Maximizing the Value of Collaborative Robots

As we will discuss in this article, cobots can add tremendous value to your operations, but you should be sure to pay attention to risk assessments and safeguarding requirements.

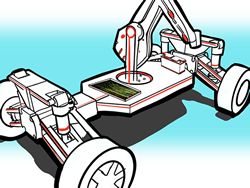

What is a Cobot? Bridging the Gap Between Robots and Humans

Optical components play a key role in the optimal performance of today's cobots, allowing them to see and respond to their environment in real-time and ensuring that they operate safely and effectively.

The Next Generation of Robots

We are moving to a world where robots need to make intelligent decisions about what to do based on what they see. Hence the need for machine learning, vision and AI.

How Are Cobots Disrupting Automotive Manufacturing?

Cobots are creating a disruption in automotive manufacturing, offering a number of benefits to businesses. How and why are these cobots being used, and what will their long-term impact be?

Standards, Guidelines & Industry Best Practices for Industrial & Collaborative Robots

The robotics industry is undergoing a significant transformation. There is a need to learn from the past, as multiple times, robots failed to behave as expected because of mechanical failure, power disruption, software issues, and environmental factors.

MakinaRocks, Hyundai Robotics sign MOU to 'advance AI-based industrial robot arm anomaly detection'

"As an increasing number of customers request AI-integrated robots, an AI-based analysis platform for robot functions is an indispensable necessity. We plan to expand our userbase with robots that can autonomously predict failures and perform quality management."

Perceptions of Collaborative Robotics Post, COVID-19, Q&A with Productive Robotics

The benefits of collaborative robots have not changed. As we come out of this, businesses will seek ways to improve their production as they always have, and cobots provide excellent solutions to these challenges.

The Center for Robotics and Biosystems at Northwestern

We are working toward the intimate physical integration of humans and robots. One example is robots that assist humans in collaborative physical tasks, like manipulating heavy objects in a warehouse.

Pick, Purchase and Program Your First Industrial Robot

Robots aren't always given a favorable representation in pop culture. In Stanley Kubrick's 2001: A Space Odyssey (1968), homicidal supercomputer HAL 9000 demonstrates how a robot could conspire against its human colleagues.

Maintenance Free UR Cobots Operate Continuously in Harsh Environment

Aircraft Tooling, a Texas-based repair center for the aviation industry, was surprised to find that Universal Robots could withstand the high temperatures and harsh environment while performing metal powder and plasma spray processes. The UR "cobots" have now been in operation for three years without breakdown or service requirements.

FT-Produktion Boosts Output Capacity Without Adding Personnel by Employing Combination of Collaborative Robots and Robot Grippers

"We chose a combination of solutions from OnRobot, Universal Robots, and EasyRobotics because they are easy to program, and the investment will pay for itself in just nine months. It's one of the best business decisions we've ever made."

The Collaborative Robot Market Will Exceed US$11 Billion by 2030, Representing 29% of the Total Industrial Robot Market

"The hardware innovation is still trailing behind, and most of the value related to cobots does not come from collaboration. It comes through ease-of-use, re-programmability, lower total cost compared to industrial systems, and re-deployability.

Smart Production Lines in Automotive Industry Use Cobots

Much like other industries, the automotive industry is changing. With the increase in the variety of vehicle models, variants, and derivatives being produced and the shorter product life cycles in the automotive industry.

New Collaborative Robot Vacuum Tool

The NEW Collaborative Robot Vacuum Tool (CRVT) from Bimba adds unparalleled flexibility to your collaborative robot. The standard CRVT is highly configurable to meet your application needs, but simple to install and operate.

Easy Programming of Cobots

Learning without programming means anyone can teach OB7 to do hundreds of complex automation jobs quickly. The operator simply shows OB7 how to do the job by physically moving the cobot through the steps, and it learns and remembers.

Records 1 to 15 of 106

Featured Product

Helios™2 Ray Time-of-Flight Camera Designed for Unmatched Performance in Outdoor Lighting Conditions

The Helios2 Ray camera is powered by Sony's DepthSense IMX556PLR ToF image sensor and is specifically engineered for exceptional performance in challenging outdoor lighting environments. Equipped with 940nm VCSEL laser diodes, the Helios2 Ray generates real-time 3D point clouds, even in direct sunlight, making it suitable for a wide range of outdoor applications. The Helios2 Ray offers the same IP67 and Factory Tough™ design as the standard Helios2 camera featuring a 640 x 480 depth resolution at distances of up to 8.3 meters and a frame rate of 30 fps.

.jpg)