SME, Stratasys Announce Winners of FANUC-Inspired SkillsUSA Additive Manufacturing Competition

SME and gIobal additive manufacturing leader Stratasys have announced the winners of their co-sponsored 2019 Additive Manufacturing Competition, held during the 55th annual SkillsUSA National Leadership and Skills Conference in Louisville, Kentucky, June 24-28. Six teams — three high school and three college teams — received top honors for the exceptional designs they created during the three-day contest. SME and Stratasys have collaborated on the contest for the past five years, designing the challenge to educate high school and postsecondary students about additive manufacturing technologies while providing them with real-world, hands-on experience utilizing the technology.

"Every year the participants in our SkillsUSA Additive Manufacturing Competition impress us with how much they know about the technology and how resourcefully they approach the contest challenges," said Sandra L. Bouckley, FSME, P.Eng., executive director and CEO, SME. "Additive manufacturing is an integral part of the future of manufacturing across every industry. We are proud to partner with Stratasys — and this year FANUC — on a contest that encourages students to develop their technical knowledge and hone their creative problem-solving skills — both qualities required for innovating in expanding technology sectors."

SME created the Additive Manufacturing Competition to attract and introduce the younger generation to emerging technologies that manufacturers have adopted over the past few years. With the support of Stratasys, the competition has grown from 13 teams since the contest began in 2015 to 47 teams that competed this year.

"For five years, we've partnered with SME for this incredible event — providing students with real-world experience to test the power of additive manufacturing and how it's transforming business. No other event comes close to giving high school and postsecondary students the hands-on experience required to compete in the workforce," said Gina Scala, marketing director, global education at Stratasys. "Each year, the entries get better and more innovative. These are a great batch of students today, who will turn into the industry leaders of tomorrow."

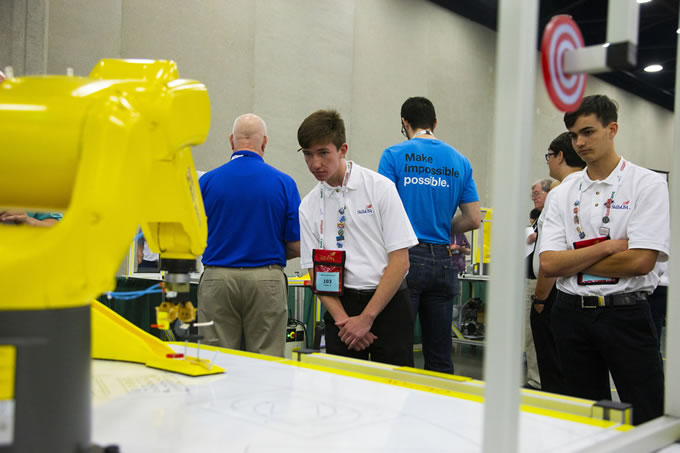

SME and Stratasys also partnered with FANUC — a provider of industry-leading robotics, CNC systems and factory automation — to develop the 2019 challenge, which required participants to design, fabricate and apply an end-of-arm tool in a simulated real-life manufacturing robotics scenario involving a full-production sedan assembly line. By the end of the challenge, participants demonstrated their ability to conceptualize, design, iterate and apply a 3D-printed tool, which, aided by a robot running a pre-installed program, repeatably placed an emblem on a target in the correct position and orientation.

"FANUC's certified robotics and automation education programs focus on the need to prepare a pipeline of workers who possess the core competencies and automation technology skills to work in high-tech manufacturing," said Paul Aiello, director of education, FANUC America. "My hope is that events like this will help inspire students to look at what manufacturing offers as great careers with growth opportunities, high wages and strong benefits packages."

In addition to the design challenge, students took Tooling U-SME's Additive Manufacturing Fundamentals Certification exam to test their knowledge of additive manufacturing. This certification is ideal for high schools and colleges as a capstone or standalone achievement to increase workforce readiness in this market.

The winning teams received gold, silver and bronze medals from SkillsUSA as well as scholarships from the SME Education Foundation (for high school participants), a one-year subscription for Tooling U-SME classes, RAPID + TCT conference passes (for postsecondary participants), Solidworks' 3D-CAD design software and a MakerBot Mini printer (gold medal winners).

More than 6,500 career and technical education students –– all SkillsUSA state contest winners –– competed in 103 different hands-on trade, technical and leadership fields during the national conference.

2019 winners of the SME/Stratasys SkillsUSA Additive Manufacturing Competition:

|

High School Teams |

College Teams |

|

Gold Medal: Hunter Donahoe, Gabe Yeoman Spring Valley High School Huntington, West Virginia |

Gold Medal: Donovan Gentles, Wyatt Brogden Butte College Oroville, California |

|

Silver Medal: Griffin Rossberg, Spencer Richardson Wasatch High School Heber City, Utah |

Silver Medal: Brandon Lund, Cody White Texas State Technical College - Waco Waco, Texas |

|

Bronze Medal: Jordan West, Justin Morrow Millard North High School Omaha, Nebraska |

Bronze Medal: Dylan Murphy, Makayla Yount Catawba Valley Community College Hickory, North Carolina |

Click here to see the devices this year's winners designed. View our video about the 2019 contest. To learn more about the SME/Stratasys SkillsUSA competition click here.

About SME

SME connects manufacturing professionals, academia and communities, sharing knowledge and resources to build inspired, educated and prosperous manufacturers and enterprises. With more than 85 years of experience and expertise in events, media, membership, training and development, and also through the SME Education Foundation, SME is committed to promoting manufacturing technology, developing a skilled workforce and attracting future generations to advance manufacturing. Learn more at sme.org, follow @SME_MFG on Twitter or facebook.com/SMEmfg.

About Stratasys

Stratasys is a global leader in additive manufacturing or 3D printing technology and is the manufacturer of FDM® and PolyJet™ 3D printers. The company's technologies are used to create prototypes, manufacturing tools, and production parts for industries, including aerospace, automotive, healthcare, consumer products and education. For 30 years, Stratasys products have helped manufacturers reduce product-development time, cost, and time-to-market, as well as reduce or eliminate tooling costs and improve product quality. The Stratasys 3D printing ecosystem of solutions and expertise includes: 3D printers, materials, software, expert services, and on-demand parts production. Online at: www.stratasys.com, http://blog.stratasys.com and LinkedIn.

About FANUC America Corporation

FANUC America provides industry-leading robotics, CNC systems, and factory automation. FANUC's innovative technologies and proven expertise help manufacturers in the Americas maximize productivity, reliability and profitability. For more information, please call: 888-FANUC-US (888-326-8287) or visit our website: https://www.fanucamerica.com/. Also, connect with us on YouTube, Twitter, Facebook, LinkedIn and Instagram.

About SkillsUSA

SkillsUSA is a nonprofit partnership of education and industry to strengthen our nation's skilled workforce. Driven by employer demand, SkillsUSA helps students develop necessary personal and workplace skills along with technical skills grounded in academics. This SkillsUSA Framework empowers every student to succeed at work and in life, while helping to close the "skills gap" in which millions of positions go unfilled. Through SkillsUSA's championships program and curricula, employers have long ensured schools are teaching relevant technical skills, and with SkillsUSA's new credentialing process, they can now assess how ready potential employees are for the job. SkillsUSA has more than 360,000 annual members nationwide in high schools, colleges and middle schools, covering over 130 trade, technical and skilled service occupations, and is recognized by the U.S. departments of Education and Labor as integral to career and technical education. For more information: www.skillsusa.org

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product