Manufacturers currently use automation to streamline workflows, enhance efficiency, cut costs, and meet growing consumer demands. Yet they face a myriad of disruptions such as labor shortages, limitations of current technologies, and costly downtimes on production lines.

Physical AI: Embracing AIs Moment in Robotics

Physical AI: Embracing AIs Moment in Robotics

Kristi Martindale, Chief Commercial Officer | Palladyne AI

A revolution is brewing in the robotics world. The rise of physical AI is having its breakthrough moment, like ChatGPT did in language processing in 2022. The hottest topic at CES 2025, physical AI, is being hailed as the “ChatGPT moment” for robotics as AI combines with advanced robotics to make a sea change in automation across industries.

Many manufacturers currently use automation to streamline workflows, enhance efficiency, cut costs, and meet growing consumer demands. Yet they face a myriad of disruptions — such as labor shortages, limitations of current technologies, and costly downtimes on production lines — that negatively impact the bottom line.

Physical AI will enable these companies to automate tasks that historically have been too complex to automate. Though robots and automation are already implemented in some companies, most industrial robots are rigidly pre-programmed for repetitive, predictable tasks in controlled settings and are often time-consuming and costly to implement. They are unable to handle real-time predictions and changes in their tasks or environment and lack creativity, problem-solving, or human judgment to seamlessly navigate dynamic environments and conquer complex tasks.

With physical AI, industries can revolutionize their businesses and future-proof their product lines and revenue. By understanding how the physical world intersects with sensory data and decision-making software through physical AI, they can reprogram their robotic systems to think like humans and adapt and respond to the changing world in real time.

From animatronic robots to smart AI

Palladyne AI is no stranger to physical AI. The company has a legacy of innovation and extensive industry expertise focused on advanced robotics systems and AI-driven transformation.

In our first 20 years as Sarcos, we concentrated on developing complex hardware robotics systems, working with humanoid robots and defense applications. If you have taken a spin on the Pirates of the Caribbean or Jurassic Park rides at Disney or Universal Studios theme parks, the animatronic robots are in action as swashbuckling pirates and lumbering dinosaurs. The fountain show at the Las Vegas Bellagio hotel is also a Sarcos creation and emblematic of a variety of robotic experiences from its early decades in the industry.

In the 2000s, the company became Sarcos Robotics and continued work with the US military on human form-factor robots. Sarcos developed exoskeletons — wearable robots — that were designed to help military personnel lift hundreds of pounds without breaking a sweat. Throughout those years, the company built deeper knowledge and insights in developing the hardware and software to operate the complex robotic systems in unstructured and dynamic environments.

In 2024, Sarcos Robotics leadership made a conscious decision to pivot the business from hardware and focus solely on AI software development and rebranded the company as Palladyne AI. They realized their AI software was applicable to many robotic systems in the market beyond Palladyne AI’s hardware and they continued to develop AI software platforms to make robots smarter as an agnostic solution for multiple robotic platforms and hardware vendors.

Their two AI software solutions now focus on stationary robots and drone technology for customers in industries ranging from manufacturing to defense. Palladyne™ IQ works with industrial and collaborative robots such as those used on factory floors, and Palladyne™ Pilot works with drones and mobile robots.

Autonomy for robots

The “age of reason” has arrived for a new class of robotics. While most automated systems are preconfigured and programmed to do the same task over and over again, there is an opportunity to implement more agile manufacturing with robots through AI software that enables robotic systems to adapt, adjust, and solve problems autonomously in real time — right where the work is being performed.

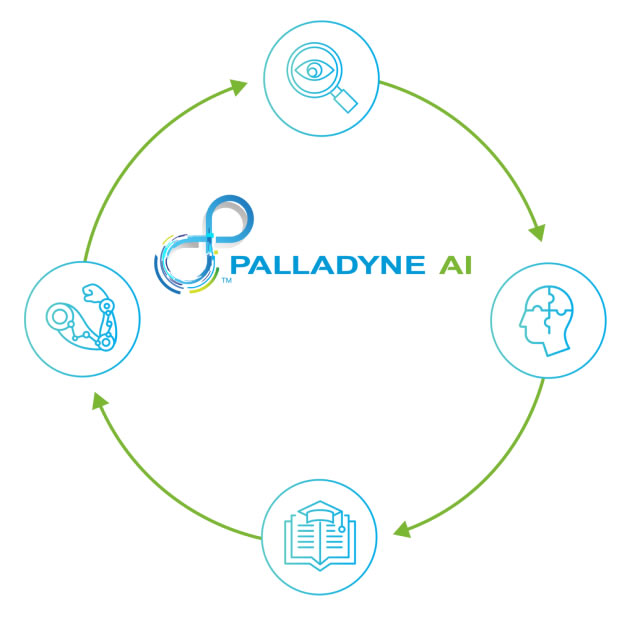

At the core of the Palladyne AI software platform lies a groundbreaking approach that we call “closed-loop autonomy.” It empowers machines to observe, learn, reason, and act with unprecedented agility, much like a human does, to get a job done. And it requires minimal training time, limited data sets, and lower power requirements.

The Palladyne IQ closed-loop autonomy software uses artificial intelligence (AI) and machine learning (ML) technologies to offer human-like reasoning capabilities for industrial robots and collaborative robots (cobots). The full-stack autonomy software enables a frontline worker to give instruction sets to the robotic systems in a simplified natural language manner or through a physical demonstration of the task to create a model of the user’s own operational steps.

The operator trains the tasks, which the robot then autonomously executes, reacts to changing circumstances, and completes tasks. Autonomously, the robot can replicate the tasks and perform new complex tasks in a fraction of the time while expanding its capabilities to perform a variety of complex tasks, while reasoning like a human without retraining or reprogramming.

Enabling robots to perceive variations or changes in the real-world environment and teaching them to adapt dynamically means tasks that have historically been too complex or costly to automate can now be autonomously addressed through robotics.

Palladyne AI enables robotic systems to run autonomously from start to finish:

- Observe the work environment

- Identify known variables and detect any variants

- Make an assessment of how to best complete the job

- Completes the task

At the source

Robots often work where cloud-based AI is a costly, highly involved solution that comes with latency issues. Because Palladyne IQ uses on-robot (“edge”) computing without connecting to the cloud, the robot can analyze, learn, and react to changing circumstances on the fly and in half the time and expenses.

Palladyne IQ software is also designed to enable low-code/no-code training of robotic systems, supporting faster deployment without the costly programming resources needed by traditional automated systems. Our systems make task programming less technical, easier and faster — making robot training accessible to a broader audience, empowering non-technical users to take over functionality previously owned by technical experts. This shift has the power to touch every user across the business.

Physical AI is transformative, but adoption takes time. We will continue to focus on solving real-world problems for our customers, building strong relationships, and letting technology prove itself. This isn’t just about building better robots; it’s about creating a future where machines and humans work together seamlessly to tackle challenges we can’t yet imagine.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Palladyne AI Corp.

Welcome to Palladyne AI, where we unleash the power of robotics with our revolutionary AI software platform for the physical world. In a world where robots are progressing toward human-like adaptability, seamlessly navigating dynamic environments and conquering complex tasks with unparalleled efficiency, Palladyne AI stands as the beacon of innovation toward that future reality. Through our cutting-edge artificial intelligence (AI) software platform, we are redefining the boundaries of robotics. Our goal is simple: Help companies with autonomy in their robotics operations by addressing key challenges of traditional robotic deployments.

Other Articles

How Autonomous AI Tackles Quality Control Costs

Addressing Challenges in Software Solutions for Robots and Physical AI

More about Palladyne AI Corp.

Featured Product