Recent servo motors are equipped with the encoder of 20 bits (1,048,576 steps) which has a very fine resolution. Because of this, errors due to the encoder installation accuracy have a huge effect on stopping accuracy.

Everything You Need to Know About Stepper Motors

Contributed by | Orientalmotor

Stepper motors are often misconceived as the lesser of servo motors, but as a matter of fact, they are highly reliable just like servo motors. The motor operates by accurately synchronizing with the pulse signal output from the controller to the driver, achieving highly accurate positioning and speed control. Stepper motors feature high torque and low vibration at low-speeds, ideal for applications requiring quick positioning in short distance.

Everything You Need to Know About Stepper Motors

"Stepper motors? Servo motors must have better performance." This is a typical response when being asked about stepper motors. Obviously there is a major misconception about stepper motors. In fact, stepper motors have been used in various types of applications such as advanced equipment and accessible automated instruments. The reasons why stepper motors have been continuously chosen are explained in this article, from a different standpoint of technical aspects.

New 0.72° Stepper Motor and Driver Packages RK II Series

The new RK II Series consists of a high efficiency 0.72° stepper motor and digitally controlled driver. The attractive list price starts from $391.85, including a cable.

Some readers may say that they have never seen a stepper motor before. Stepper motors have been used in many applications and fields as the power source for drive systems requiring high accuracy control, such as factory automation (FA), manufacturing equipment for semiconductor, FPD and solar panel, medical devices, analytical instruments, precision stage, financial systems, food packaging machines, and aperture diaphragm adjustments for cameras.

In the following chapters, the reasons why stepper motors have been used in various types of applications and fields are explained.

Why do you use a stepper motor?

Easy to use: 34%

Inexpensive: 17%

Simple operations:16%

No need for tuning: 12%

Other: 21%

*# of questionees: 258 (multiple answers allowed)/ researched by Oriental Motor

Key Points: Ease-of-Use, Simple Operations and Low Cost

According to the survey of stepper motors users, many favor stepper motors for their "ease-of-use," "simple operations", and "low cost" derived from the structure and system configuration. It makes sense that many users find such positive aspects in stepper motors, thanks to the simple structure and system configuration.

However, some readers may be skeptical about the actual performance of the motor in terms of its accuracy and torque. it is not easy to fully grasp the whole idea unless there are comparison examples against other control motors such as servo motors. By knowing the characteristics and taking on different approaches based on required operations, stepper motors certainly can reduce the cost of the equipment.

The characteristics and technical information of stepper motors are explained below:

Point 1

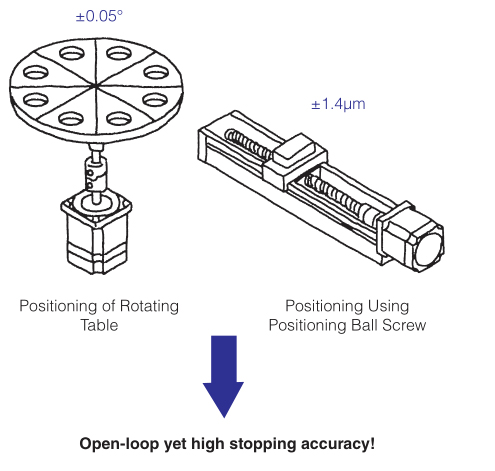

Fantastic Stopping Accuracy!

For example, when converting stopping accuracy ±0.05° of a stepper motor to the ball screw mechanism:

Operating Conditions:

• Motor: RK II Series

• Lead of ball screw: 10mm Stopping Accuracy: ±1.4μm

Generally, accuracy of a ground ball screw type is ±10μm. When using a rolled ball screw type, its accuracy declines to ±20μm, indicating that the stopping accuracy of a stepper motor is much higher than that of ball screw types.

