OCTOPUZ will be exhibiting at IMTS 2018 located at booth #236036. At IMTS we will be showcasing the latest version of OCTOPUZ 2.0.3 released fall 2018.

Contributed by | Octopuz

Tell us about your company.

Headquartered in Waterloo, Ontario, OCTOPUZ Inc. provides offline robot programming and simulation software for businesses of all sizes, from small shops to global corporations. Our focus is to provide a robotic software solution that not only enables companies to reach a higher level of efficiency with their processes but that also opens opportunities for them to enter new markets and expand their business potential. Our business was built on the concept of taking complex robotic programming and making it easy.

Offline Robotic Programming – Complex Made Simple

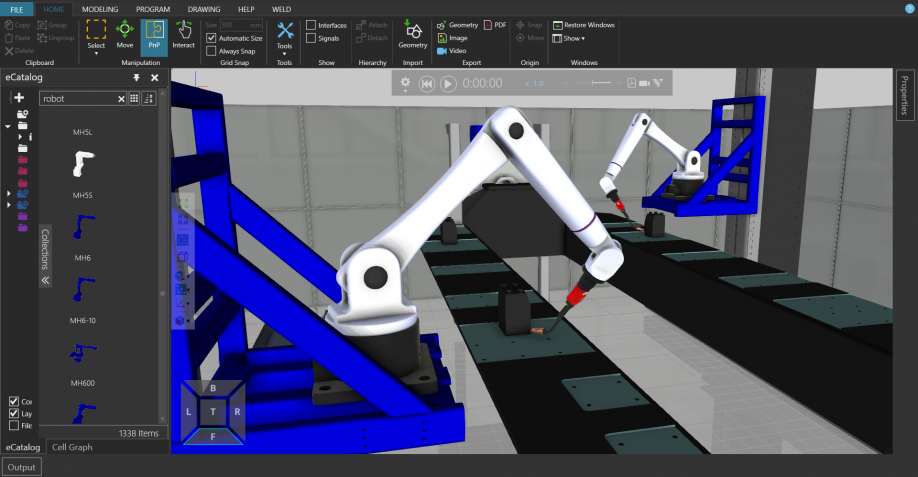

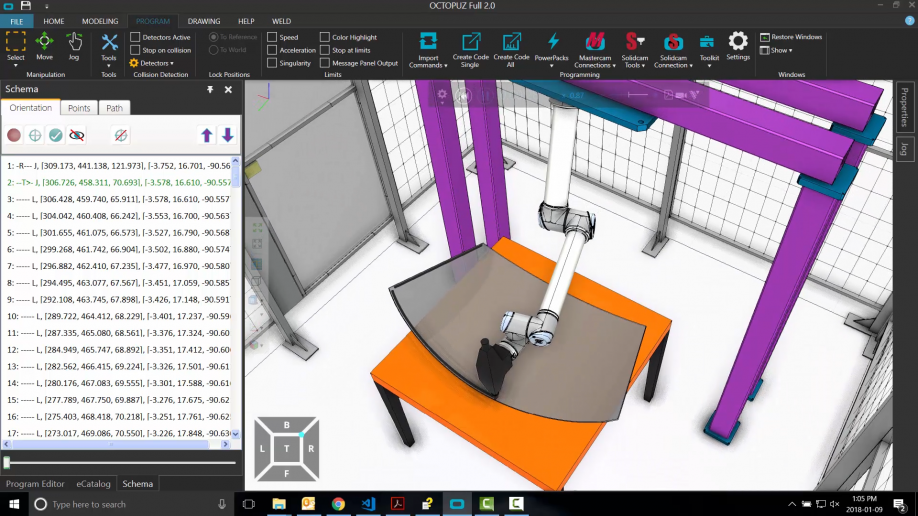

OCTOPUZ is a complete solution that enables users to program and generate robot code offline while visualizing their entire manufacturing process. In addition to its simulation and material handling capabilities, it can generate or import path information from Mastercam for a variety of applications including edge following, material removal and fabrication. OCTOPUZ offers a powerful, flexible and customizable environment where users can program multiple robots simultaneously without interrupting production.

Your company will be exhibiting at IMTS, what is it that makes this an important event for your company?

The IMTS show is a great opportunity for us to network with all the project stakeholders that we deal with, in one place at one time. This event often results in the discovery of new ways to work synergistically with our partners, both old and news, all while learning about the new exciting direction that manufacturing is heading in.

Highlight 2 or 3 products you will be showcasing at the event?

At IMTS we will be showcasing the latest version of OCTOPUZ 2.0.3 released fall 2018. This new release includes improvements to the OCTOPUZ importing capabilities for robot backups and the optimization of the user experience such as the Auto Save, half plane visualization and externals QuickConfig Features.

We will also be presenting the OCTOPUZ VR capabilities – a great sales tool for integrators as a proof of concept for their clients. Why not visualize and walk through your entire robot cell before the real cell is designed and created.

IMTS has many educational sessions & Demo’s, is your company involved in any of them this year?

OCTOPUZ is not involved in any educational sessions and demos, but our team will be conducting demo’s in our booth of the latest version of OCTOPUZ 2.0.3 and its capabilities.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions you plan on attending?

When the OCTOPUZ team gets a chance to walk the exhibit hall floor, we will be most interested to see the latest technologies being developed by existing or potential new partners.

When you book a booth for a tradeshow like this what are your expectations and what does your company hope to accomplish at the event?

At IMTS we hope to generate new opportunities, build and strengthen partner relationships, and learn about the latest technologies on display at this show.

A tradeshow of this magnitude is extremely busy and stressful for the staff of exhibiting companies. Any fun things or places your team can suggest in Chicago to help unwind?

Nothing beats deep dish pizza and a baseball game!

Featured Product

OCTOPUZ Robot Programming Software

Program and simulate ALL your robots with OCTOPUZ offline software. OCTOPUZ specializes in path sensitive robotic applications such as welding, fabrication, edge following (waterjet, deburring, laser cutting), material removal (2D & 3D machining), and pick & place. Easy to learn, it directly supports paths from your favorite CAM system, has a library of over 15 different types of robot brands, can cut path generation by over 50% and is fully customizable to your unique needs. Program and simulate multiple robots simultaneously in any configuration! Responsive technical assistance from OCTOPUZ before, during and after sale via training, support and cell development make OCTOPUZ the software of choice.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product