Focus Auto Design Inc. originally purchased a used robot two years ago to make the jump into automating their business. However, they were manually programming this robot which took time and resources that held their business back from its optimal performance.

Are You Still Manually Programming Your Robot? Why Not Fully Automate!

Are You Still Manually Programming Your Robot? Why Not Fully Automate!

Are You Still Manually Programming Your Robot? Why Not Fully Automate!

Contributed by | OCTOPUZ Inc.

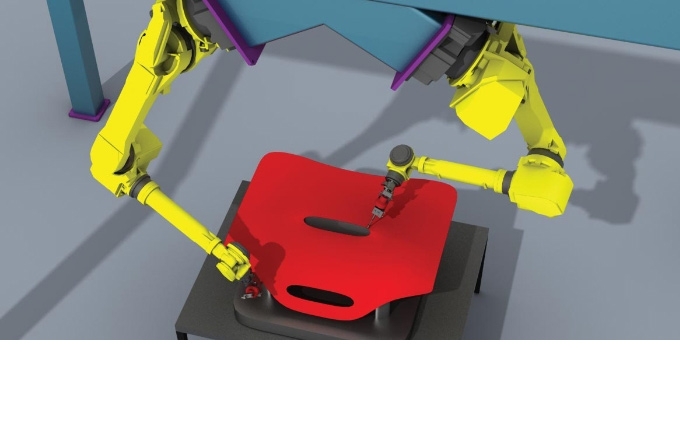

For over 30 years Focus Auto Design Inc, based in Calgary AB, has been manufacturing OEM appearance accessories. Recently, with a change in their manufacturing processes they have successfully launched an innovative new product known as the Tough FormFit Guard , a rouged hood protector manufactured from acrylic capped ABS. This new product is thoughtfully designed to emulate the OEM ABS finishes found on many grills, scoops and fender flares resulting in a seamless, sharp and aggressive look. This product not only provides protection to the most vulnerable part of the vehicle but it also offers great value, style and easy installation – no drilling necessary!

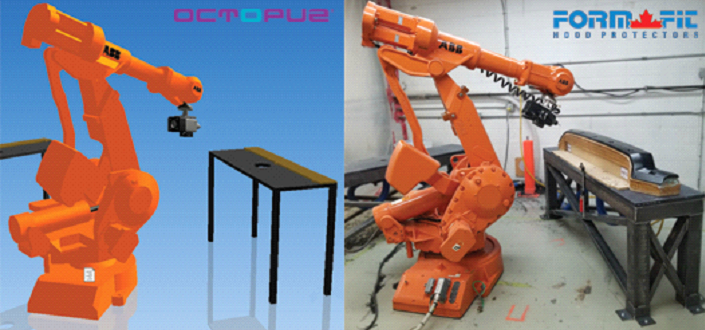

Before investing in OCTOPUZ software, Focus Auto Design Inc. originally purchased a used robot two years ago to make the jump into automating their business. However, they were manually programming this robot which took time and resources that held their business back from its optimal performance. They ultimately decided to take the leap into a fully automated process with their ABB 4400 robot combined with OCTOPUZ, which was a big decision for their business that paid off.

The ABB programmed with OCTOPUZ software trims their hood protectors more accurately than they had ever achieved, and makes their business much more efficient with both materials and other resources. The addition of OCTOPUZ means that Focus Auto Design can deliver more control, faster programming, better quality and improved safety to their manufacturing. Now, rather than being limited by the speed of their manual programming, they can keep up with the robots capabilities with OCTOPUZ increasing their shops capabilities. They can deliver products now much faster and with a high level of manufacturing.

Roger Kinzel, Research and Development at Focus Auto Design was interviewed for this article, saying:

“We no longer have to “Learn Mode” the robots. This is such a tedious task that it takes well over a complete day to accurately teach a good trimming path. In addition, the OCTOPUZ software gives us the ability to see our complete workspace including tooling in 3D on the computer. We can see mistakes long before they happen saving us valuable time during our initial design concepts for new products.”