Point 2

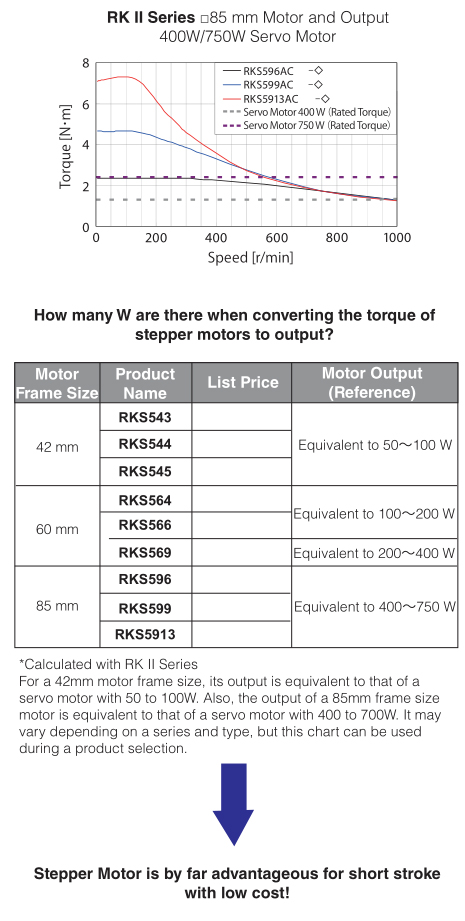

Excellent Mid/ Low-Speed Range!

Example: Torque of a motor frame size 85 mm is equivalent to a rated torque of a 400 W servo motor when 1000 r/min.

Torque in an even lower speed range can be up to 5 times higher. For a short- distance positioning, having high torque in the mid/low-speed range is essential.

Impressive "Stopping Accuracy," "Mid/Low-Speed Range" and "Responsiveness"

Stepper motors have remarkable stopping accuracy, and accurate control with open-loop is possible. For example, when using the RK II Series for positioning of a rotating table, its stopping accuracy is within ±0.05 degrees (with no load). Because stopping position errors do not accumulate between steps, high accuracy positioning is possible. The structure of the stepper motor, which requires no encoder, allows for the simple drive system and low cost.

High torque within the mid/ low-speed range is another great feature of stepper motors. One of the main features of servo motors is to generate flat torque from mid to high speed ranges. Servo motors are suitable for long-stroke operations (many rotations) such as multiple rotation tables. On the other hand, torque characteristics of stepper motors are not flat. The torque curve within the mid/ low-speed range tends to become very high, while becoming very low in the high speed range. Besides the stable rotations in the low speed range, which servo motors struggle with, stepper motors can offer high torque within the required speed range for short-stroke operations (less rotations), thus they are suitable for selecting the desired step angle for multiple rotation tables and inching applications. If you currently use servo motors, based on these characteristics, consider the effectiveness of the RK II's use of up to the maximum speed range. This is due to the short positioning time for the short-stroke operation, thus the motor decelerates and stops before reaching the maximum speed. In other words, most of the time high-speed characteristics are not required. Also, when observing the actual operations, high-speed operations are not performed in many cases, regardless of long or short strokes. Currently, many affordable, good quality stepper motors are available, thus, cost reduction can be achieved if replacing the current motor with a stepper motor.

