Sonair's ADAR 3D Ultrasonic Sensor

ADAR stands out by combining full-3D sensing via ultra-sound, strong safety credentials, cost efficiency and ease of integration. This is enabling robots to safely work in closer proximity to people and in tougher environments than many existing solutions.

From Centralized Brains to Edge Intelligence: Rethinking Compute Architectures for Autonomous Mobile Robots

Today's AMRs are navigating unpredictable warehouse aisles, adapting to real-time sensor feedback, and running machine learning inference on the fly - meaning developers can ill afford inefficient systems.

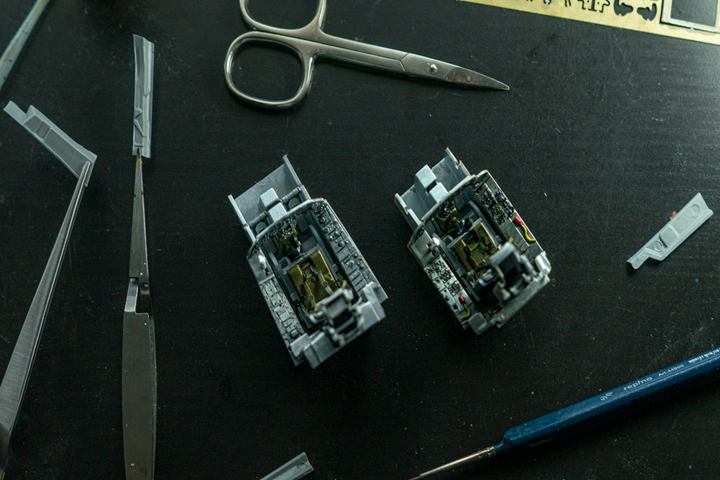

How to Choose the Right NDT Methods for Robotics Manufacturing

With so many NDT options available, the best one depends on the specific materials and functions in question. As a result, it is often most helpful to vary methods between components.

System lets robots identify an object's properties through handling

With a novel simulation method, robots can guess the weight, softness, and other physical properties of an object just by picking it up.

How Robot Sensors Are Powering a USD 5 Billion Revolution by 2032

By 2032, the projected $5 billion valuation of the robot sensor market will not only signify economic success but also mark a pivotal chapter in the evolution of robotics technology.

Mecademic robots achieve sense of touch with Bota sensors

Mecademic's plug-and-play micro-automation robots are designed for precision applications in areas such as component manufacturing. To give its robots the required sense of touch, Mecademic has focused on perfecting the use of force torque sensors from Bota Systems.

The Core of Optimizing Robotic Performance: Sensors in Warehousing

Without any external input to guide its actions or decisions, a robot would behave like a machine, performing tasks without adaptation or autonomy. Serving as the critical link between the robot and its environment, sensors enable the robot to perceive and interpret.

Understanding Force Sensors: How They Work and Measure Force

A force sensor measures mechanical forces, like a secret handshake between machines and the real world. These ingenious devices convert mechanical force into electrical signals, enabling us to measure, analyze, and interact with the physical world around us.

Robotics Applications in Manufacturing and the Sensors Used for Maximum Efficiency

Autonomous industrial robots can increase production volumes exponentially, yielding high profits. The International Trade Administration has reported that increasing robot density by a small 1% among all industries can improve productivity by 0.8%.

SIKO supports development project for autonomously operating harvesting vehicle in fruit orchards - Autonomous robot for harvesting apples

Measurement and sensor solutions from SIKO are not only found in established industrial applications, SIKO GmbH is also currently supporting an agricultural research and development project with two rotary encoders from its range for mobile machines.

Accommodating Market Volumes and Staying Competitive with Scalable Sensor Solutions

As companies continue to integrate more automation into their warehouses and DCs, the need for intelligent sensors to monitor and guide that equipment in a very safe, efficient, and productive manner will also increase.

Using ASICs to enable high-performance, cost-effective position sensors

'Position sensor' is a broad term covering a range of technologies. In this article, we consider sensors that measure rotation and linear displacement.

Trends Shaping the Automation Industry

The topic of retrofitting, i.e., the modernization of machines and systems into the digital age, is also an important trend in terms of sustainability, energy saving and resource optimization that we are also serving.

How Robotics is Transforming Manufacturing

When you sell a robot, the amount of additional required pneumatic components, sensing products, vision inspection systems and machine safety products can cost as much or more than the robot itself. Every robot sold has an exponential economic ripple effect.

Co-Learning of Task and Sensor Placement for Soft Robotics

Deep-learning technique optimizes the arrangement of sensors on a robot's body to ensure efficient operation.

Records 1 to 15 of 36

Featured Product

TM Robotics - Shibaura Machine THE SCARA range

The THE range from Shibaura Machine is an extensive line up of SCARA robots. Available in four arm lengths THE400 (400mm), THE600 (600mm) and the most recent THE800 (800mm) and THE1000 (1000mm), this range is suitable for assembly, handling, inspection and pick and place processes in varied industrial applications. The THE1000 boasts a 20kg payload capacity and an impressive 0.44 second cycle time, providing high speeds for processes with large components. In fact, the range has been recognised for as the price-to-performance leader compared to other SCARA models in its price range due to its impressive speed versus payload capacity.

Robotics and Automation - Featured Company

Servo2Go.com Ltd.

Servo2Go.com is an Online E-Store Distributor of Automation & Motion Control Systems & Components including: Servo Motors & Drives, Stepper Motors & Drives, Automation & Motion Controllers, HMIs, Positioning Systems & Actuators, Gearboxes, Couplings, Brakes, Encoders, Tachometers and Linear Displacement Transducers. Servo2Go.com is an ISO9001:2015 Registered Company.

.jpg)

.jpg)