Compared to alternative solutions, such as multiple robots or overhead gantry systems, StackTrax can provide a space and cost-saving alternative that will improve cycle time and overall throughput.

StackTrax - The Industry's First Off-The-Shelf Dual Axis RTU

StackTrax - The Industry's First Off-The-Shelf Dual Axis RTU

Product Q&A with IPR Robotics | IPR Robotics

Tell us about your product and what you feel sets it apart from similar products.

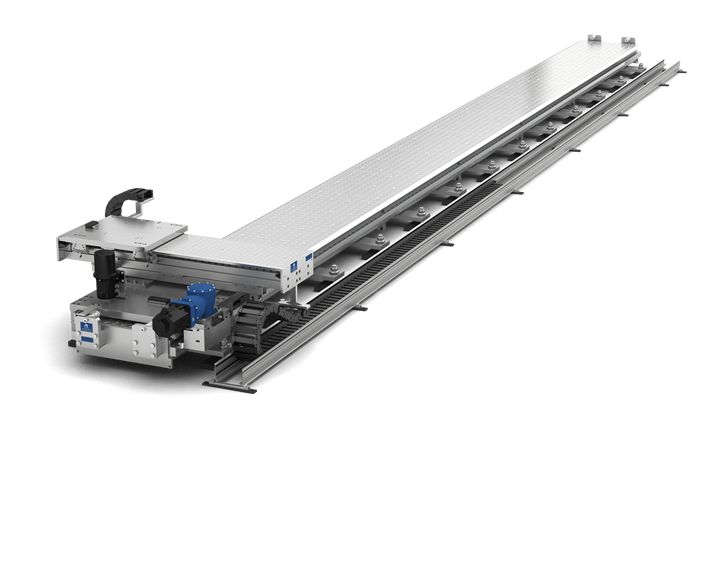

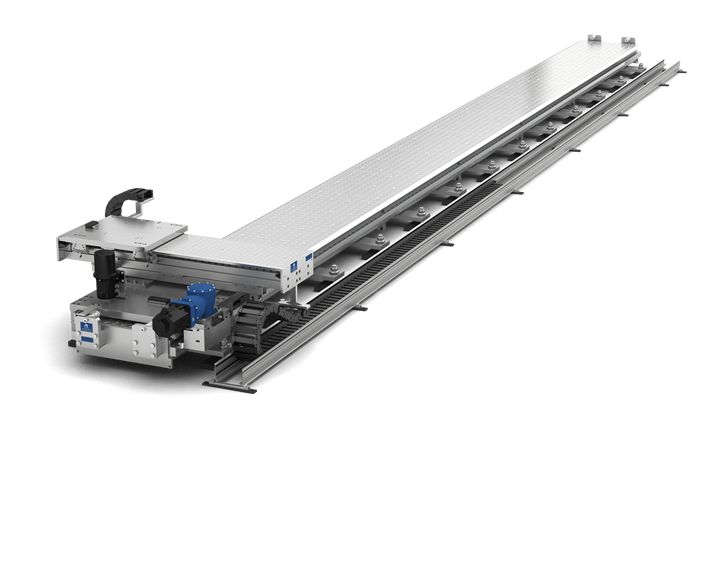

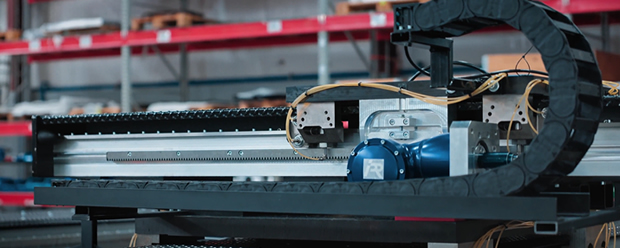

StackTrax is the industry’s first off-the-shelf dual axis RTU, designed around the needs of CNC, Material Removal, and other Machine Tending applications. Compared to alternative solutions, such as multiple robots or overhead gantry systems, StackTrax can provide a space and cost-saving alternative that will improve cycle time and overall throughput. Additionally, it is modular to handle different sizes of robots, providing a mix of flexibility and standardization to adapt to many different automation requirements. It can also be configured to be used without a robot. Like a human that needs to take a step or lean to reach an item, StackTrax gives that extra reach or dexterity to robots, allowing them to do more!

StackTrax is the industry’s first off-the-shelf dual axis RTU, designed around the needs of CNC, Material Removal, and other Machine Tending applications. Compared to alternative solutions, such as multiple robots or overhead gantry systems, StackTrax can provide a space and cost-saving alternative that will improve cycle time and overall throughput. Additionally, it is modular to handle different sizes of robots, providing a mix of flexibility and standardization to adapt to many different automation requirements. It can also be configured to be used without a robot. Like a human that needs to take a step or lean to reach an item, StackTrax gives that extra reach or dexterity to robots, allowing them to do more!

Tell us about the R&D behind this product. Who is this product designed for? What problem is it solving?

At its core, StackTrax was created to fill a niche left unserved by other gantry systems from real customer input. The customer approached us with a set of concerns in which their environment had cost, complexity, and space constraints that made overhead gantry systems and H-gantries infeasible. Our team of skilled engineers were able to work with the customer and create a solution for the problem that offers high flexibility, lower setup cost and complexity than most traditional gantry systems. Because it’s built from IPR’s standard rails, lead times are just as short as they are for any other IPR equipment. As an overall simpler system that offers the robot better access to machines than other gantries, it also simplifies motion planning and programming, allowing you to get maximum efficiency from your robots. At IPR Robotics, we are committed to thinking outside the box and problem solving in unique ways to ensure there is an effective solution to our customers' problems.

Give us an idea on the installation process.

Installing StackTrax is as simple as connecting the pieces of the bottom rail, leveling it, and then securing it to the floor. When creating StackTrax, we made sure to keep ease of installation in mind by making installation almost identical to our other 7th Axis RTU’s. We do provide a walk-through manual that explains the proper way to install and set up. If installation or assistance on our end is required, we have a team who can go on-site and help with the initial installation.

How is your company set up to support the users of your products.

Customer satisfaction is our main priority when it comes to product installation, use, and maintenance.

Need onsite support?

We have options to send our skilled engineers onsite to help trouble shoot any obstacles.

Not sure if onsite support is needed just yet?

Our design engineers are always available via email and able to schedule one-on-one phone calls to help troubleshoot any obstacles.

With any sale, we make sure our customers are set up for success with documentation that includes maintenance recommendations, installation tips, and contact information.

What feedback have you received from the field? Can you share a use case and the results?

With the first installations completed, we have heard first-hand how StackTrax has helped save time with the integrators’ programming compared to alternative solutions. StackTrax was able to increase the customers’ throughput by 41% at a big six medical device manufacturer. In addition, the customer informed us that StackTrax was able to integrate with their pre-existing robotic production software seamlessly with the unattended runtime increase is over 45% with a 62% downtime reduction. IPR was able to solve their challenges that were initially presented through creative thinking and meticulous planning to ensure their needs were met for their space.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product