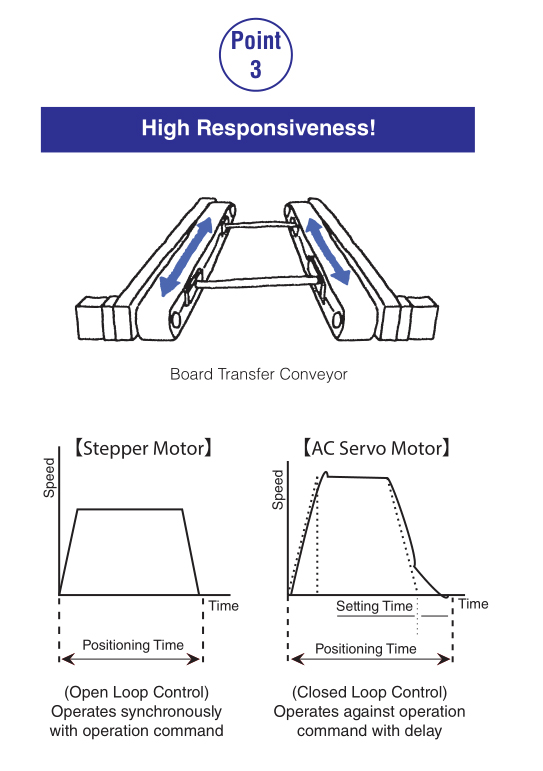

High Responsiveness and Excellent Synchronization

The third remarkable feature of stepper motors is the responsiveness. The open-loop control, which sends one-way commands to the motor, has a very high follow-up mechanism toward commands. While servo motors, which wait for feedback from the encoder, tend to have "delays" against commands, stepper motors operate synchronously with pulse. Therefore, there are very few "delays," resulting in excellent response. For this reason, stepper motors are suitable for applications that require synchronous operations of multiple motors. One example is a board transferring application that requires two conveyors, with one motor mounted respectively, to transfer boards in between the two conveyors.

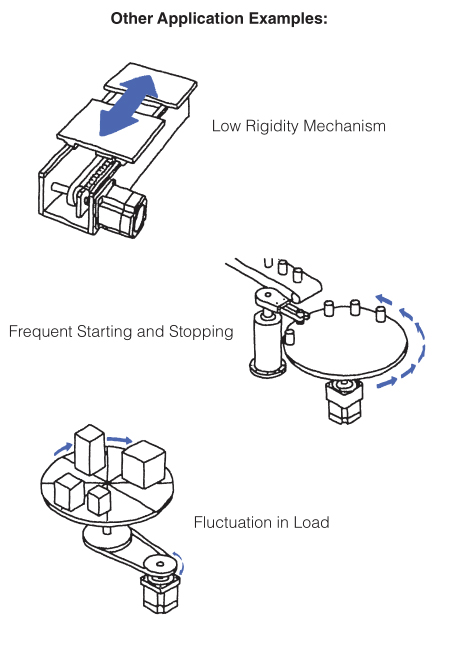

Suitable Applications!

Other than an inching applications with frequent starting and stopping, stepper motors are suitable for positioning of image check processors that dislike vibrations, cam drives that would be difficult to adjust with servo motors, and low rigidity mechanisms such as a belt drive. Furthermore, cost is reduced significantly by replacing a ball screw drive to a belt drive.

Cost Reduction and the Advantage of Great Features

Besides cost reduction, stepper motors have many advantages in terms of performance. I hope this article provides an opportunity for those who have routinely selected servo motors to start considering stepper motors as their options. On the followong pages, detailed information of stepper motors, such as basic structure, system and example applications, is introduced for those who want to learn more about stepper motors.

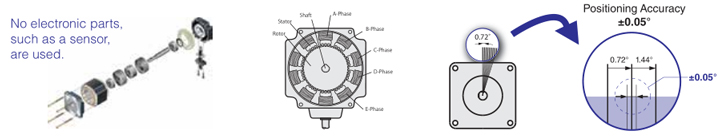

Operation & Structure

A stepper motor rotates with a fixed step angle, just like the second hand of a clock. Highly accurate positioning can be performed with open-loop control thanks to the mechanical structure within the motor.

Accurate Positioning Achieved Only by Mechanical Elements and Accuracy

While having full control of rotation amount and speed, the simple structure of stepper motors was achieved without using electrical components, such as an encoder, within the motor. For this reason, stepper motors are very robust and have high reliability with very few failures. As for stopping accuracy, the representative example is ±0.05° (without cumulative pitch errors), which is very accurate. Because positioning of stepper motors is performed by open-loop control and operated by the magnetized stator and magnetic rotor with small teeth, stepper motors have a higher follow-up mechanism toward commands than that of servo motors. Also, no hunting occurs during stopping of stepper motors. They are also excellent in belt drives, which have low rigidity.

