The ifm Obstacle Detection System (ODS) optimizes the robot's overall performance by treating obstacle detection as a holistic system rather than just a camera. It provides reliable obstacle detection to protect people, equipment, and mobile robots.

The ifm Obstacle Detection System (ODS)

Product Q&A with | ifm Efector, Inc.

Tell us about your product and what you feel sets it apart from similar products.

.png) The ifm Obstacle Detection System (ODS) uniquely serves the autonomous mobile robotics market by offering an off-the-shelf software solution onboard the ifm O3R robotic perception platform. It optimizes the robot's overall performance by treating obstacle detection as a holistic system rather than just a camera. It provides reliable obstacle detection to protect people, equipment, and mobile robots in real-world applications.

The ifm Obstacle Detection System (ODS) uniquely serves the autonomous mobile robotics market by offering an off-the-shelf software solution onboard the ifm O3R robotic perception platform. It optimizes the robot's overall performance by treating obstacle detection as a holistic system rather than just a camera. It provides reliable obstacle detection to protect people, equipment, and mobile robots in real-world applications.

Tell us about the R&D behind this product. Who is this product designed for? What problem is it solving?

This product is designed for mobile robotic OEMs to reduce friction in the development, integration, and deployment of their vehicle fleets. Previously, every company building a new autonomous mobile robot had to develop and maintain a proprietary obstacle-detection system, even though revenue depended on solving a specific use case. This pulled significant developer capacity from a company’s core intellectual property and business goals. The ifm ODS solves this problem by providing an off-the-shelf solution that ensures mobile robots avoid collisions with people and equipment, freeing developers to focus on building robots that solve real-world problems. This accelerates the time to market for new mobile robots.

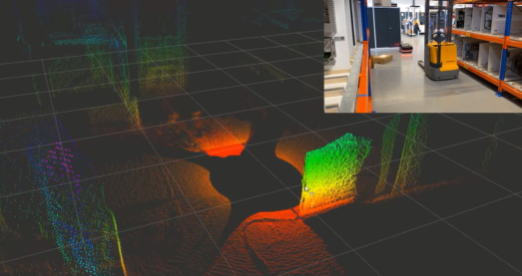

While safety LiDAR ensures mobile robots avoid hitting people, robots that rely on it for obstacle detection often have blind spots above and below the safety LiDAR plane. When deployed in the real world, this leads to expensive robots colliding with predictable obstacles that safety LiDAR cannot detect, such as cantilever loads or raised fork tines.

Give us an idea on the installation process.

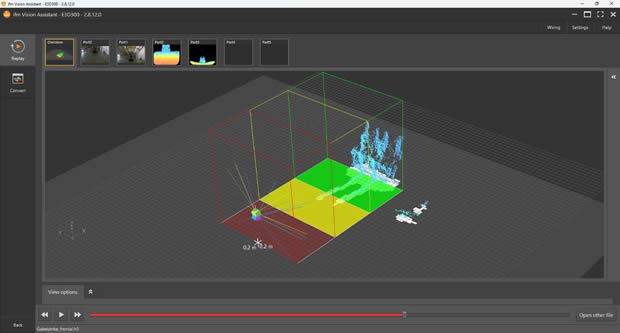

The installation process varies depending on the robot's geometry and the use case. In general, the developer will design for the best camera mounting positions based on what region of interest they need to measure. Then, they mount the camera heads and connect them to the central VPU. Through ifm’s free Vision Assistant software, the VPU understands each camera's location and aggregates that data to provide a single view of obstacle detection across the entire robot.

How is your company setup to support the users of your products.

We have an entire website dedicated to providing all the engineering technical support a roboticist needs, without having to navigate any marketing materials. That separate domain is: www.ifm3D.com. Additionally, we have a team of robotics developers who provide technical support from locations in the US, EU, and APAC.

What feedback have you received from the field? Can you share a use case and the results?

We have customers in all major regions of the world using ODS, and the response has been overwhelmingly positive for reducing integration friction. While we don’t have case studies published yet, demonstrations of the ODS capabilities are available to view by visiting: https://www.ifm.com/us/en/us/industries/amr/id/ods/obstacle-detection-system-capabilities”

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product