With the artificial kangaroo, Festo also shows how pneumatic and electric drive technology are combined in a highly dynamic system.

Contributed by

Recovering, storing and releasing energy based on a natural model

On Australia’s coat of arms it stands for progress, whilst the special way it moves is unique in the animal world: the kangaroo. With the help of its unusually long back legs, the marsupial is able to move quickly and efficiently over terrain.

Its jumping mechanism enables the kangaroo to increase its speed without using more energy in doing so. With every bounce it can store energy from the landing phase and use it again for the next jump. The Achilles tendon assumes an important function here, which is why it is particularly pronounced on the natural kangaroo.

New prospects due to bionics

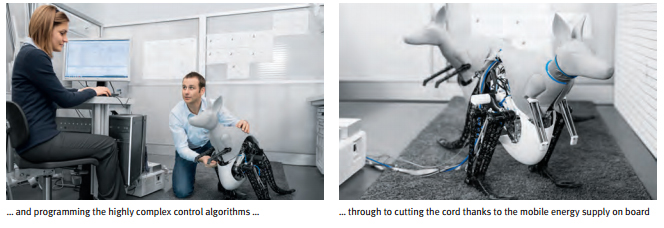

A development team from Festo’s Bionic Learning Network spent two years recreating the jumping behaviour of the natural kangaroo as closely as possible and learning from it.

As an innovation leader for automation technology, Festo is always on the lookout for new or not yet widespread movement patterns and drive concepts. One source for new knowledge and future technologies here is nature.

Technical implementation of the unique movement pattern

Like its natural model, the BionicKangaroo can recover, store and retrieve the energy efficiently on the next jump. The technical implementation requires both sophisticated control technology and stable jump kinematics.

The consistent lightweight construction and the intelligent combination of pneumatic and electric drives enable the unique jumping behaviour. The system is controlled by gestures.

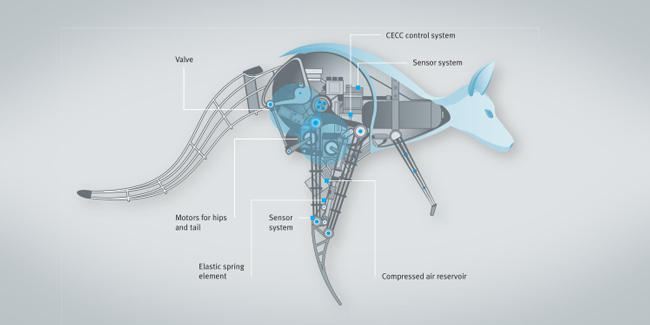

Mobile energy supply on board

Festo paid particular attention to the mobile energy supply on the artificial kangaroo and even developed two different concepts for this purpose. Either a small compressor or a high-pressure storage device can be placed inside the body. Both supply the compressed air necessary when jumping, which is dosed out exactly by two Festo MHE2 solenoid valves. Lithium polymer rechargeable batteries act as electrical energy storage devices. They supply both the valves and the electric drives, as well as the integrated Festo CECC control system, with the necessary power.

Highly complex overall system: clever combination of drives, control technology and the mobile energy supply

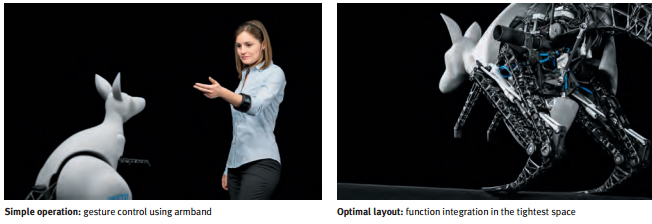

Intuitive operating concept using a gesture control system

The BionicKangaroo can be controlled by gestures using a special armband. The armband detects the operator’s muscular movements. A position sensor in the armband records the movement of the arm. The armband sends these signals via Bluetooth to the artificial kangaroo’s compact control system, upon which it starts to interact with its operator.

