Electrospinning can be used to produce advanced materials that otherwise would not be possible to make.

Electrospinning NanoFibers

Adam Karcz | NEI Corporation

Can you describe what electrospinning is and the general process?

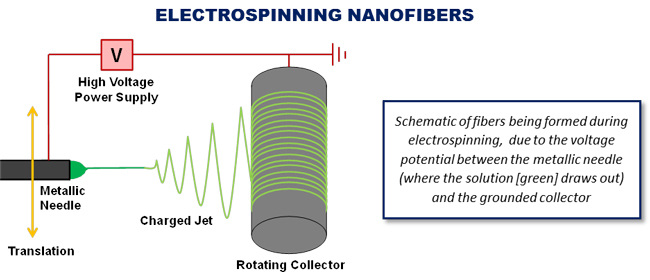

Electrospinning is a technique for producing very small diameter fibers, typically 1/10th to 1/100th the width of human hair. Electrospun fibers are usually 200 to 2000 nanometers in diameter. In the electrospinning process, a high voltage differential is applied between an emitter – where a polymer solution ejects from – and a collector (usually a metal plate or drum). The polymer solution, which contains a low boiling point solvent, is pumped into the emitter and forms a droplet at the tip. The high voltage potential draws the droplet out of the emitter in a whipping motion, elongating into a thin continuous fiber which quickly dries out.

What are the advantages of electrospinning?

Electrospinning can be used to produce advanced materials that otherwise would not be possible to make.

There are three important advantages that it offers. With electrospinning, you can: (i) produce continuous, high surface area nanofibers; (ii) form fibers with unique microstructures, such as core-sheath fibers; and (iii) incorporate nanoparticles, including carbon nanotubes (CNTs) and ceramics.

What materials can be electrospun?

Electrospinning is typically carried out using a dissolved polymer. This polymer can contain dispersed nanoparticles, such as CNTs, in order to improve its mechanical or electrical properties. By using a polymer precursor, it is also possible to fabricate ceramic or metal fibers by calcining or annealing the electrospun precursor fibers.

What can one do with microfibers and nanofibers produced by electrospinning?

These nanofibers and microfibers can be used to produce new materials, such as fiber composites, where one can introduce microfibers and nanofibers into the composite to impart capabilities not otherwise attainable, such as increased strength and conductivity. Potential applications include energy storage, such as lithium ion battery electrolytes; structural reinforcement, such as lightweight compressed natural gas (CNG) storage on both land and for transport, exteriors of automobiles and airplanes, and blades of wind mills.

You mentioned core-sheath fibers. Can you describe these in more detail and what you can do with them?

Core-sheath fibers can be thought of in a similar manner to coaxial cables. In coaxial cables, you have a metal wire which is protected by an insulating polymer. In a similar way, the core-sheath fibers will typically contain a material on the inside which needs protection, such as a metal to protect from oxidation or possibly a liquid which needs encapsulation. The sheath will provide a barrier for the core and perhaps provide some other benefits such as improved conductivity. Effectively, core-sheath fibers offer the capability to create a new morphology or microstructure in the fibers, as opposed to using a homogeneous fiber.

How can NEI Corporation help me with regard to electrospinning?

NEI can provide prototyping services on our state-of-the-art electrospinning system and develop new materials and new material morphologies. NEI’s full service R&D includes fabrication of novel materials, characterization, and testing based upon industry standards. Please see our brochure for additional information.

Please tell us a bit more about NEI Corporation --- who are you and what do you do?

NEI Corporation is an applications driven company that utilizes nanotechnology to develop and produce advanced materials. The company’s core competencies are in synthesizing nanoscale materials and prototyping products that incorporate the advanced materials. Founded in 1997, we manufacture and sell advanced materials products, provide materials development services, and perform contract-based R&D for public and private entities. NEI has built a strong manufacturing and R&D infrastructure that enables rapid transition of concepts to products. NEI’s products are sold under the registered trademark: NANOMYTE®.

Are there other Advanced Materials or processes in the works that you would like to talk about?

NEI specializes in advanced polymer-based coatings which provide protection for metal, wood, and polymer surfaces. These include abrasion resistant hardcoats, anticorrosion paints and coatings, self-healing nanocomposites coatings, and superhydrophobic coatings.

We also offer high performance battery materials in the form of cathode and anode materials for use in lithium-ion batteries. We produce battery materials through our scalable and economical solid state synthesis process, which is adaptable to different materials compositions and particle morphologies.

Additionally, we have a variety of nanomaterial products available, such as heat transfer fluids and sorbents for mercury removal in water and flue gas.

How important are advanced materials to the future and what can we expect to see evolve over the next 5 or 10 years?

Advanced materials will be critical in the future as conventional materials have inadequate properties to deal with evolving demands of increasing performance. These materials can be tailored to specific applications that require unique attributes, such as the capability to regenerate their structure as in the case of shape memory alloys and self-healing polymers. Others can achieve high durability while maintaining low weight compared to traditional metals or ceramics, which has popularized the use of carbon fiber-reinforced composites and biomimetic coatings. Typical advantages that advanced materials bring include improved fuel efficiency due to lighter weight, reduced emissions from environmental contaminants and pollutants, and superior performance in different materials applications including computing, energy storage, and structural reinforcements.

About NEI Corporation

NEI Corporation is an applications driven company that utilizes nanotechnology to develop and produce advanced materials. The company’s core competencies are in synthesizing nanoscale materials and prototyping products that incorporate the advanced materials. Founded in 1997, we manufacture and sell advanced materials products, provide materials development services, and perform contract-based R&D for public and private entities. NEI has built a strong manufacturing and R&D infrastructure that enables rapid transition of concepts to products.

NEI Corporation is an applications driven company that utilizes nanotechnology to develop and produce advanced materials. The company’s core competencies are in synthesizing nanoscale materials and prototyping products that incorporate the advanced materials. Founded in 1997, we manufacture and sell advanced materials products, provide materials development services, and perform contract-based R&D for public and private entities. NEI has built a strong manufacturing and R&D infrastructure that enables rapid transition of concepts to products.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product