We needed a powerful configuration platform so customers would have access to complete assemblies, could easily put systems together using automated snaps, and manage operational states

Glide-Line Conveyor Case Study: Automating in-context Conveyor Configuration With Solidworks

Contributed by | Dassault Systèmes

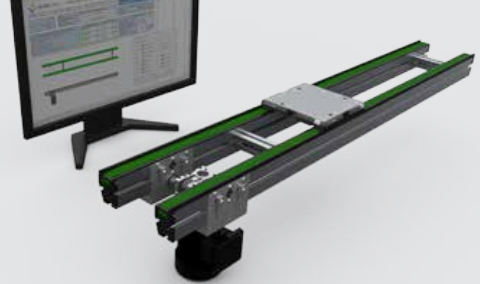

Automation system designers have long desired an in-context configurator—one that combines access to solid modeling tools, prices, part numbers, and capabilities in real time—instead of configurators that deliver “fixed” models with no built-in intelligence. Making models intelligent—as well as incorporating advanced snap-to mating features, allowing multiple operational states, and allowing automatic ordering of configured systems—will streamline supplier interactions, save time, and reduce costs. Companies who supply engineered-to-order industrial equipment have also wanted to let customers specify and make changes to layouts using a robust, in-context configurator, because it would enable them to shorten delivery lead-times, save time, and drive out costs. The introduction of the Glide-Line™ brand of configurable multistrand panel—and pallet-handling conveyor solutions meets all these needs.

Glide-Line is a subsidiary of NCC Automated Systems, Inc., which has helped clients overcome material handling challenges for over 30 years. Within NCC’s customer portfolio are some of the longest-established brands, including The Hershey Company, PepsiCo, Unilever, General Mills, Starbucks, Procter & Gamble, and Pinnacle Foods.

In 2013, NCC Automated Systems launched the Glide-Line brand of configurable conveyors. In 2015, the company introduced the IMPACT! (Interactive Modeling Program and Application Configuration Tools) application for configuring Glide-Line conveyor solutions. According to President Kevin Mauger, the company’s migration from AutoCAD® 2D design tools to the SOLIDWORKS® 3D development platform in 2008—along with Product Development Engineer Ron Schwar’s visit to the SOLIDWORKS World 2016 Conference—made it all possible.

“We needed a powerful configuration platform so customers would have access to complete assemblies, could easily put systems together using automated snaps, and manage operational states, as well as use the specific configuration that they created to obtain a firm price and place an order,” Mauger recalls. “Our assessment, that only SOLIDWORKS had the intelligent mating technology, open Application Programming Interface (API), and user community necessary to achieve our goals, has proven accurate.”

After evaluating potential solutions, Glide-Line chose SOLIDWORKS—implementing SOLIDWORKS Professional design, SOLIDWORKS Premium design and analysis, and SOLIDWORKS Composer™ technical communication software—because it’s easier to use, provides greater capabilities, and includes the technologies that led to the IMPACT! configurator. “The maturity of SOLIDWORKS was apparent because Autodesk® Inventor® was missing a lot of features that SOLIDWORKS provided,” Schwar recounts. “We also felt good about our SOLIDWORKS reseller, who has provided quality training and support.”

CONVEYOR CONFIGURATION WITH IMPACT!

Schwar literally walked into the company’s configuration solution when he attended GoEngineer’s GoAutomate technical session at the end of the SOLIDWORKS World 2016 Conference. “Those were the most important 15 minutes of the entire trip,” Schwar stresses.

Developed by SOLIDWORKS reseller GoEngineer, GoAutomate is an open-source tool based on Microsoft® Excel that helps customers automate SOLIDWORKS models directly within Excel, allowing users to control features, dimensions, configurations, mates, and more. “The GoAutomate session was the last one, and I actually was asking myself how much cash I had on me when I discovered it was free. GoAutomate is the bridge connection to the SOLIDWORKS API and the engine of our IMPACT! configuration tool. The combination of SOLIDWORKS, its API, GoAutomate, and Excel enabled us to develop a configurator with no limitations or restrictions, providing a simplified, flexible solution without plug-ins, new software, or add-ins.”

IN-CONTEXT DESIGN SAVES CUSTOMERS TIME AND MONEY

Because IMPACT! utilizes a customer’s system configuration data to recommend the best-fit options from a range of SOLIDWORKS models—with literally millions of possible configurations in total—and lets customers make in-context design changes within SOLIDWORKS, with real-time pricing feedback, the solution has been well received by customers. “I love two things,” says DeWayne Merritt, an engineer at AutoLiv. “Accurate CAD files with high detail and the time this software saves me.”

