3D printed objects can include intricate machine components, through to edible items, and as a result, the additive material could range from powdered metals to chocolate. Whatever the material and shape required, functionally, the 3D printing technique is the same.

What are the motion control requirements for additive manufacturing machines?

What are the motion control requirements for additive manufacturing machines?

Ed Novak, General Manager | Trio USA

When developing a 3D printing machine for additive manufacturing, accurate and coordinated motion control is essential.

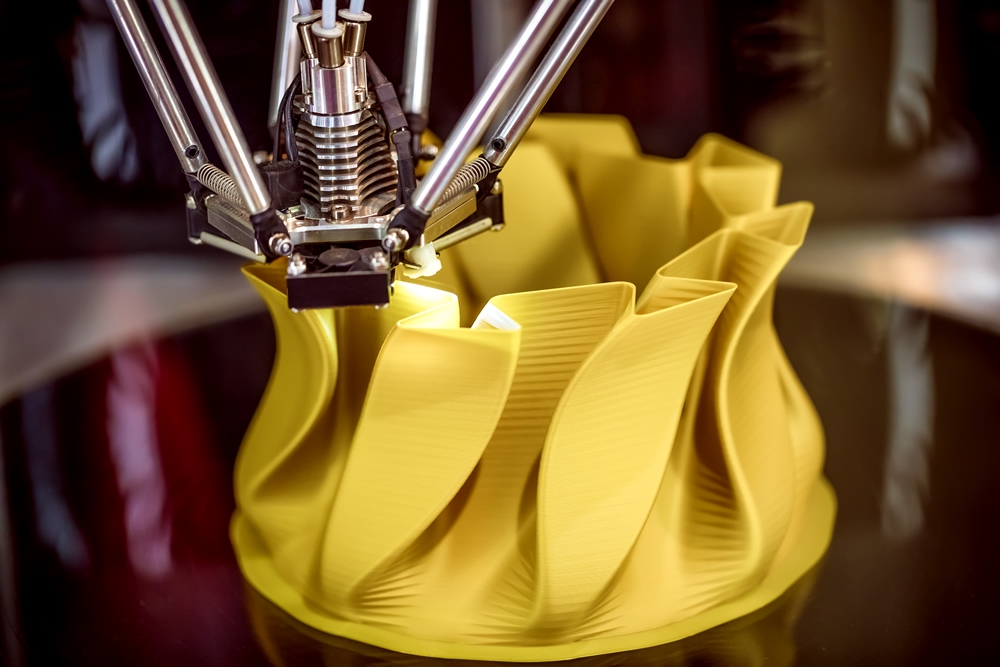

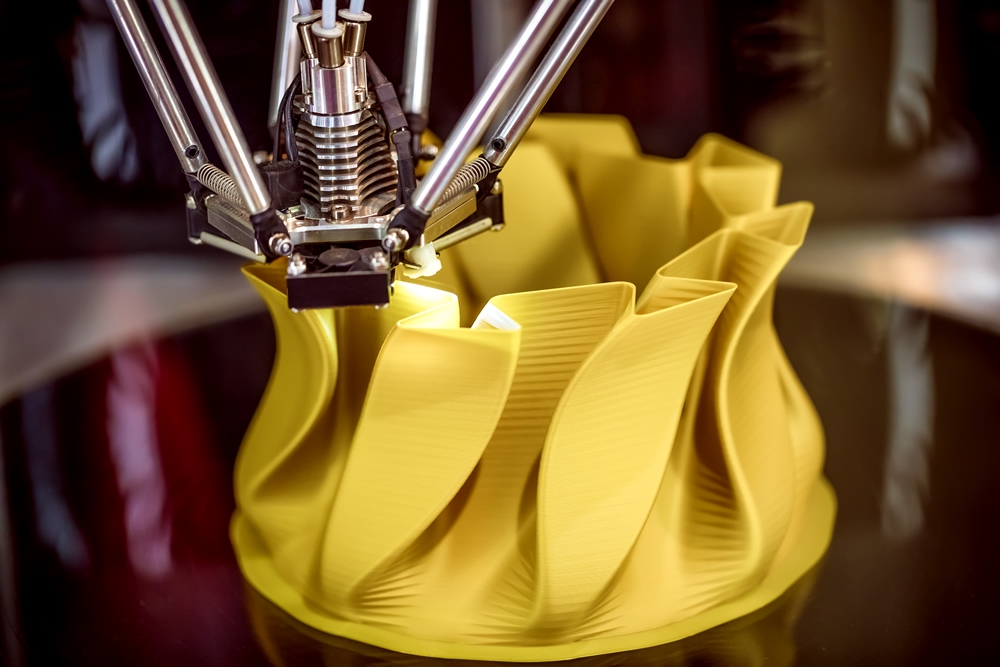

The most common type of additive manufacturing, also known as 3D printing, is fused filament fabrication. The construction material is melted into a malleable state and is then extruded through a nozzle. This extrusion, or ‘printing’, takes place in a pre-set pattern, with each layer built up in three dimensions to form an object.