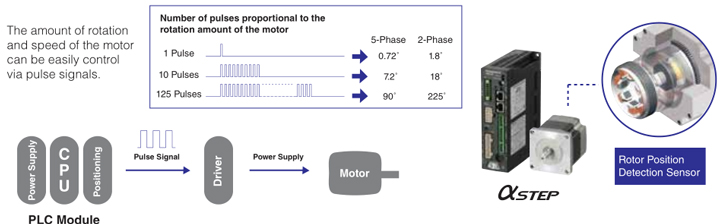

Useful for Speed Control and Position Control

When pulses are input to a driver through a pulse generator, stepper motors perform the step angle according to the number of input pulses. The basic step angle of 5-phase stepper motors is 0.72˚ and 1.8° for 2-phase stepper motors. The rotating speed of the stepper motor is determined by the speed of the pulse frequency (Hz) given to the driver, and it is possible to freely change the motor rotation by simply changing the number of input pulses or frequencies to the driver. Stepper motors not only serve as position control motors, but also as speed control motors with high synchronization.

Stepper Motors Uses:

- High frequency, repetitive positioning of fixed step angles

- Positioning that requires long stopping time due to width adjustment, etc.

- Fluctuating loads and changing rigidity

- Positioning that divides 1 cycle

- Conveying shaft that requires synchronous operation Operating System

Operating System

Simple Control With No Sensor or Feedback

Because it is possible to perform accurate traveling and stopping while synchronizing with the number of command pulses and speed, there is no need for devices, such as a sensor, for positioning. Therefore, the entire system is simple to build. If advanced control, such as an interpolation operation, is not required, the built-in controller function type driver is recommended. Cost is reduced by eliminating controllers, such as a pulse generator and PLC positioning modules.

Built-in Sensor Closed-Loop Type

Although high accuracy positioning is possible with open-loop control, what would happen if a problem occured? In order to avoid such pitfalls, an encoder type or built-in sensor closed-loop control type motor (STEP) can be used.

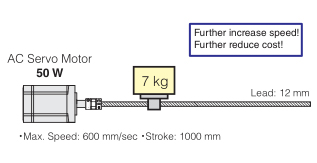

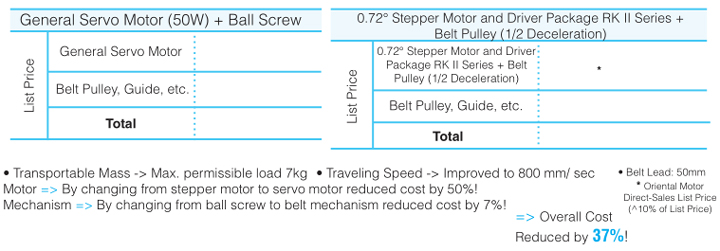

Can the Cost be Further Reduced?

The common issue among design engineers is cost reduction. Is there really no way to further reduce cost? To find out a cost reduction test, with specification enhancements, was conducted based on the ball screw mechanism. The following explains the details of the test:

Mission

Mission

Linear Motion Mechanism � Further Increase Speed ② Further Reduce Cost

[Conditions of the Originally- Planned Equipment]

Mechanism: Ball Screw + Servo Motor Conditions such as a load, speed, and lead, shown on the right, are determined based on the servo motor attached with ball screws and steel plate.

Plan

Change the Mechanism to Belt Pulley

Change the Mechanism to Belt Pulley

• Ball screw if trying to increase speed => Belt mechanism may be more suitable

• Reduce cost significantly if changing to belt is possible => Belt is inexpensive but its low rigidity may affect stability of servo motor operation, even with automatic tuning.

Problems

� Difference in Stopping Accuracy between Screw and Belt... How Much of Stopping Accuracy Is Required?

② Impact of Low Rigidity... Impact on Settling Time, Avoiding Tuning Problem

� Better stopping accuracy with the screw. No problem to change to the belt? => The application's required stopping accuracy is ±0.05 ~ 0.1mm, which is not as accurate as the one for the screw. Therefore, it should be okay to replace with the belt.

② If changing to the belt, rigidity on the mechanism gets low, thus the servo motor movements becomes unstable.

