T100 Underwater Thruster Designed for Marine Robotics

From BlueRobotics' Kickstarter:

An efficient, rugged, affordable underwater thruster to propel the future of marine robotics and ocean exploration. ($100 dollars a thruster, est delivery Nov 2014)

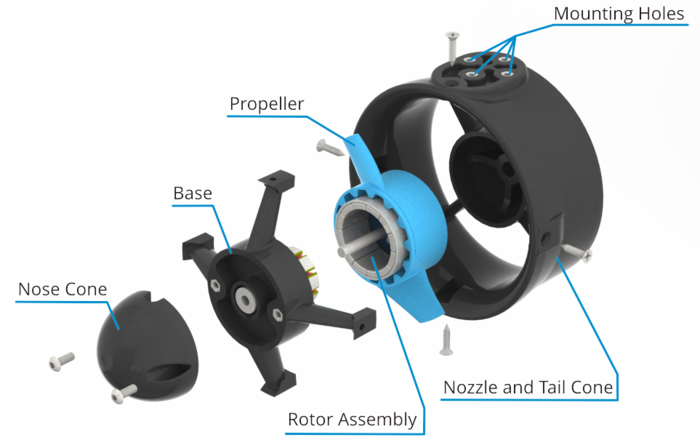

The T100 is made of high-strength, UV resistant polycarbonate injection molded plastic. The core of the motor is sealed and protected with an epoxy coating and it uses high-performance plastic bearings in place of steel bearings that rust in saltwater. Everything that isn’t plastic is either aluminum or high-quality stainless steel that doesn’t corrode.

A specially designed propeller and nozzle provides efficient, powerful thrust while active water-cooling keeps the motor cool. Unlike other thrusters, our design doesn’t have any air- or oil-filled cavities - water flows freely through all parts of the motor while it's running. That means it can go deep in the ocean and handle extreme pressures.

The thruster is easy to use: just connect the three motor wires to any brushless electronic speed controller (ESC) and you can control it with an RC radio or a microcontroller. It's usable with Arduino, ArduPilot, Raspberry Pi, BeagleBone, and many other embedded platforms... (kickstarter)

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product