Electrical drives for precise movements

When standing, the kangaroo touches the floor with both feet and its tail, thus giving it a stable three-point contact. Its tail also provides the necessary balance when jumping. An electric servomotor specifically controls its angle of attack and ensures the corresponding compensatory movement. The kangaroo thereby compensates for the countermovement of its legs, which have to be brought forward for the landing phase. The legs are also controlled by two electric servomotors, which sit between the hip and thigh, so that these can be moved forward and backwards. All the control signals here are generated by the compact control system.

Pneumatic actuators for dynamic jumping behaviour

A Festo DSNUP 20 pneumatic lightweight cylinder is attached along each lower leg, which actuates the leg. The knee and ankle joint are connected via a so-called positive kinematic device, resulting in an interlinked movement sequence.

The function of the natural Achilles tendon is adopted by an elastic spring element made of rubber. It is fastened at the back of the foot and parallel to the pneumatic cylinder on the knee joint. The artificial tendon cushions the jump, simultaneously absorbs the kinetic energy and releases it for the next jump.

Integrated controls and real-time diagnostics

The condition monitoring as well as the precise control technology ensure the required stability when jumping and landing. The energy status of the kangaroo, the manipulated variables and angle of attack are constantly monitored and evaluated. At the same time, the control system processes multiple sensor values. They go into complex control algorithms, which result in the manipulated variables for triggering the cylinders and motors.

In order to move as little mass as possible, all the components are optimally laid out, networked and controlled in the smallest possible space. The housing elements are cut out of foam. The kinematic system is made out of laser-sintered parts reinforced with carbon. As a result, the artificial animal weighs just seven kilograms with a height of around one metre, and it can jump up to 40 centimetres high and up to a distance of 80 centimetres.

Unique jumping behaviour: intelligent combination of installed components for stable and efficient jumping

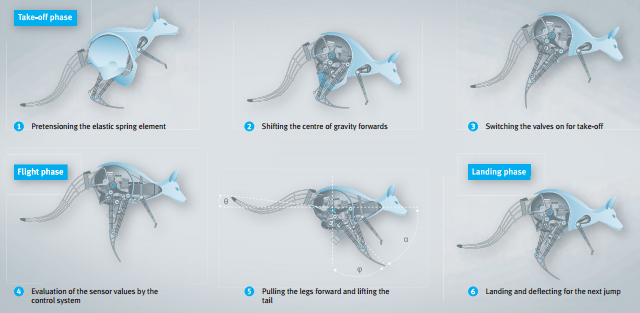

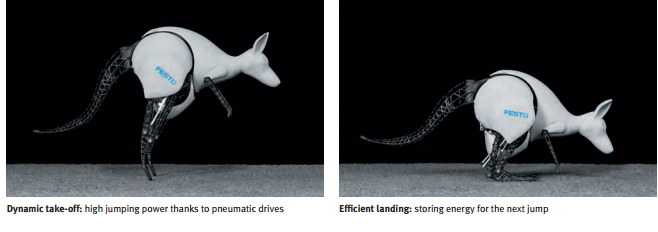

The take-off and flight phase

Before the first jump, the elastic tendon is pneumatically pretensioned. The BionicKangaroo shifts its centre of gravity forwards and starts to tilt. As soon as a defined angle is reached at a corresponding angular velocity, the pneumatic cylinders are activated, the energy from the tendon is released and the kangaroo takes off.

In order to jump as far as possible, the kangaroo pulls its legs forward during the flight phase. This creates torque at the hip, for which the artificial animal compensates with a movement of its tail. The top of the body thereby stays almost horizontal.

The landing phase: energy for the next jump

Upon landing, the tendon is tensioned again, thus converting the kinetic energy of the previous jump to potential energy. The energy is thereby stored in the system and can be called on for the second jump. The landing phase is the critical process for recovering the energy and is responsible for the kangaroo’s efficient jumping behaviour. During this phase the tail moves towards the ground and thus back to its starting position.