=> Among positioning motors, stepper motors do not have a built-in encoder. For this reason, they require no adjustment and are strong against low rigidity. Their movements are stable regardless of fluctuating loads. If the output is the same, consider stepper motors.

Estimation

Mechanism: Belt Pulley + Motor: Try with Stepper Motor

Results

There Was Much Room for Cost Reduction!

By conducting zero-based review of mechanism as well as the motor selection that assesses characteristics, somehow managed to increase specifications and reduce cost, although the motor size became slightly larger. In the past, motor selection was done based on the ease-of-use aspect and images for no particular reason. After this exercise, differences of operations between servo motors and stepper motors became clear. It was.

Which Has Higher Stopping Accuracy - Stepper Motor or Servo Motor?

Customer Inquiry: Looking for a motor with good stopping accuracy. How much of a difference is there between stepper motors and servo motors?

Assumption: The AC servo motor NX Series is equipped with a 20-bit encoder, thus it should have a fine resolution and good stopping accuracy.

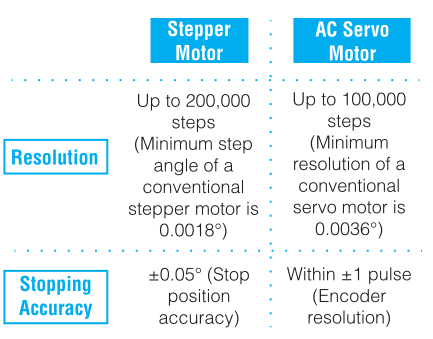

First, it is necessary to clarify the difference between resolution and stopping accuracy: Resolution is the number of steps per revolution and it is also called a step angle for stepper motors. It is needed when considering how precise the required positioning needs to be. Stopping accuracy is the difference between the actual stop position and theoretical stop position.

Does this mean that the AC servo motor equipped with a high accuracy encoder has better stopping accuracy than stepper motors?

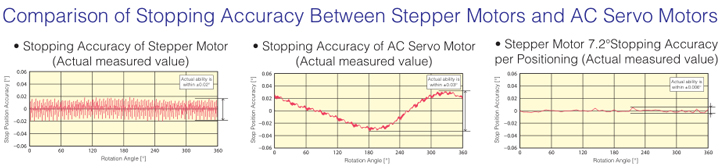

Not quite. In the past there was no issue with the concept of "stopping accuracy of servo motors is equal to encoder resolution within ±1 pulse." However, recent servo motors are equipped with the encoder of 20 bits (1,048,576 steps) which has a very fine resolution. Because of this, errors due to the encoder installation accuracy have a huge effect on stopping accuracy. There- fore, the concept of stopping accuracy has started to change slightly.

According to the comparison charts, stopping accuracy between stepper motors and AC servo motors is almost the same (±0.02°~ 0.03°). Performance of stopping accuracy is the same between the two. Furthermore, accuracy depends on the mechanical precision of the motor for stepper motors, thus if stop position can be done per 7.2°, positioning is done by the same small teeth on the rotor at all times, according to the motor structure. This makes it possible to further improve stopping accuracy.

However, stepper motors may generate displacement angle depending on the load torque value. Also, depending on the mechanism condition, AC servo motors may have wider hunting width as a response to gain adjustments. For these reasons, some caution is required.

Newly Released 0.72° Stepper Motor and Driver Package RK II Series: Compared with the conventional RK Series, the new RK II Series not only achieves lower power consumption and extends functions by implementing the high efficiency motor, but also reduces the size of the driver.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Oriental Motor Corp. USA

Since our founding in Japan in 1885, Oriental Motor globally has been providing the optimal motion systems as part of our total service, to meet the widest market demands. We manufacture and sell AC Motors, Stepper and Servo Motors, Linear and Rotary actuators, Network Solutions, Accessories and Thermal Management solutions. Oriental Motor's sales and service network is international, with offices throughout North America, Europe and Asia.

Other Articles

Talking PACK EXPO with Oriental Motor USA Corp.

Development of Battery-Free Multi-Rotation Absolute Encoder

More about Oriental Motor Corp. USA

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product