Recently, Taiga Robotics tackled one of mining’s most challenging problems, autonomous rod handling, using Teledyne IIS’s Bumblebee® X stereo camera. Their solution paired advanced robotic control software with a high-performance stereo vision system.

Bumblebee X Powers Taiga Robotics’ Mining Automation with AI-Driven Vision

Case Study from | Teledyne Vision Solutions

When automating robotics for mining, there are no second chances. Harsh weather, rough terrain, and heavy machinery create an environment where conventional technologies fail to perform, and where precision, reliability, and durability are essential.

That’s the reality Taiga Robotics faced and the challenge they set out to solve.

Founded in 2018, Taiga Robotics has evolved from its search-and-rescue roots into a specialized solution provider of robotic control and automation for mining, nuclear, and light industrial applications. Their flagship product, Synapse, is a low-code/no-code robot programming platform with built-in AI capabilities that is designed to simplify complex automation tasks in the field.

Recently, Taiga Robotics tackled one of mining’s most challenging problems, autonomous rod handling, using Teledyne IIS’s Bumblebee® X stereo camera. Their solution paired advanced robotic control software with a high-performance stereo vision system capable of seeing and understanding unstructured outdoor environments.

The Challenge: Automating Rod Handling in Rugged Terrain

In the mining sector, drill rod handling is a repetitive, high-risk task that traditionally relies on manual labor. Automating it requires more than just robotic arms, it demands precise, real-time 3D perception in environments with low texture, variable lighting, and constant vibration.

Off-the-shelf vision systems couldn’t meet the bar. Taiga needed a stereo camera with the depth accuracy, field ruggedness, and neural network compatibility to make AI-powered automation work in the field.

The Solution: Bumblebee X Stereo Camera

After evaluating multiple 3D vision options, Taiga selected Bumblebee X, a rugged, high-resolution stereo vision system purpose-built for robotics.

Taiga Robotics' field-deployed automation system features a Bumblebee X camera integrated on a robotic crane platform.

“This is an invaluable robotics camera for the mining space where the demands of the environment and the physical scale of the machines have been a challenge for us in the past.” - Ilija Jovanovic, COO, Taiga Robotics

Why Bumblebee X?

- Wide Stereo Baseline: Delivers accurate depth perception even beyond 2 meters, crucial for large-scale mining equipment.

- Rugged Design with Calibration Retention: Built to withstand sunlight, shock, and dust-heavy environments.

- 5GigE + PoE: Reliable, high-bandwidth Ethernet connectivity with long cable support, a major advantage over USB-based systems.

- RGBD Output for AI: Stereo image data feeds directly into Taiga’s AI pipeline for object recognition and pick affordance estimation.

System in Action

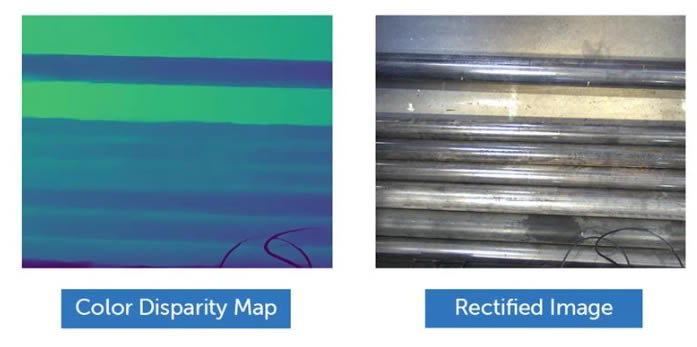

Rectified image and depth map from Bumblebee X demonstrating precise drill rod detection and depth estimation for autonomous handling.

At the heart of Taiga’s rod handling system is a robotic crane outfitted with the Bumblebee X. The stereo camera captures high-resolution image pairs, which are passed through a neural network to:

- Identify individual drill rods laid out on the ground

- Estimate grasp points and optimal pick positions

- Trigger autonomous motion planning and control for the robotic arm

The entire vision and control stack runs on a ruggedized AMD V1806 edge AI compute platform, connected to the camera via a 5-meter Ethernet cable with Power over Ethernet (PoE). Using Spinnaker SDK and a ROS-based pipeline, Taiga’s Synapse platform orchestrates the system for robust, autonomous operation. No coding is required.

The combination of Synapse and Bumblebee X has enabled Taiga Robotics to deploy field-ready, autonomous robotic systems for their mining customers. These systems reduce safety risks, boost productivity, and bring a new level of precision to large-scale industrial tasks.

By leveraging Teledyne’s stereo vision technology, Taiga Robotics has transformed one of mining’s toughest manual operations into a clear example of what AI-powered automation can achieve.

A short demo of Taiga’s vision-guided robotic system in operation.

About Bumblebee X

Building on the trusted legacy of the original Bumblebee, the Bumblebee X continues to impress with robust factory calibration retention. This reliability is backed by a powerful FPGA-based stereo processing engine and an extended working distance of up to 20 meters, making it ideal for large-scale environments. With high-resolution depth output, an IP67-rated enclosure, and support for both real-time SGBM and advanced deep learning algorithms, Bumblebee X is the next-generation stereo vision solution for industrial robotics, inspection, and autonomous navigation.

Learn more about Bumblebee X and explore Taiga Robotics solutions at www.taigarobotics.com.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Teledyne DALSA

Teledyne Vision Solutions offers the world's most comprehensive, vertically integrated portfolio of industrial and scientific imaging technology. Aligned under one umbrella, Teledyne DALSA, e2v CMOS image sensors, FLIR IIS, Lumenera, Photometrics, Princeton Instruments, Judson Technologies, Acton Optics, and Adimec form an unrivalled collective of expertise across the spectrum with decades of experience and best-in-class solutions. Together, they combine and leverage each other's strengths to provide the deepest, widest sensing and related technology portfolio in the world. Teledyne offers worldwide customer support and the technical expertise to handle the toughest tasks. Their tools, technologies, and vision solutions are built to deliver to their customers a unique and competitive advantage.

Other Articles

Real-Time, High-Resolution Stereo Vision for Industrial Robotics

The Rubik and the Robot

More about Teledyne DALSA

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product