Artificial fingertip that 'feels' wins international robotics competition

Phys.org: An open-source 3D-printed fingertip that can 'feel' in a similar way to the human sense of touch has won an international Soft Robotics competition for its contribution to soft robotics research.

Phys.org: An open-source 3D-printed fingertip that can 'feel' in a similar way to the human sense of touch has won an international Soft Robotics competition for its contribution to soft robotics research.

Pushing the boundaries of soft robotics, the open-source tactile fingertip, known as TacTip, is a 3D-printed tactile sensor that has been developed by the Tactile Robotics Team from Bristol Robotics Laboratory (BRL).

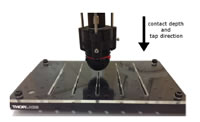

The fingertip meets the need for a cheap, robust, versatile tactile sensor to give robots an artificial sense of touch. The sensor has a unique design in which a webcam is mounted inside a 3D-printed soft fingertip to track internal pins that act like touch receptors inside our own fingertips, making it cheap to build and highly customisable. Cont'd...

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product