Collaborating with AI and Robots - Busting Common Myths

Artificial intelligence (AI) and robotics are a growing conversation across every industry, specifically around how they can streamline processes and practices. The number of AI companies in the UK has increased by 688% over the past decade and while the advancements in this technology are exciting for many, there have been myths that have instilled worry in many workers over the security of their jobs.

These technologies will inevitably make jobs significantly easier and shouldn’t be feared, which is why this article will bust three of the biggest and most common myths around AI and robotics.

Myth 1: “AI and robots will replace humans and take every job.”

Computers that learn might seem like they’re straight out of science fiction, but the reality is far from what you’ve read or seen in films and TV. A survey by Public First even found that many believe that AI could make them redundant from their jobs, with 64% of respondents stating they think AI will somewhat or significantly increase unemployment.

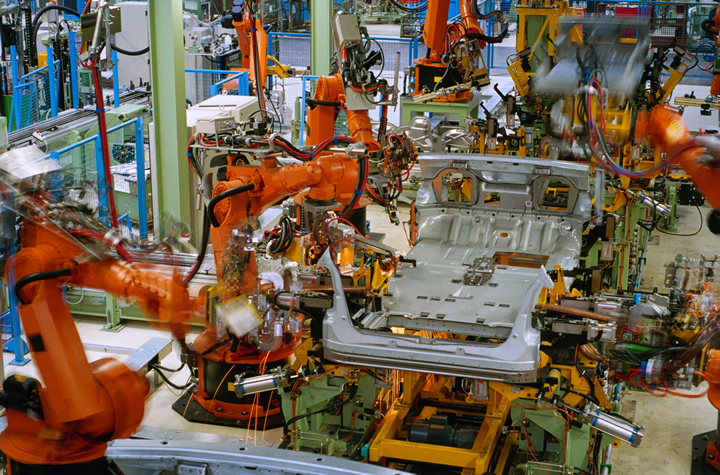

AI and robots have and will continue to change how processes are conducted, but they require human interaction to work efficiently. This means that rather than losing your position, you’re more likely to receive training on how to properly programme and interact with the new technology.

These technologies will not just streamline processes with their introduction, but they’re designed to relieve some of the heavy lifting of many roles. AI can be used for admin tasks where huge amounts of data must be analysed to produce forecasts of the future, while robots can be used for literal heavy lifting and more precise tasks that human hands may be too shaky for, removing the need for human interaction. AI can also identify patterns and predict potential workplace hazards.

Myth 2: “This technology is too expensive.”

There is some truth to this myth, but only in the sense that investing in any modern technology is going to require some budget being afforded to it. And as these technologies become more necessary for your processes, spending is likely to keep increasing.

In fact, a report by Capital Economics for the Department for Digital, Culture, Media, and Sport (DCMS) found that spending on AI tech from 432,000 UK companies who have already adopted AI reached £16.7 billion. This was broken down into an average spend of £9,500 per small business, £380,000 per medium business, and £1.6 million per large business.

As they’ve become more common across many industries, that has caused an increase in demand. Not only has this made them more accessible, but it has also brought the price down. This could further encourage businesses to invest and allow for more budget towards integrating these technologies.

Plus, with Capital Economics forecasting that spending on this technology could increase to between £27.2 billion and £35.6 billion by 2025, these technologies could become more economically accessible.

Myth 3: “Robots don’t have adequate safety features for collaboration.”

This myth partly feeds back into the ideas of robots rising up and taking over, as well as anxieties toward unknown technology. Robots are designed to assist humans and make processes simplified and, in many cases, much safer.

Laser cladding is an important process in many industries and by removing the human element with robots, it could make it much safer. Cladding requires a lot of precise and repetitive movements to assure it’s done well, and using robots could mean reduced operator dangers.

Sources

https://www.forbes.com/uk/advisor/business/software/uk-artificial-intelligence-ai-statistics-2023/

https://www.welding-alloys.com/services/engineered-wear-services/application-methods/laser-pta/

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product