A year into their OCTOPUZ software use, they now have one of the best problems any manufacturer can have: they cannot keep up with the robot! Their efficiency has skyrocketed as well as their business. They can deliver products now three times faster than before using OCTOPUZ.

“After less than a year working with OCTOPUZ we can have a perfect robot trimming path complete in an hour, including a nice warm cup of coffee and not a cold shop floor. Previously if we had to make a change to a pattern the robotic re-learning took half a day. With the software a change can be made as quickly as you can use the computer allowing for a very quick revision.” – Roger Kinzel

OCTOPUZ has allowed the expansion of Focus Auto Design into new products lines, with Roger saying “We have been able to successfully bring our newest product line, “Tough FormFit Guard” to meet our very high internal standards and launch a complete new line of products for many applications. Without this software we would still be working on patterns and doing hand work, wasting valuable company time and money.”

We talked to our Canadian reseller, In-House Solutions, where Radu Biris, Senior Account Manager, for their Alberta office shared the current economic situation in Alberta:

“Cutting costs and improving productivity in Alberta is the key to success for every company in order to stay competitive and be able to diversify. Our customers have to find new innovative ways to compete and grow in this new environment. Our goal here at In-House Solutions is to make this transition from the old times into the future as easier as possible for all our customers. Robotics is one of the “keys” that companies can use to open the doors to the world and be ready for tomorrow.”

We are often faced with the question: Why choose OCTOPUZ for your offline robot programming needs? Roger had some great advice for those searching for alternative programs:

“Other robot software packages only work with specific brands of robots. OCTOPUZ comes with a very large selection of robots and an online catalog to find exactly what you are looking for. We bought a new robot after 1 week of using the software to suit our application better. Looking back it would have been a better idea to purchase OCTOPUZ first! Any new robots we buy in the future will use the same license, allowing a single user to control hundreds of robots.”

In terms of the return on investment from OCTOPUZ, Rogers leaves us with this parting comment:

“Without OCTOPUZ our trimming operations would take too many resources to complete making the products cost more. We honestly spent more money internally trying to figure things out without the software than the cost of OCTOPUZ. It has more than paid for itself and we are incredibly satisfied. Not only do we save time and money with the software but we are able to pass the savings along to our customers. Producing a better part at a lower price!”

About OCTOPUZ Inc.

OCTOPUZ is an intelligent offline robotic programming and simulation software ideal for any sized company. It offers the ability to program, simulate and generate code for multiple robots, simultaneously, with support for most robot brands in any configuration. OCTOPUZ is fully customizable to our customer’s needs, and our extensive support will provide assistance before, during, and after the sale.

OCTOPUZ is an intelligent offline robotic programming and simulation software ideal for any sized company. It offers the ability to program, simulate and generate code for multiple robots, simultaneously, with support for most robot brands in any configuration. OCTOPUZ is fully customizable to our customer’s needs, and our extensive support will provide assistance before, during, and after the sale.

About In-House Solutions

In-House Solutions provides CNC, Robotics, and QC markets with software, technical services, and educational materials. Our software solutions include: Mastercam (CAD/CAM for CNC Machines), OCTOPUZ (Offline Programming & Simulation for Robots), CIMCO (CNC Communications) & Verisurf (Metrology/Quality Control).

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product

Elmo Motion Control - The Platinum Line, a new era in servo control

Significantly enhanced servo performance, higher EtherCAT networking precision, richer servo operation capabilities, more feedback options, and certified smart Functional Safety. Elmo's industry-leading Platinum line of servo drives provides faster and more enhanced servo performance with wider bandwidth, higher resolutions, and advanced control for better results. Platinum drives offer precise EtherCAT networking, faster cycling, high synchronization, negligible jitters, and near-zero latency. They are fully synchronized to the servo loops and feature-rich feedback support, up to three feedbacks simultaneously (with two absolute encoders working simultaneously). The Platinum Line includes one of the world's smallest Functional Safety, and FSoE-certified servo drives with unique SIL capabilities.