An HMI could be used to replace physical inputs (such as buttons or switches) with virtual buttons on a user interface (UI). This can offer greater functionality and flexibility than a fixed control panel.

Understanding Human-machine Interfaces (HMIS)

Understanding Human-machine Interfaces (HMIS)

Article from | CIMON Inc.

PLCs are arguably the backbone of modern industry, as they allow complex tasks to be performed consistently and automatically. But even with PLCs, most automation systems require human interaction at some level. In this article we will look at one of the main tools used for this purpose: the human-machine interface, or HMI.

The exact definition of HMI is quite broad, and can technically be applied to any device that lets a human control a machine. However, the term most frequently refers to a display screen (either with touch functionality or physical buttons) used in an industrial automation system.

While PLCs perform most of the logic and low-level device communication, an HMI lets operators monitor device status and input commands. For example, a PLC might be programmed to act differently depending on a set of inputs. An HMI could be used to replace physical inputs (such as buttons or switches) with virtual buttons on a user interface (UI). This can offer greater functionality and flexibility than a fixed control panel.

HMI interfaces also support multiple pages that link to each other, graphs for displaying instantaneous and historical values, and other visualizations to help operators with production. An HMI can read and control practically any piece of data used by a PLC. HMIs have many additional features, but these vary by manufacturer.

What are HMIs used for?

Thanks to their versatility, HMIs can improve nearly any system that uses a PLC. Most factory floors, smart farms, water treatment facilities, and other industrial settings utilize one or more HMIs. In some cases, an HMI serves as a monitoring and troubleshooting tool, passively providing warnings and other low-level details. In other cases, the entire system is designed to have operators constantly interacting with HMIs.

At a remote pump station, for example, pumps are meant to operate continuously without human intervention. An HMI at such a site will only be used during maintenance, or when an engineer is fixing a known problem. On an assembly line, however, an HMI might be used to continuously control a robotic arm or other machine types. Because an operator is always expected to be present, the HMI’s ability to convey warnings and other information in real-time is much more consequential.

The exact function served by an HMI depends heavily on the setting in which it is used, as well as the target user. An interface designed specifically for engineers may look very different from one built for day-to-day workers or site managers. Fortunately, HMIs are re-programmable, and thus can fulfill a wide range of requirements without changes to the hardware.

Which HMI is right for me?

HMIs can range anywhere from small LCD screens with built-in buttons to powerful touchscreen computers with high-definition displays. In addition to HMIs, some companies sell Industrial PCs (IPCs), which offer increased processing power and general-purpose operating systems. But as computer processors become smaller and cheaper to produce, the line between HMIs and IPCs is fading. Given the multitude of options, how can you know which HMI is right for you?

A few factors worth examining are price, performance, size, and software capability. There is always a tradeoff between cost and quality. However, not every project needs the largest or fastest HMI; sometimes simplicity is actually preferable. A good rule of thumb is to identify an acceptable range for each factor, leave room for expansion, and then look for the most affordable option which meets all requirements. For example, an HMI might handle a preliminary test without issue, but if enough tags and other features are added during development, the performance could be affected. Similarly, an HMI model might fit perfectly in a panel cutout, but if a tool port is blocked by the setup, you would not be able to update the project from the field. Because of situations like these, giving yourself a bit of flexibility while planning can prevent huge problems later on.

Communication options are another important consideration, as not every HMI can directly interface with every hardware device. Though intermediary protocols (such as Modbus) are usually available, the resulting connection may be slow or inconvenient to program. Thus, it is a good idea to choose all of the project’s hardware at the same time to ensure compatibility. For more streamlined customer support and reduced engineering time, it is helpful to use the same brand for both PLCs and HMIs. In some situations, you can even combine the two into a single hardware unit. Some companies—including CIMON—sell Hybrid units that merge a touchscreen HMI and PLC into one device. For more general projects, CIMON also offers a range of standalone HMIs, all featuring advanced communication protocols and competitive pricing.

