Micro drives gives humanoid service robots human traits.

Contributed by | MICROMO

Since time immemorial,people have dreamed of creating artificial human beings. Nowadays,modern technology is capable of realizing this dream in the form of the humanoid robot. Even if there is still a considerable amount of development work necessary, every project has to take those first steps. As an initial stage in this process, a humanoid service robot that works autonomously already offers a wide range of benefits. Apart from the interaction of the many components used, the main challenge is the power supply and the space required for the various parts. Micro drives represent an ideal solution for resolving these two key issues. Their considerable power density,combined with high efficiency and minimal space requirement, improves the power-to-weight ratio and allows the robot to operate for long periods without having to recharge batteries.

The more human-like a robot should be,the more sophisticated the mechatronic engineering input necessary. Particularly in sectors requiring "human social behaviors",e.g. for service functions or providing information in places such as museums, airports or hospitals, sophisticated technology for robot construction is a must. For many years, the Barcelona based company Pal Robotics S.L. has been working on the construction of humanoid robots for special applications. Non-verbal communication, i.e. body language, also plays an important role in increasing the acceptance of humanoid robots. In order to accommodate as many functions as possible in the predefined robot body,the robotics experts have been working with Schönaich-based micro drive specialist FAULHABER. The outcome has been a robot model that most definitely exhibits human traits and is capable of emphasizing certain statements by means of "body language".

Sensors and a touch screen allow the robot to get its bearings and communicate

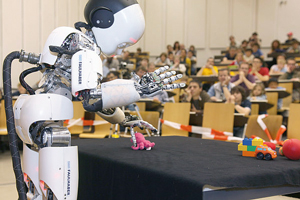

Service robots for practical applications. Humanoid robots intended to perform everyday functions have to satisfy certain conditions. The developers wanted to integrate capabilities such as information output, minor transport tasks and service functions into the new REEM robots. This resulted in a robot height of 1.65 m, so that it can communicate with humans at eye level. It was also important that the robot should not be excessively heavy, although there was a need for a low center of gravity and space to house the necessary batteries. The current robot model weighs around 90 kg, sufficient for one set of batteries allowing eight hours of autonomous operation. In addition to its unladen weight, this service robot can also carry up to 30 kg effective load on its lower loading platform. Each arm can move up to 3 kg independently. In this case, wheels located in the base of the robot ensure effective locomotion. On the one hand, this ensures minimal power consumption and quiet running, while on the other the design provides sufficient mobility for the planned application of up to 4 km/h. As well as a touch screen for the various programmable applications, the REEM is also equipped with microphone, stereo-camera, laser and ultrasound sensors,accelerometers and gyroscopes. These devices enable the robot to identify its current position in the room, move around autonomously in its area of work and avoid sudden obstacles or people walking across its path.Two DC micro drives in the robot's neck and waist provide the necessary expressiveness.Thanks to their compact dimensions,the drives can be readily used even in these two "constricted" areas.The small actuators can move head and torso independently of one another and allow them to assume different postures.This enables the robot to imitate human traits using body language suited to there situation.

Micro drives offer flexibility

Micro drives do not just replicate larger motors.Because of the physics involved they often offer better dynamics, higher output or greater efficiency than you would expect as a result of a mere reduction in size.In practice, this means that frequent heavy load capability is possible without affecting service life. This proves particularly advantageous when it comes to executing the less frequent but temporary actions necessary to mimic specific gestures. As well as these features typical of all micro motors, the various models come with further benefits depending on the application in hand. Stepper motors offer accurate positioning without additional encoders thanks to a defined step width per control pulse. Brushless drives run even at minimal supply voltages and are thus ideal for autonomous,battery-backed systems that are designed not to fail immediately in the event of a voltage drop.

Electronically commutated DC motors represent the best option for long service life and maximum dynamics.Intelligent motion controllers can control the drive in four-quadrant operation and reduce the load on the robot controller. By means of different gear motor combinations,all miniature devices can be set to an application-specific speed or the required out put torque. The fact that micro motors have for a long time already been in use in "robotized"aids such as motor-powered hand and leg prostheses shows that they meet the most stringent requirements not just for human robotics.The range of applications for modern micro drives is very varied, with a wide range of designs available depending on application.In itself, however, this does not yet guarantee universal use under all circumstances. This is where the system concept comes into play. It is the extensive range of accessories, from control modules such as motion controllers, encoders,bus connections, various gear heads and ultimately the adapted, flexible control electronics that make micro drives the ideal mechanical "muscle" in robot manufacture.

To learn more about this robot visit Pal Robotics S. L. , Barcelona, Spain.

About MICROMO

About MICROMO

For over 50 years, MICROMO has provided the highest quality, custom micro motion solutions for markets such as medical, aerospace, defense and robotics in North America. Decades ago in Germany, it all started with the FAULHABER coil, the landmark invention by Dr.Fritz Faulhaber. The self-supporting, ironless rotor coil design paved way for a new industry that produces millions of motors today.

A member of the FAULHABER Group, MICROMO brings together the widest range of high quality, high performance linear and rotary micro motion solutions, decades of micro motion expertise based on dc micro motor technology and complete, full service design, sourcing and manufacturing capability on a global basis to deliver benchmark motion solutions.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

FAULHABER MICROMO

Since 1961, FAULHABER MICROMO has partnered with OEMs to deliver high precision, high performance, custom micro motion system solutions to markets such as medical, robotics and automation in North America. FAULHABER MICROMO's tradition of innovation started decades ago in Germany. The groundbreaking invention of the FAULHABER coreless winding started it all for a market that produces millions of motors today. How can the FAULHABER MICROMO team help you deliver your next innovation to market first? Learn more about MICROMO's solutions for the most demanding applications, our diverse motion products and technologies, online ordering, Engineering and R&D teams, Clean Room Assembly, Machining Center and other services at our Clearwater, FL facility at https://www.faulhaber.com.

Other Articles

Walking naturally with artificial foot

Testing drive systems virtually - Simulink library for development and digital twin.

At least 60 million strokes

More about FAULHABER MICROMO

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product