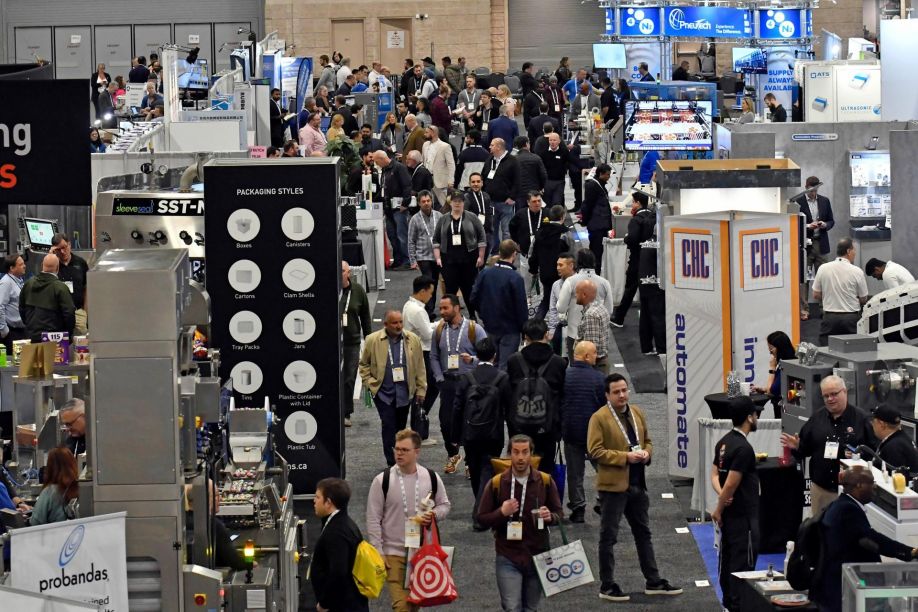

PACK EXPO Southeast 2025: The Future of Packaging & Processing Arrives in Atlanta

This brand-new regional show promises to connect industry leaders, innovators and decision-makers while showcasing cutting-edge technologies that will shape the future of manufacturing across more than 40 vertical markets.

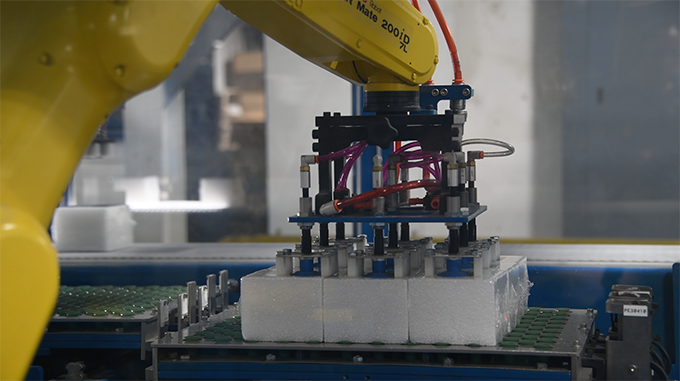

Packaging Robots Industry Statistics: Market to Reach USD 19.0 Billion by 2033

As industries seek more innovative ways to meet consumer demands and handle complex packaging tasks, the role of packaging robots becomes more pivotal. This trend is expected to continue, fostering further growth and development in the robotics sector.

PACK EXPO 2023 Product Preview

PACK EXPO 2023 takes place September 11th - 13th in Las Vegas, Nevada. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Insights from Brenton Engineering Company

Equipment Flexibility Key to Accommodating Changing Applications , The Upside of Automation on Your End-of-Line Operation, The Value of Project Management

Intelligent Box Opening Device (IBOD)

You have lots of cartons coming into a typical warehouse, let's say 600 boxes per hour, and razor blades are used to cut these boxes while keeping up with intake speeds. This invites risks and employees still get injured, despite safety precautions.

PACK EXPO 2022 Product Preview

PACK EXPO 2022 takes place October 23rd - 26th in Chicago, Illinois. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

How Commercial Robotics Could Improve the Inventory and Shipping Crisis of 2021

Supply chains have been disrupting virtually every industry from top to bottom. Numerous factors are contributing to the issue, so finding a solution that can mitigate the strain on the supply chain is challenging.

Robot-Ready Conveying Optimizes Pick-and-Place

From a machine builder's point of view, robots can solve many processing and packaging line problems, but the chosen material handling systems supplying the line can reduce the robot's performance.

Here's How Automated Packaging Gives Your E-commerce Business a Competitive Edge

Automated packaging solutions can streamline almost any business's operations, providing a potential competitive edge and benefits like reduced waste or lower labor needs.

Variance and Volume Advantageously Combined One of a Kind in Series

Up until now, users in the metal and plastics processing industries often faced a difficult choice: with CNC lathes and milling machines, one opted either for the largest possible variance or for large volumes, i.e., high quantities.

Leveraging Advanced 3d Measurement for Packaging & Logistics Applications

Generating accurate height data of boxes relative to the conveyor system is challenging to achieve with a single measurement tool. More often than not, this requires additional system configuration and potentially scripting.

How-To Guide on Mastering PACK EXPO Connects

With so many activities and over 2,600 scheduled demos taking place at PACK EXPO Connects, here is every preparation tool attendees need to ensure a successful event.

How Robotics Are Being Used in the Packaging Industry

If the packaging sector hadn't been an early adopter of automation, it would have struggled through the pandemic. That's not to say that the situation has been easy, but it could've been much worse without robotics.

Staying Competitive with Automation

Automation is making conveyors a more integral component because of the contributions they're making to the overall efficiency and productivity of today's processing and packaging lines.

Covid-19 Impact on Food Automation and Robotics Market

The current trend of automation has witnessed the development of new technologies that are capable of providing end-to-end automation for the production of certain processed foods.

Records 1 to 15 of 36

Featured Product

IP Seals for Robots

Freudenberg Sealing Technologies' IPRS (Ingress Protection Seals for Robots) provides reliable protection for robotic systems operating in harsh environments. Designed to prevent dust, moisture, chemicals, and wear from compromising performance, IPRS extends service life and reduces maintenance. The adaptive Z-shaped geometry ensures sealing integrity under continuous motion, making it ideal for high-speed automation and outdoor applications. Manufactured with high-performance elastomers such as Fluoroprene XP and EPDM, IPRS offers exceptional resistance to lubricants, cleaning agents, and extreme temperatures. This makes it the perfect solution for six-axis robots, SCARA robots, AMRs, AGVs, and cobots.

With its low-friction design and durable materials, IPRS enhances energy efficiency and operational reliability in industrial and autonomous robotics. Learn more about our IPRS Seals

Robotics and Automation - Featured Company

IDS Imaging Development Systems Inc.

World-class image processing and industrial cameras "Made in Germany". Machine vision systems from IDS are powerful and easy to use. IDS is a leading provider of area scan cameras with USB and GigE interfaces, 3D industrial cameras and industrial cameras with artificial intelligence. Industrial monitoring cameras with streaming and event recording complete the portfolio. One of IDS's key strengths is customized solutions. An experienced project team of hardware and software developers makes almost anything technically possible to meet individual specifications - from custom design and PCB electronics to specific connector configurations. Whether in an industrial or non-industrial setting: IDS cameras and sensors assist companies worldwide in optimizing processes, ensuring quality, driving research, conserving raw materials, and serving people. They provide reliability, efficiency and flexibility for your application.

.jpg)