Reduced energy consumption in the following jumps

If the kangaroo continues jumping, it channels the stored energy directly into the next jump. The potential energy from the elastic tendon is used again at this point. The valves switch at the right moment and the next jump begins. In this way it takes several jumps one after the other.

If the BionicKangaroo is supposed to come to a standstill, it must absorb as much energy as possible. To do so, the pneumatic actuators are switched accordingly and the tendon is actively tensioned again.

Holistic approach: The team spent two years on the technical implementation – from the right choice of materials …

Stimulus for production of the future

Besides the technical implementation of the unique jumping kinematics, the BionicKangaroo demonstrates several aspects of integrated automation at once: The system brings its components together in the smallest space. The many functions are coordinated using a highly complex control technology system. For Festo, the principle of permanent diagnostics is a guarantee of operational safety and process stability – whether on bionic objects or in an everyday industrial environment.

Other interesting approaches for the automation technology of the future are the concept of recovering, storing and efficiently reusing potential energy as well as the energy supply system thanks to mobile pneumatics.

Energy recovery in the automation sector

In industrial automation, knowledge about energy recovery and storage plays an important role – for instance when it comes to recovering heat on compressors or feeding electrical energy back into the mains.

Intelligent combination of pneumatics and electrics

With the artificial kangaroo, Festo also shows how pneumatic and electric drive technology are combined in a highly dynamic system.

The kangaroo achieves its high jumping power with the aid of pneumatics. Pneumatic actuators are generally powerful and highly dynamic. They are comparatively light and pliable, which means they also act as shock absorbers for the kangaroo on landing. In the places where the highest positioning accuracy is called for, electric motors are used – for example, when it comes to controlling the tail and hip.

Efficient solutions from the right selection

In everyday industrial situations too, the respective application decides whether the best solution is based on pneumatic or electrical drives or both.

As a specialist in both technologies, Festo offers its customers tailored solutions and supports them with a comprehensive service and the appropriate simulation tools.

Technical data

- Size: 100 cm upright

- Sitting height: 60 cm

- Weight: 7 kg

- Jump distance: up to 80 cm

- Jump height: up to 40 cm

- 1 Festo CECC control system with interfaces for Ethernet, CAN, RS232, RS485, digital IOs and IO link

- 3 Harmonic drive motors

- 2 Festo DSNUP 20 standard cylinders

- 2 Festo MHE2-MS1H-5/2-M7 quick-acting valves

- 1 XSENS Attitude Heading Reference System (AHRS) •

- 1 Festo SPTE-P10R-Q4-V-2.5K pressure transmitter

- 1 Metallux Hall rotary potentiometer

- Supply pressure: 8 bar

- Body shell: foam

- Kinematics: laser-sintered parts with carbon reinforcement

- Operating concept: gesture controls using Myo armband by Thalmic Labs Inc. with EMG muscle activity sensors and integrated position sensor

- Range: 50 m Bluetooth

Project participants

Project initiator: Dr Wilfried Stoll, managing partner, Festo Holding GmbH

Project management: Dr Heinrich Frontzek, Elias Knubben, Festo AG & Co. KG

Project team: Johannes Stoll, Nadine Kärcher, Daniel Bauer, Daniel Strohhäcker, Xander Gerrmann, Merlin Morlock, Mart Moerdijk, Teresa Martin, Festo AG & Co. KG

Control technology: Dr Alexander Hildebrandt, Martin Ehrle, Marius Müller, Festo AG & Co. KG; Professor Knut Graichen, Sebastian Hentzelt, Ulm University, Institute for measurement, control and microtechnology

Scientific support: Dr Nina Gaißert, Festo AG & Co. KG

About Festo

Festo is a leading manufacturer of pneumatic and electromechanical systems, components, and controls for process and industrial automation. For more than 40 years, Festo Corporation has continuously elevated the state of manufacturing with innovations and optimized motion control solutions that deliver higher performing, more profitable automated manufacturing and processing equipment.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product