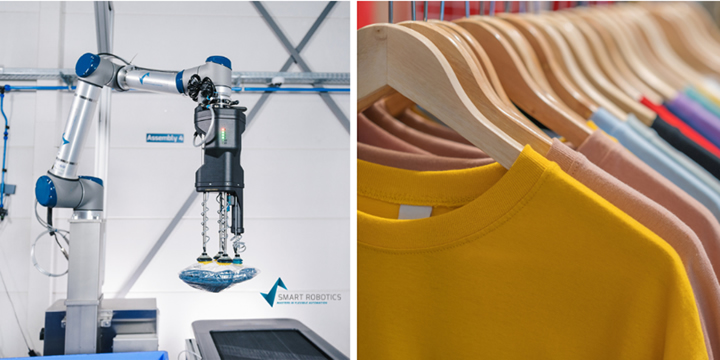

Smart Robotics announces the launch of their latest design in Warehouse Automation - the Smart Fashion Picker

Eindhoven, the Netherlands, 22 August 2022: As of today, Smart Robotics, a global leader in picking automation as a service for warehouses and logistics processes, is announcing the official launch of their latest cobot - the Smart Fashion Picker. The reliability of the cobot, and its ability to run continuously, ensures quicker return on investment – whilst answering the labour crisis in logistics and bettering the physical and mental health of warehouse employees.

The Smart Fashion Picker addresses the pain point of transformation within warehouse automation. The need arises from the notion that the warehouse sector is quite late to automation, compared to other industries, and is now looking at a rapid transition to modern processes. Transformation is greatly needed since the efficiency of piece picking in warehouses plays a key role in creating a frictionless course of the logistics to follow.

The Smart Fashion Picker’s name is derived from its function – the cobot can pick a large variety of fashion items, which are placed in protective wrapping, straight from a cart or bin. The vision sensors, motion and task planning algorithms help the cobot to calculate what to pick next, as well as how to pick and place the item accurately into the next bin, plus it can easily detect when the bin is empty or filled.

“We’re super excited to introduce this product to the wider market after successful implementation with our initial customers. It has proven to deliver steady, reliable performance with the throughput necessary to be relevant in a warehouse whilst it is able to cope with the often-changing large product ranges that are typical for the industry. This product is an important step in our master plan to reduce repetitive and harmful work in warehouses around the globe.” - Johan Jardenvall, CEO of Smart Robotics.

Picking items in warehouses is a repetitive process that’s hard-wearing on the people who manually pick and place items. Automating thus enables warehouse employees to tend to the robotised systems, rather than wearing themselves out by picking and sorting items.

The cobot is capable of handling items at a pace that matches human pickers, requiring very little oversight. The system ensures reliable and uninterrupted operation and doesn't require any special training from its operators. Not to mention, it can safely be managed by people of all skill levels.

In addition, the Smart Fashion Picker is smarter in its ability to adapt with changing circumstances around it, such as changes in assortment, how the cobot interacts with people moving around it, etc. As such, the Smart Fashion Picker is capable of working in the real world of warehouses, instead of a predefined, coded, environment.

Smart Robotics has been developing picking applications based on cobots, since 2017, and is confident that the Smart Fashion Picker will help ensure more reliable capacity in highly demanding logistics. This launch is a great achievement in Smart Robotics’ continuity of improving their cobot designs. The Smart Fashion Picker is but one of the many improvements Smart Robotics has in the pipeline to make warehouse automation more versatile and dynamic in a highly performant logistics industry.

About Smart Robotics

Smart Robotics offers picking automation as a service for production- and logistics processes around the globe. Smart Robotics is a world-leading company that enables their customers to improve quality of work in fulfilment centres and to scale their business. The company’s innovative and reliable cobots can help to overcome the ever-growing labour shortages and scale up production by taking over repetitive and physically straining tasks, such as palletizing, picking and placing of items. Thanks to the company’s advanced AI software, accuracy and operational efficiency is improved - whilst the cobot picking arms safely cooperates with warehouse employees.

*Cobot

A “cobot” is a smaller, safe to be around, robot. The term “cobot” is short for “collaborative robot”. In warehouses, cobots don’t need to be fenced off, or be isolated from human contact - as with traditional industrial machinery, and people can directly interact with the cobot. Cobots are designed with the intention to engage in a shared space, integrating in environments where robots and people operate in close proximity.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product