DESTACO Unveils the eRDH Series Electric Parallel Gripper: The Future of Automated Handling

This latest addition to the DESTACO Robohand product line represents a significant leap forward in gripping technology, offering unparalleled precision, flexibility, and ease of use.

From Displacement to Empowerment: How Robotics Developers Can Lead the Workforce Reskilling Revolution

As automation continues to integrate into our factories, warehouses, and supply chains, the conversation around workforce transition and reskilling has become one of the most urgent and defining challenges of our time.

How AI, Robotics, and Automation Power Next Generation Pack Assembly

Successful pack assembly systems balance throughput, quality, and safety in real time. Integration matters more than buying the most sophisticated robots; it comes down to seamless software logic, modular failover paths, and smart system design.

How Is Modular Robot Design Reshaping Factory Automation?

How industrial robots work constantly adapts to increased demand and novel technologies, but it enhances automation potential the most. What is shifting and how can production engineers and electronics experts in these sectors fully leverage the benefits?

System lets robots identify an object's properties through handling

With a novel simulation method, robots can guess the weight, softness, and other physical properties of an object just by picking it up.

Shibaura Machine unveils complete robotics line automation at Automate 2025

At Automate 2025, the company will display all four models from the range: the THE400, THE600, THE800 and THE1000. The compact THE400 is ideal for fast, precise operations in assembly and inspection processes, particularly within the electronics and automotive sectors.

"Robotics is About People - Why You Need Change Management"

Success in robotics is fundamentally about people, which is why change management is crucial for any organization considering RPA implementation.

Fizyr, Cognibotics and Zivid Deliver World's Fastest Automated Bin Picking Solution

The Zivid 2+R-series camera captures true-to-reality point clouds, even when presented with shiny and transparent objects, in under 150 milliseconds ensuring it does not limit the cycle time of the Cognibotics HKM1800

A3 Releases Vision for a U.S. National Robotics Strategy

Strategy outlines key policy priorities, including establishing a central Robotics Office and Robotics Commission, to strengthen U.S. competitiveness in robotics, drive innovation, and support workforce development

NGen, Humber Polytechnic, and Festo Didactic Showcase Canadian Skills at Hannover Messe 2025

NGen, Festo Didactic and Humber Polytechnic, a leading Canadian post-secondary institution known for its career-focused, hands-on approach to education, are partnering to demonstrate the strength of Canadian mechatronics skills at Hannover Messe.

Robotic Software Market is Poised to Surpass USD 150 Billion by 2034

With businesses across industries striving to optimize operations, increase efficiency, and reduce costs, robotic software is becoming a crucial component of modern industrial and service applications.

'Eyes, hands, brains and mobility' will define robotics beyond 2025

Building on 50 years of robotics leadership, 2025 marks the beginning of a new era of AI application in industrial robotics. Launch of new ABB Robotics brand film unveils new levels of versatilty for robots to do more tasks, in more places.

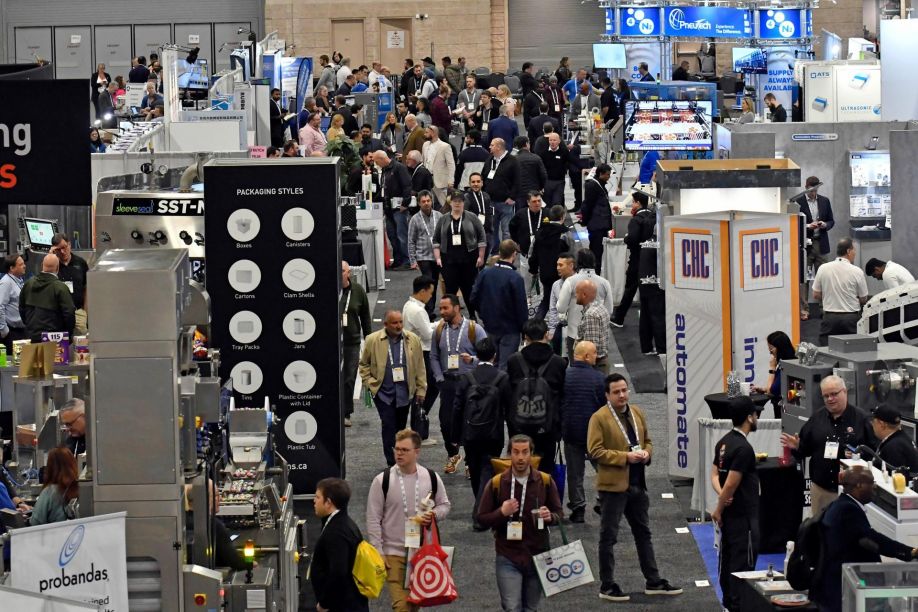

PACK EXPO Southeast 2025: The Future of Packaging & Processing Arrives in Atlanta

This brand-new regional show promises to connect industry leaders, innovators and decision-makers while showcasing cutting-edge technologies that will shape the future of manufacturing across more than 40 vertical markets.

Enterijer Mesicki and RoboDK Transform Serbian Furniture Manufacturing with FANUC Robots

Furniture manufacturer Enterijer Mesicki has created a cutting-edge robotic solution for automated furniture production using RoboDK software and FANUC technology.

Developing robotic solutions: partnering for success in micro-motion control

To turn a motion concept into reality, dedicated engineering expertise can be invaluable. Not only can motion engineering support help to improve performance and reliability, but a design partnership can also optimize commercial viability - and reduce time to market.

Records 1 to 15 of 920

Industrial Robotics - Featured Product

IP Seals for Robots

Freudenberg Sealing Technologies' IPRS (Ingress Protection Seals for Robots) provides reliable protection for robotic systems operating in harsh environments. Designed to prevent dust, moisture, chemicals, and wear from compromising performance, IPRS extends service life and reduces maintenance. The adaptive Z-shaped geometry ensures sealing integrity under continuous motion, making it ideal for high-speed automation and outdoor applications. Manufactured with high-performance elastomers such as Fluoroprene XP and EPDM, IPRS offers exceptional resistance to lubricants, cleaning agents, and extreme temperatures. This makes it the perfect solution for six-axis robots, SCARA robots, AMRs, AGVs, and cobots.

With its low-friction design and durable materials, IPRS enhances energy efficiency and operational reliability in industrial and autonomous robotics. Learn more about our IPRS Seals

.jpg)

.jpg)

.jpg)