Dancing with the Light: A New Way to Make Crystals Bend by Shining Light

Generating mechanical motion in crystals using light or heat has increasingly become the focus of materials scientists. However, the conventional mechanism employed for the purpose produces slow responses and is ineffective for thick crystals. Now, in a new study, scientists from Japan report and validate a new mechanism for generating fast bending motion in thick crystals with light-induced heating, opening doors to light-driven mechanics with more versatile crystals.

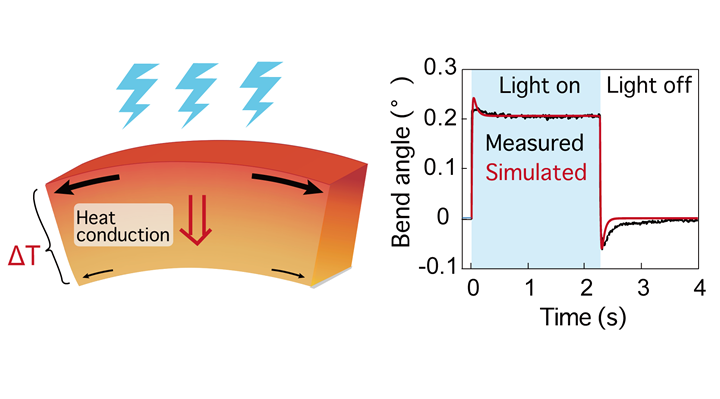

The photothermal effect enables high-speed bending motion in nearly all crystals, increasing the potential and versatility of crystals as actuation materials | Image credits: Hideko Koshima from Waseda University

The word “crystal” typically conjures up images of gemstones like diamonds in our minds. Generally associating words like “hardness” and “rigidity” with crystals, we would most likely not consider them as flexible. However, certain “molecular crystals” can bend, twist, and even jump when excited with light or heat and have garnered attention from chemists, materials scientists, and engineers alike owing to their potential applications in actuators, artificial muscles, and soft robotics.

The secret to the remarkable mechanical properties of molecular crystals lies in “photoisomerization,” a process in which a molecule takes on a different structure by absorbing light. However, several drawbacks, such as slow mechanical response and limited choice of wavelength for inducing photoisomerization, limit the applicability of molecular crystals. Moreover, only very thin crystals (up to 20 microns) can show appreciable mechanical response.

Now, in a recent study published in the Journal of the American Chemical Society, scientists from Japan have taken things to the next level by making thick crystals bend rapidly with UV light using what is called the “photothermal effect,” a phenomenon in which heat is generated by exciting materials with light. Adjunct Researcher Hideko Koshima from Waseda University, Japan, who led the study, lays out their motivation: "Last year, our team accidentally discovered that the photothermal effect causes a crystal to bend fast, but we couldn't explain why. Against this backdrop, we sought to create a new, faster bending crystal and clarify the underlying mechanism."

Scientists first exposed a thin salicylideneaniline derivative crystal, a promising mechanical crystal candidate, to UV light and obtained substantial bending within approximately 1 second. However, the bend angle dropped rapidly with increasing crystal thickness, revealing that the bending was caused by photoisomerization. Things took an interesting turn when on illuminating a thick (>40 microns) crystal with UV light, they observed an extremely rapid bending within several milliseconds, a distinct signature of the photothermal effect. Furthermore, by using a pulsed UV laser light, they could make the crystals bend at a frequency of 500 Hz (cycles/second).

The scientists next determined heat conduction in the crystal using temperature wave analysis and suggested a potential bending mechanism in which a non-steady temperature gradient in the thickness direction generated the high-speed bending. By calculating the temperature gradient numerically, they simulated the bending motion to validate the proposed mechanism.

The team is thrilled about the implications of their findings. "As the photothermal effect occurs in almost all crystals that absorb light, any light may move any crystal at high speeds. Further, the bending motion can now be simulated, providing the basis for practical applications such as in light-driven actuators. What's more, these light-activated mechanical crystals can be used to create novel soft robotic structures that ensure safe human-robot interaction,” speculates Koshima, excited.

So, is a future where a friendly and safe robot companion such as Baymax from Big Hero 6 within our grasp? The findings by Koshima's team have certainly put us one step forward in that direction.

***

Reference

Authors: Shodai Hasebe (1), Yuki Hagiwara (1), Jun Komiya (2), Meguya Ryu (3), Hiroki Fujisawa (4), Junko Morikawa (4), Tetsuro Katayama (5), Daiki Yamanaka (5), Akihiro Furube (5), Hiroyasu Sato (6), Toru Asahi (1,2,7), and Hideko Koshima (7)

Title of original paper: Photothermally Driven High-Speed Crystal Actuation and Its Simulation

Journal: Journal of the American Chemical Society

DOI: https://doi.org/10.1021/jacs.1c03588

Affiliations:

(1) Department of Advanced Science and Engineering, Waseda University

(2) Department of Nanoscience and Nanoengineering, Waseda University

(3) Research Institute for Material and Chemical Measurement, National Metrology Institute of Japan

(4) School of Materials and Chemical Technology, Tokyo Institute of Technology

(5) Department of Optical Science, Tokushima University

(6) Rigaku Corporation

(7) Research Organization for Nano and Life Innovation, Waseda University

About Waseda University

Located in the heart of Tokyo, Waseda University is a leading private research university that has long been dedicated to academic excellence, innovative research, and civic engagement at both the local and global levels since 1882. The University ranks number one in Japan in international activities, including the number of international students, with the broadest range of degree programs fully taught in English. To learn more about Waseda University, visit https://www.waseda.jp/top/en

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product