3D printed objects can include intricate machine components, through to edible items, and as a result, the additive material could range from powdered metals to chocolate. Whatever the material and shape required, functionally, the 3D printing technique is the same.

The advantage of 3D printing has traditionally been for fast, low-cost prototype production. 3D printing enables manufacture without the need for tooling development, and the technique also allows much faster changes to update designs.

However, 3D printing is also beginning to be used in serial production – especially where traditional techniques might not be as effective. For example, if you’re making a unique component that’s too intricate to be machined, a 3D printer could potentially do the job.

Motion control requirements for 3D printing

To print in three dimensions, the printing machine requires movement of its nozzles across coordinates plotted to X and Y axes, that correspond to side-to-side, lateral motion, as well as a Z axis that represents up and down, vertical motion.

Each of the three axes needs a motor to generate rotational movement that converts into linear motion. Crucially, to achieve 3D motion control, individual axes must be coordinated by a controller. For this reason, the motion controller – also known as a motion coordinator – is the brain of any additive manufacturing system.

The top priority is that motion must be extremely smooth and controlled to achieve the required quality of finish. This means seamless communication between the controller, drives and motors, involving sub-millisecond position loop update rates, as well as minimal lag and jitter.

A motion controller must also execute a G-code file, which is among the most common computer-aided manufacturing languages. 3D printers have a slicer program that cuts the image design into layers. These layers are then output to G-code format that is executed by the motion controller and converted into X, Y and Z axis movements.

Another key requirement of the motion controller is integration of a temperature control device, such as a thermocouple I/O module. The printing area must be maintained at a specific temperature for the material to bond correctly, and also to maintain the right level of print material viscosity in order to achieve a repeatable quality of print. This rate will change depending on the material, so a control loop must be used to maintain the optimum temperature.

The motion controller must also be flexible to allow quick and easy changes to the program to print new or modified designs. This flexibility also means the ability to integrate different types of motors. This is important as a 3D printer could include servo motors controlling the axes, as well as a stepper motor controlling the in feed, all within the same system.

For industrial use, especially if a 3D printer is in daily or constant operation, rugged build quality is important as well. The robust features of an industrial motion controller include insulated I/O points, optical coupling, and 24V I/O. These aspects help ensure durability, meaning less downtime, crucial to optimise productivity. These features will also increase machine longevity, lowering the total cost of ownership.

PLC or motion controller for a 3D printer?

Instead of a motion controller, some 3D printer manufacturers use programmable logic controllers (PLCs). PLCs are used around the world in all types of automated control applications, so it’s easy to find engineers that know how to program them. As the main PLCs are manufactured by global companies, it’s straightforward to purchase parts.

However, it’s generally more difficult to achieve the required motion performance from a PLC compared to a dedicated motion controller. This is because PLCs, combined with their IEC programming languages, are primarily designed for logic control. By comparison, hardware dedicated to optimising motion control, combined with an application development environment designed for the same purpose, makes the kind of programming required for a 3D printer much faster and easier to achieve.

A motion controller typically includes a programming language dedicated to the task, involving a reduced volume of commands that are more specific to motion functions, making development simpler and faster. Real text, English language commands can also be used, meaning that it’s possible to program a motion controller with very little training. However, most modern motion controllers are still IEC language compatible, should engineers wish to program in their preferred language choice.

In addition, a significant drawback of using a PLC in many 3D printer applications is cost. PLC technology is typically more expensive, because it includes broad features designed to provide flexible control across a wide variety of applications. For a 3D printer, which is based largely around motion control requirements, you’re paying for PLC functionality you’re probably not going to use.

Flexible application development

Some large 3D printer manufacturers build their own controller to meet specific requirements, where large volume control board manufacture can drive down the cost of production. Even for large 3D printer OEMs, the advantage of partnering with a motion specialist enables the involvement of dedicated knowledge to optimise control performance. This approach also provides expertise at the cutting edge of the latest motion technology to ensure keeping up to date with the latest developments. Freeing up internal resource by partnering with a motion specialist can also reduce development cost – dependent on production volume – and crucially, it can achieve a faster time to market for the overall machine.

When selecting a motion control partner, it’s important that they can customise an application to precisely suit the 3D printing requirements. A flexible approach to design should also include future support for both the hardware and the programming environment. For these reasons, working with an agile motion development partner can be crucial for a 3D printing machine OEM, whatever their scale of manufacture.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product