The booth demonstration showcases a unitizing approach to robotic palletizing in which loads are built directly onto slip sheets or conveyor, a practice common in manufacturing operations serving a variety of international markets or handling empty containers.

Talking PACK EXPO with Doug Stoll of Intelligrated

Doug Stoll | Intelligrated

Your company will be exhibiting at PACK Expo, what is it that makes this an important event for your company?

PACK EXPO is an opportunity to connect with prospects and existing customers firsthand, get a sense for their goals and challenges, and show them some of our latest innovations. But the show also provides value beyond that. It’s a meeting of minds, with a variety of perspectives coming together to push the industry forward, from end users and integrators to packaging suppliers and component manufacturers.

What can a visitor to your booth expect to see this year?

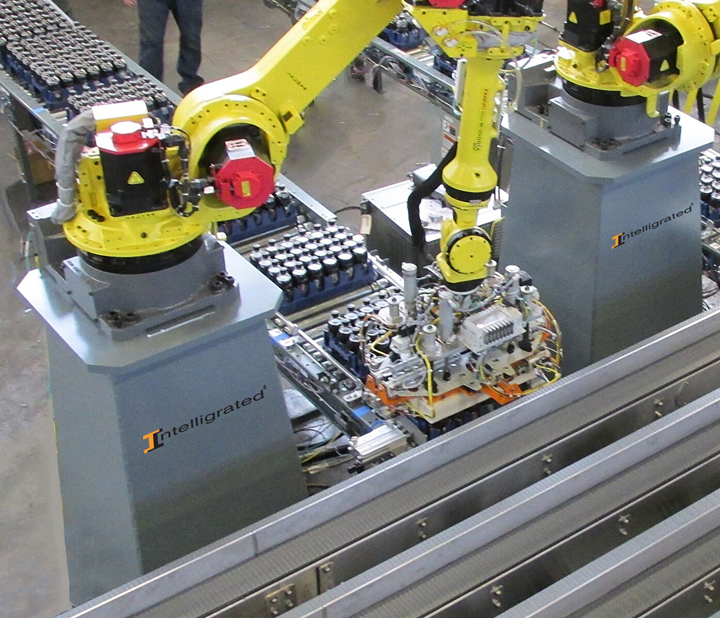

At booth 3906 in the central hall, Intelligrated will showcase robotic palletizing and depalletizing solutions. The robotic solutions on display enable reliable, high throughput with reduced labor requirements and offer the flexibility to accommodate a variety of packaging types, stacking patterns and layout constraints. The robotics are supported by our motor driven roller (MDR) conveyor to feed individual cases to the palletizing cell and Palmat™ conveyor to transport completed loads.

Any new products you will be introducing?

The booth demonstration showcases a unitizing approach to robotic palletizing in which loads are built directly onto slip sheets or conveyor, a practice common in manufacturing operations serving a variety of international markets or handling empty containers.

Unitized loads travel to the robotic depalletizer on Intelligrated Palmat™ conveyor, a full-width, heavy-duty modular plastic belt designed for applications with column-stacked or unitized loads that are unstable or difficult to handle. Finally, the robotic depalletizer unloads items and places them on MDR conveyor for transportation back to the palletizer. The demonstration uses a Rockwell Automation-based HMI for clear visualization of equipment status and diagnostics.

Attendees can also learn about our IntelliGen™ palletizing software. IntelliGen offers a user-friendly, flexible solution to easily adjust pattern and load configurations according to changing product dimensions and other variables, without the need for a service call or complex external software programs.

Representatives from our Lifecycle Support Services will be on hand to discuss system assessments. These are part of our comprehensive lifecycle management framework. Engineers with equipment-specific expertise visit customer sites to evaluate component condition and provide recommendations for service, replacement, upgrades or modifications. Ultimately, these assessments help end-users realize maximum system uptime and performance.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see?

Our industry continually fosters new innovations, from increasingly capable robotic solutions to more efficient packaging materials. PACK EXPO is a great chance to look at emerging trends and technologies that are making an impact in our space, and stay on the leading edge, allowing us to account for current and future challenges.

It’s also a chance to see fresh faces. Events like the future innovators robotics showcase and the amazing packaging race give engineering students an introduction to packaging, robotics, supply chain and related fields represented at the show. Events like these are critical to address the well-documented skilled labor shortage facing our industry, and help establish a pipeline for the next generation of the industry’s workforce.

PACK EXPO has many educational sessions & demos, is your company involved in any of them this year?

Intelligrated is participating in the aforementioned amazing packaging race, with an interactive challenge at our booth ready to give students a hands-on look at how their education translates into real-world applications. Events like these give students exposure to Intelligrated and our approach to solving the challenges our customers face, while allowing us to gauge the aptitude of students studying related fields and identify candidates for internship and co-op programs.

When you book a booth for a tradeshow like this what are your expectations and what does your company hope to accomplish at the event?

Like most companies, Intelligrated regards shows like PACK EXPO as an important vehicle to make connections with customers and tell our history regarding solutions and services. It’s also a chance to take the pulse of the industry. Are there any new challenges on the horizon? How are certain trends manifesting themselves in our space, such as Industry 4.0? Are there advances in certain component technologies that we can leverage in our solutions?

Ultimately this helps us stay on the leading edge of the industry, with solutions designed for the challenges of today and tomorrow.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product