We call our robots entry level for a very good reason. People can get started so easily with our robots. They are not the best robot arms on the planet but they are affordable and incredibly easy to use.

Interview with David Sands, ST Robotics International

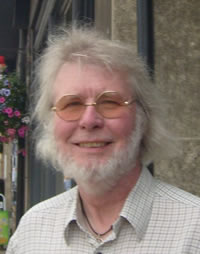

David Sands | ST Robotics International

Tell us a bit about ST Robotics, what inspired you to get it started and how the business was started?

What are your main markets served?

That is always a difficult question to answer. If you asked a laptop manufacturer the same question they would probably have the same difficulty. But broadly the markets fall into 3 cateogories: light industrial automation i.e. manufacturing, R&D and product testing - usually routine testing or sample handling, educational. ST arms are not aimed at education but seem to be very popular as they are, after all, real industrial robots albeit bench top ones.

Since you started ST Robotics what has been the biggest change you have noticed within the industry?

When I started it was a statistic that 98% of all industrial robots were in the auto industry. So the remaining 90 odd industries were using only 2% of the robots. But over the 20 years all sorts of small companies are now using robots. You might have expected me to comment on changes in the technology but actually it's not that impressive. Robots are more accurate, safer, more intelligent but basically follow George Devol's original concepts.

Why do you think ST Robotics has been successful?

A number of factors. One is unlimited unconditional 24/7 technical support. There is nothing worse than being stuck on a problem and not being able to get help until the next day or having to pay for support as is so often the case. Having experienced it so often I was determined our customers would not face the same barriers. The second is the software. When the Cyber robots were first launched they were programmed in BASIC. The designer moved on and left me with the tech support. There were so many bugs it was a nightmare and I had calls every day with problems. That is when I wrote the first RoboForth. After that when I had a customer with a software difficulty I just mailed them the Roboforth disk and never heard from them again. To this day the software is the greatest strength. It is so easy to use. People who have never programmed anything before can get to grips with my software in minutes.

What can ST Robotics contribute to the Scientific and Industrial communities?

We call our robots entry level for a very good reason. People can get started so easily with our robots. They are not the best robot arms on the planet but they are affordable and incredibly easy to use. At the same time they are capable of really complex tasks, logically, often way beyond the capabilities of the big industrial arms. So we are able to offer robotic solutions that actually can not be offered by the big name industrial robots.

What are some of the problems you have encountered along the way?

One main problem has been fluctuation in demand. For example demand was very low during the fiscal cliff while right now it exceeds our production capacity. It makes it very difficult to plan when lead times for the machining and components is 2 months.

Where do you see ST Robotics and Robotics in general 5 or 10 years down the road?

The robot arm on its own is not enough. One of the things we have done is design accessories, like electric grippers, tool changers and the Bluetooth teach console. This will have to continue as customers present new applications and new problems. So over time we will have better robots and more accessories. As for robotics in general, of course this is a very wide field. Robot arms will continue to be adopted but the other thing you will see is huge growth in autonomous drones. We don't have the capacity to get involved in that - too busy making robot arms - but expect to see that become a huge field with a whole lot of new problems like intrusion and privacy issues, people shooting them down and so on.

David Sands

David started out in industrial automation and instrumentation. In the 80s David started the company Cyber Robotics making and selling educational robots. He saw a need for something more professional yet lighter and less expensive than the big robots being used in the auto industry and started Sands Technology, later trading as ST Robotics. The major creative step for David was writing the robot language RoboForth.

About ST Robotics

ST Robotics provides professional but affordable, easy-to-use, ready-to-go boxed robots. ST aims to provide robots that are easy to set up and use, easily programmed by any individual regardless of experience, fast, accurate and reliable, and easily affordable by any industry small and large, testing and R&D departments, and laboratories.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product