Automation is making conveyors a more integral component because of the contributions they're making to the overall efficiency and productivity of today's processing and packaging lines.

Staying Competitive with Automation

Staying Competitive with Automation

John Kuhnz, Vice President – Engineered Solutions | Dorner Conveyors

Increasing the speed of their packaging line is one of the leading requests we receive from customers. And for good reason. Faster speeds often equal higher rates of production, which can lead to greater profits. Of course, simply cranking up the speed of your conveyors won’t get you there…but automation will.

The technology driving automation is constantly evolving; enabling conveyor systems to be more high-tech than ever before. In fact, automation is making conveyors a more integral component because of the contributions they’re making to the overall efficiency and productivity of today’s processing and packaging lines.

So, how can automation in your conveyor system help a processing or packaging line increase productivity? The first step is to complete an efficiency audit of the entire line. Is your current line meeting production goals set forth by the company? Is it set up to accommodate an increase of output if required? How well are the conveyors integrating with other components on the line? These are just a few opening questions to consider in evaluating the effectiveness of your line.

To obtain the best results from your audit, consider partnering with a reputable conveyor OEM or packaging systems integrator. These are experts in identifying shortcomings in your conveyor system, as well as evaluate, the efficiency of how product is arriving into the conveyors and where it travels after that.

Your efficiency audit will help you understand the relationship between each component, and how they interact with each other to best maximize the overall throughput and improve Overall Equipment Effectiveness (OEE).

OEE is becoming an industry standard for measuring productivity. Essentially, it identifies the percentage of manufacturing time that is actually productive. When used properly, OEE is a powerful tool that helps companies define, visualize and ultimately eliminate equipment losses and waste. Since each process on the line affects the next component, and so on, it’s advisable to audit all equipment along the line to determine if there is a weak spot affecting output and lowering a company’s OEE.

Learn more about how conveyors affect OEE.

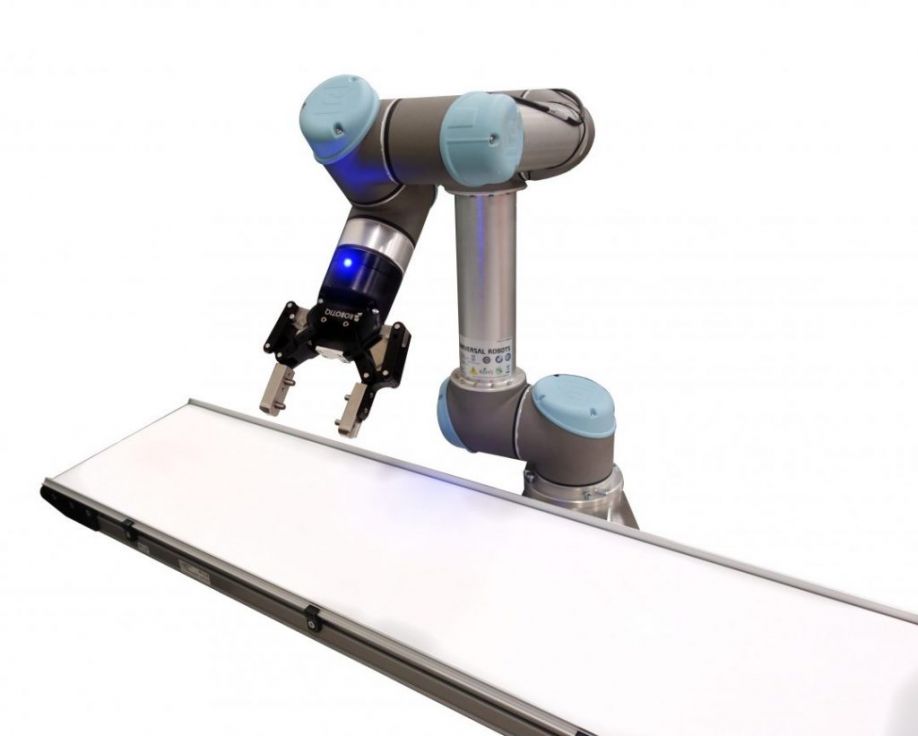

In the past few years we’ve seen a greater push in adding robotics into processing and packaging lines. Robots are becoming smaller and faster, which make them easier to integrate into applications found in automation, food handling and processing, medical, pharmaceutical, life sciences and other industries. Robotic solutions have found great acceptance within medical, pharmaceutical and life sciences in particular, because of their required cleanroom processing. New advancements in robots see them operate cleaner and more efficiently, which complements cleanroom standards.

The advent of robotics in processing and packaging is also leading to a new trend regarding labor. While some may believe that robotics is eliminating jobs, we’re seeing companies repurpose labor as a result of their robotic systems. Employees who were handling more tedious or repetitive jobs now accomplished by robots are being relocated elsewhere within the plant, and given new opportunity to shine.

Numerous resources are available to help you automate your facility. If designed and implemented correctly, your processes will become more efficient with automation, and position you to effectively engage your customers and remain competitive..

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product