In addition to helping customers save time and money, the combination of SOLIDWORKS and the IMPACT! configurator has enabled Glide-Line to offer industry-leading aggressive lead-times. “Now that we’ve introduced the first intelligent, in-context conveyor configurator, nobody can deliver as quickly as we can,” Mauger notes. “The SOLIDWORKS configurator has allowed us to deliver systems in half the time, and because the automation also helps reduce cost, we can deliver less expensive products faster than the competition.”

TAKING IT UP A NOTCH WITH GLIDE-LINE 360

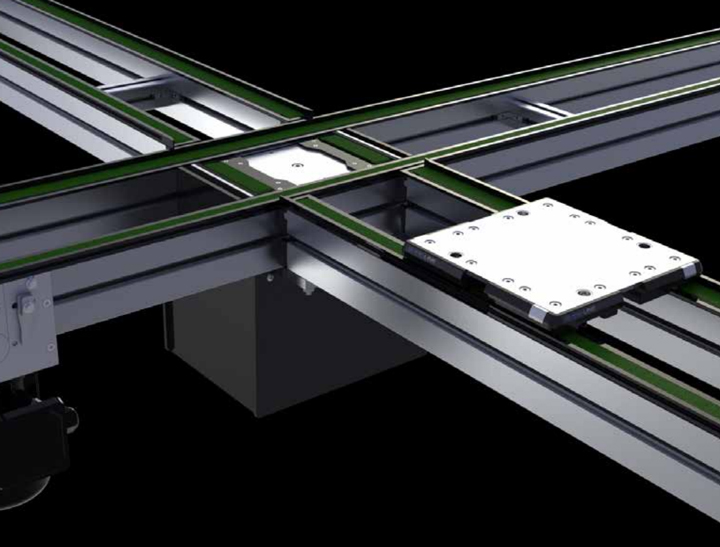

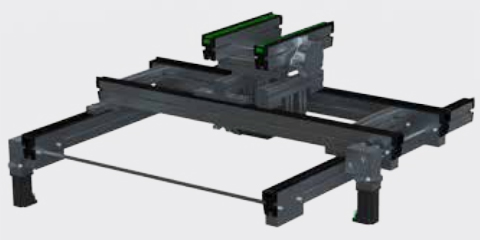

Glide-Line recently introduced the Glide-Line 360 conveyor line, which combines powered-timing-belt-based conveyors working with the company’s family of devices to accomplish almost any type of movement (e.g., orientation change, sort, or shift) in a small space. Designed entirely with SOLIDWORKS, the Glide-Line 360 makes it possible to shuttle, divert, merge, sort, stack, lift, lower, transfer, and turn a pallet or pallets cost-effectively.

Using SOLIDWORKS and IMPACT!, Glide-Line enables its customers to use their own system configuration data to recommend the best-fit options from a range of SOLIDWORKS models — with literally millions of possible configurations in total — saving time and money in the process.

“The automation that we’ve been able to achieve on the SOLIDWORKS platform is incredible,” Mauger adds. “It gives us the speed and flexibility that we need to better serve our customers, introduce innovative products, and grow our business.”

Challenge:

Develop 3D model library of conveyor components, assemblies, and subassemblies, and then combine it with intelligent mating technology via Application Programming Interface (API) manipulation to provide customers with real-time, in-context configuration, editing, and ordering of conveyor designs.

Solution:

Implement SOLIDWORKS Professional design, SOLIDWORKS Premium design and analysis, and SOLIDWORKS Composer technical communication software, and leverage the open SOLIDWORKS API in conjunction with the GoAutomate open-source automation tool from SOLIDWORKS reseller GoEngineer.

Results:

- Cut delivery lead-times in half

- Improved user experience with unparalleled power and flexibility

- Introduced first intelligent, in-context online conveyor configurator

- Helped customers save time and money

Glide-Line

255 Schoolhouse Road

Souderton, PA 18964 USA

Phone: +1 215 721 1900

www.glide-line.com

About Dassault Systèmes

Dassault Systèmes, the 3DEXPERIENCE® Company, provides business and people with virtual universes to imagine sustainable innovations. Its world-leading solutions transform the way products are designed, produced, and supported. Dassault Systèmes’ collaborative solutions foster social innovation, expanding possibilities for the virtual world to improve the real world. The group brings value to over 210,000 customers of all sizes in all industries in more than 140 countries

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product