How Does the "Goods-To-Person" Method Improve Warehouse Efficiency?

The goods-to-person is an order preparation and picking method in which products are delivered directly to the picker by means of automated systems. With the rapid growth of e-commerce and recent e-grocery, fast order preparation is becoming necessary and a core competency for many companies. Traditionally, the goods-to-person method is enabled by large and complex AS/RS systems where shuttle carts, roller conveyors, and stack cranes are used for transporting items. Recently, implementing mobile robots in warehouses for automation has been increasingly popular, and the market of logistic mobile robotics attracts millions or even billions of dollars of investments every year, according to IDTechEx's report "Mobile Robotics in Logistics, Warehousing and Delivery 2022-2042". There are some forms of mobile robotic systems that can complete the "goods-to-person" operations in a more flexible, scalable, and efficient way.

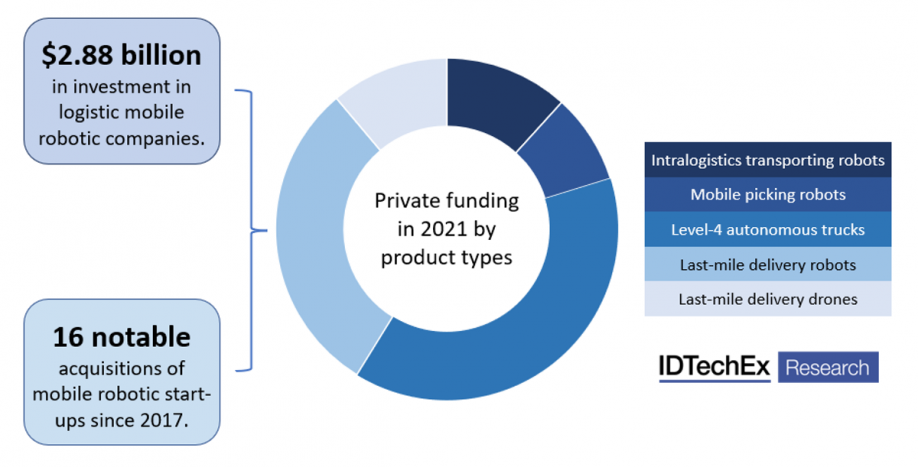

Breakdowns of private funding in the logistic mobile robotic market in 2021 by product types. Source: IDTechEx - "Mobile Robotics in Logistics, Warehousing and Delivery 2022-2042"

The most widely used mobile robots for "goods-to-person" are grid-based automated guided carts (AGCs) that follow the QR code grid laid on the ground to move shelves or pallets to pickers. The robots work in a compact storage area separated from other working zones. Human pickers only interact with robots through picking stations to pick the ordered items from shelves or pallets.

More efficiency

Less working intensity

Less cost

Lower error rate

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product