How Collaborative Robots Improve Flexibility, Safety, and ROI

When we design cobot palletizing systems, we're often solving two different problems: limited floor space and the need to shift operations between lines throughout the day.

The Human-Machine Symbiosis: Why Industry 5.0 is the Future of Manufacturing

A new paradigm is emerging—Industry 5.0—that offers a powerful solution, not by replacing the human workforce, but by augmenting it through a revolutionary collaboration with machines.

The Collaborative Revolution: How AI, Digital Twins, and Cobots are Reshaping Manufacturing & Industry

The manufacturing and logistics industries are undergoing a significant transformation due to the integration of AI, digital twins, and collaborative robots. AI acts as the intelligent core, optimizing cobot control, predictive maintenance, and supply chain management.

The Human + Robot Workforce: How Collaborative Robotics Are Solving the Labor Crisis

Collaborative robotics like person-to-goods or 'pick assist' AMRs are intelligently designed to work with people, not replace them. Adoption of AMRs for automated order fulfillment is turning this challenge into a competitive advantage.

Beyond Protection: How Advanced Sealing Solutions Are Enhancing Robotic Performance

Sealing technology plays a decisive role in ensuring performance stability, reducing friction, and protecting components from environmental influences. High-performance seals are essential for extending the life of robotic joints, actuators, and automated systems.

Artly AI Presents Natural Robotic Hand Upgrade for Barista Bot at Nvidia GTC 2025

Barista Bot can already craft 28 hot and iced beverages by replicating the artist's movements. The new robotic hand upgrade improves the current gripper system in replicating human motion to better manipulate everyday objects.

Enterijer Mesicki and RoboDK Transform Serbian Furniture Manufacturing with FANUC Robots

Furniture manufacturer Enterijer Mesicki has created a cutting-edge robotic solution for automated furniture production using RoboDK software and FANUC technology.

Examining the Growing Presence of Cobots in Agriculture Operations: 7 Insights

Agricultural automation is still a relatively new field, so understanding how to use it effectively is evolving as the sector matures. Here are seven insights worth taking away from the rise of agricultural cobots.

Universal Robots unveils its AI Accelerator, enabling a new wave of AI-powered cobot innovations

Designed for commercial and research applications, the UR AI Accelerator provides developers with an extensible platform to build applications, accelerate research and reduce time to market of AI products.

Employees say that robotics and AI offer safety, productivity, and career benefits in new MIT Study

One of the key trends in the data that shows promise is that 60% of employees globally who have interacted with robotics and AI expect positive impacts on their safety, career development, and productivity.

ABB launches groundbreaking Ultra Accuracy for GoFa cobots

Ultra Accuracy feature increases accuracy by ten times in GoFa™ cobot family vs. other cobots on the market. Path accuracy of 0.03 mm supports accurate production in electronics, automotive, aerospace, and metal fabrication industries

AI and Cobots: The Dynamic Duo Changing Manufacturing

These seven use cases are just a sample of the ways manufacturers can improve their cobot operations with AI. Capitalizing on this potential today will help companies maximize their cobot ROIs and ensure success well into the future.

World's First Window Cleaning Robot Reports to New York City Skyscraper Transforming the Industry Globally

Ozmo's arrival ushers in a new era for the $40B window-cleaning industry, offering a solution to a global shortage of manual window cleaners that will create new jobs and, when fully autonomous, keep humans out of harm's way with advanced technology.

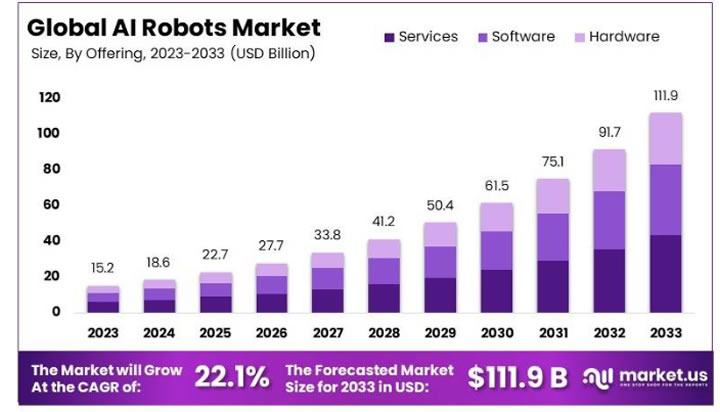

AI Robots : Transforming Industries with Smart Robotic Solutions

The demand for AI robots is driven by the need for automation and efficient data management across various industries. In manufacturing, AI robots are used to automate complex assembly lines, reducing labor costs and increasing productivity.

If You're Struggling With Production Inefficiencies, Cobots Might Help

A collaborative approach to automation offers solutions where older methods have fallen short. Manufacturers who have struggled to achieve desired results from conventional robotics should consider how cobots can help them strike an ideal balance.

Records 1 to 15 of 100

Featured Product

IP Seals for Robots

Freudenberg Sealing Technologies' IPRS (Ingress Protection Seals for Robots) provides reliable protection for robotic systems operating in harsh environments. Designed to prevent dust, moisture, chemicals, and wear from compromising performance, IPRS extends service life and reduces maintenance. The adaptive Z-shaped geometry ensures sealing integrity under continuous motion, making it ideal for high-speed automation and outdoor applications. Manufactured with high-performance elastomers such as Fluoroprene XP and EPDM, IPRS offers exceptional resistance to lubricants, cleaning agents, and extreme temperatures. This makes it the perfect solution for six-axis robots, SCARA robots, AMRs, AGVs, and cobots.

With its low-friction design and durable materials, IPRS enhances energy efficiency and operational reliability in industrial and autonomous robotics. Learn more about our IPRS Seals

Robotics and Automation - Featured Company

Electrocraft Inc.

ElectroCraft, Inc. is a global provider of dependable, application-engineered fractional-horsepower motor and motion products. Our products are found in thousands of different applications within industrial, commercial, and consumer product markets. While ElectroCraft provides a wide array of standard products with many configurable options, we have built our brand on custom OEM solutions that meet the precise performance, cost and quality our customers require.

.jpg)

.jpg)

.jpg)