive system allows for more sophisticated robots, with all the functionalities required for their specific task. And taking such a design approach means that end-customers are more likely to end up with robots that meet all their expectations and more; a sentiment that will be crucial in growing robotic adoption.

Risks, rules, and regulations

Before any new robot installation, there are some ethical and legal questions that must be answered. What risk could the robot pose to a human in the case of an error or shutdown? Who is responsible for these errors?

Relevant laws must be evolved and developed to meet these concerns. Emphasis in health and safety legislation is still very much on the employer to ensure safe conditions for all, but there’s still no explicit mention of robots.

Furthermore, while it’s possible to test what’s essentially the hardware of the robot and prove its compliance with existing legislation, what about its ‘thinking’ capabilities? For the robots of the future, this is only likely to become a growing issue. We’re still waiting on what AI laws could look like, but the scope of these will certainly be a concern to both robotic manufacturers and customers alike.

Potential and future adopters might be relieved to hear that there are solutions to their concerns around robotics and automation. But with the underlying technologies developing at an unprecedented pace, it’s clear that we must start making use of the latest and greatest tools if we’re to compete on a global scale. Giving the UK a competitive edge is only possible if it takes advantage of these opportunities — before it’s too late.

EMS is a leading supplier of DC motors in the UK & Ireland. As an exclusive distributor for companies including FAULHABER, Nidec and Bühler Motor, EMS has the partnerships to specify the motors to meet even the most demanding requirements, including robotic applications. To find out more, please get in touch with a member of the team here.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product