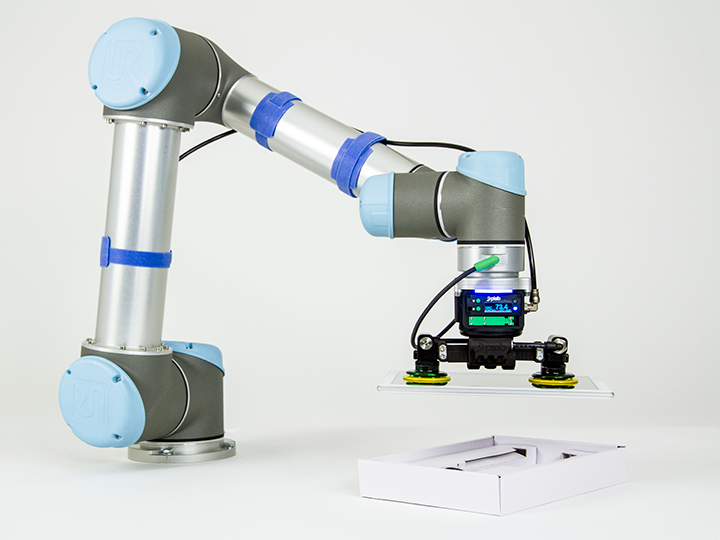

Booth #8360 - piCOBOT®, an EOAT designed for collaborative robots (cobots) using brand new technology from Piab to handle products on a Universal cobot.

Contributed by | PIAB

Tell us about your company.

Piab provides smart solutions for the automated world, helping thousands of end users and machine producers in e-commerce logistics, food, pharma, automotive and other manufacturing industries to improve energy-efficiency, productivity and working environments. With almost 500 employees, Piab is a global organization, serving customers in almost 70 countries from a network of subsidiaries and distributors. By leveraging the ongoing technological development in automation and robotics, and targeting high-growth segments and geographies, Piab's vision is to become the global leader in gripping and moving solutions

Your company will be exhibiting at AUTOMATE, what is it that makes this an important event for your company?

It is an opportunity to showcase our company’s smart gripping and moving solutions to help our customers be more efficient and productive while saving energy in the automated world.

What makes your booth a must visit for AUTOMATE Attendees?

piCOBOT®, an EOAT designed for collaborative robots (cobots) using brand new technology from Piab to handle products on a Universal cobot.

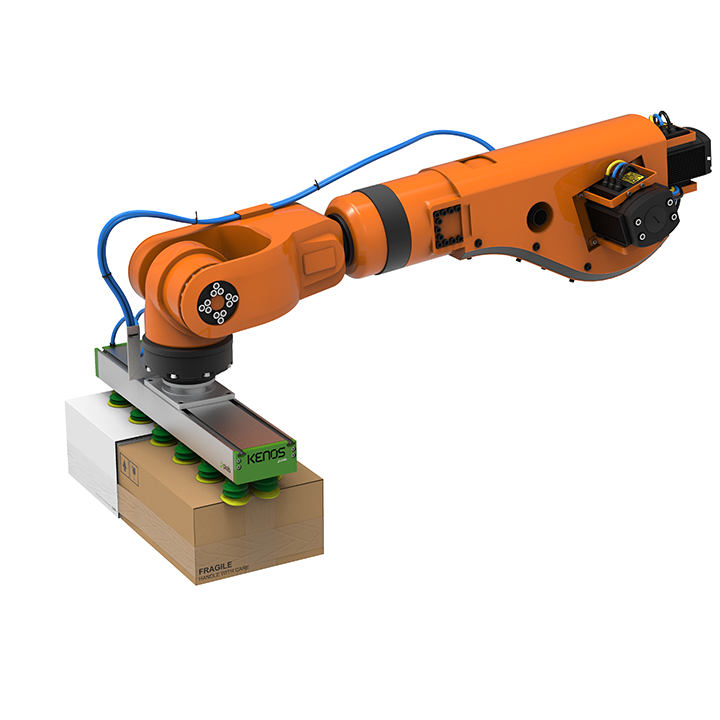

Kenos® vacuum gripper seen on a Fanuc robot handling a matrix of objects guaranteeing optimal grip.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

It is always interesting to see what the robot manufacturers show for the newest cutting-edge technology that can’t be seen at any other trade show.

The factory floor is undertaking rapid advancements, be it automation, robotics, machine vision or data. Automation Technology is a huge part for many manufacturers, give us an idea on how your company and product is being utilized now in the smart factory.

Piab’s piSMART® – more intelligent and cloud-connected versions of the company's most advanced vacuum technology products, kitted out for smart factories. piCOMPACT®23 SMART is one of the first products. Fully integrated control functions for on/off, blow, vacuum sensing and diagnostics. IO-Link provides smart data to support predictive maintenance.

Give us your thoughts on what the future holds for manufacturers and automation technology.

In some respects, the future is now with a large amount of current smart-technology Industry 4.0 products communicating with each other providing for great efficiencies. Moreuser-friendly apps for mobile phones and other handheld devices gathering data for Industry 4.0 factories, where processes and components are automatically guided, controlled and verified.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Piab Inc.

Piab provides smart solutions for the automated world, helping thousands of end users and machine producers in e-commerce logistics, food, pharma, automotive and other manufacturing industries to improve energy-efficiency, productivity and working environments. By leveraging the ongoing technological development in automation and robotics, and targeting high-growth segments and geographies, Piab's vision is to become the global leader in gripping and moving solutions.

Other Articles

ProMat Q&A with Piab

Reinventing Intralogistics

The dm Drugstore Distribution Center Relies on Piab Suction Cups

More about Piab Inc.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product