HMI Software

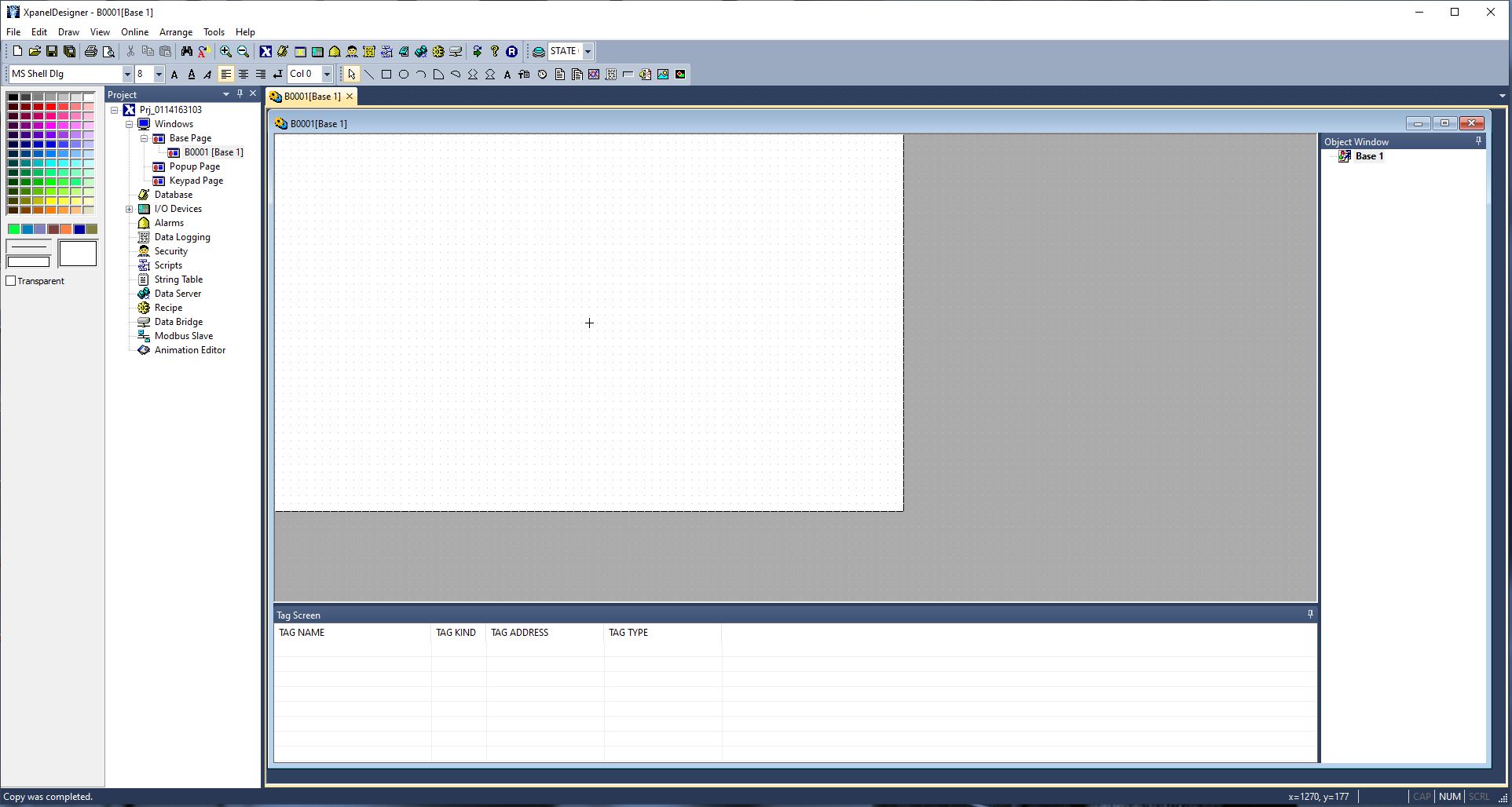

Regardless of which option you choose, an HMI is only as good as its software. While touchscreen applications could be programmed from scratch (at least in theory), most manufacturers offer project-editing software for their HMIs. One example is XpanelDesigner, which is used for CIMON Xpanel HMIs. From this program, users can design graphical pages, define custom user actions, insert visualization objects, and configure inter-device communication. Projects can then be downloaded to an Xpanel HMI using one of several connection options. XpanelDesigner also provides a scheduling system, scripting engine, HMI simulator, and other convenient features.

Though UI appearance varies from project to project, designers tend to follow a few common principles. Because industrial workers need to access information as quickly as possible, text and other UI elements should be large and clearly visible. Often, high-contrast colors are preferred over aesthetically pleasing ones. For example, a “STOP” button will typically be bright red—both so that operators do not press the button by accident, and so that the button can be easily found when necessary. Each function should be clearly distinguishable from the others.

Page layout also has a large impact on user experience. In theory, you could place every button and piece of data on the same screen, but this would be overwhelming and difficult to navigate. Instead, designers should seek a balance between the organization, responsiveness, and accessibility. One way to facilitate this would be to include the main menu screen. From this menu, users should be able to find any other page or feature using visual cues and descriptions alone.

Furthermore, UI features should be designed with specific use cases in mind. As an example, if the operator is viewing a screen that displays a machine’s status, then error codes could be programmed to pop up automatically and give a short description. This would prevent the operator from needing to go to a different screen, thus saving time and effort.

In addition to interfacing humans and machines, HMIs can be used as a bridge between devices. While most time-sensitive logic should be performed by a PLC, certain kinds of communication are better left to an HMI. Using scripts or other built-in functions, an HMI can manipulate certain kinds of values much more efficiently than a PLC. Log creation, data processing, and trend analysis are all excellent examples of HMI applications.

How to Learn More

In summary, an HMI lets operators monitor and control devices from a user interface. Just as PLCs serve a wide variety of purposes, HMIs can be custom-tailored to different industries and use cases. As technology advances, HMIs become more cost-effective and gain new capabilities. If you would like to learn more about HMIs, including technical specifications and product comparisons, please visit our HMI and IPC product pages. You can also download XpanelDesigner for free by clicking here and creating an account. CIMON’s technical support is always free, so do not hesitate to reach out to support@cimoninc.com with any questions or comments.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product