Sony backs Acutronic Robotics' hardware robot operating system

Darrell Etherington for TechCrunch: Sony is investing in Acutronic Robotics‘ Series A round, via its Sony Innovation Fund. Sony will also adopt Acutronic’s Hardware Robot Operating System (H-ROS), for use in its own robotics division, the company says. This funding follows investment by DARPA in Acutronic’s platform, which aims to become an industry standard for robotics components from across hardware and software providers.

Darrell Etherington for TechCrunch: Sony is investing in Acutronic Robotics‘ Series A round, via its Sony Innovation Fund. Sony will also adopt Acutronic’s Hardware Robot Operating System (H-ROS), for use in its own robotics division, the company says. This funding follows investment by DARPA in Acutronic’s platform, which aims to become an industry standard for robotics components from across hardware and software providers.

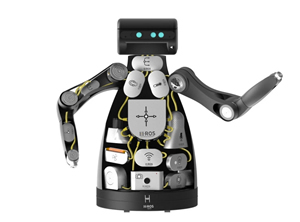

Acutronic was set up in 2016, and offers a way to allow components combine in new robotics systems easily with ready-made compliance with industry and commercial standards for easy deployment. The idea is to take out some of the more complicated base level steps towards deploying robotics in industry and the workplace, with a focus on building robots that are both reusable across applications and reconfigurable to suit different purposes.

The size of the Sony investment, or Acutronic’s Series A round was not disclosed. But Sony’s strategic use of the platform in its own operations, and DARPA’s prior investment, suggest there’s a lot of interest in this solution for unifying a fractured robotics landscape. Full Article:

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product