MassRobotics Startups Surpass $1B in Funding

This remarkable achievement underscores the vital role MassRobotics plays in accelerating robotics innovation, commercialization, and adoption of advanced technologies.

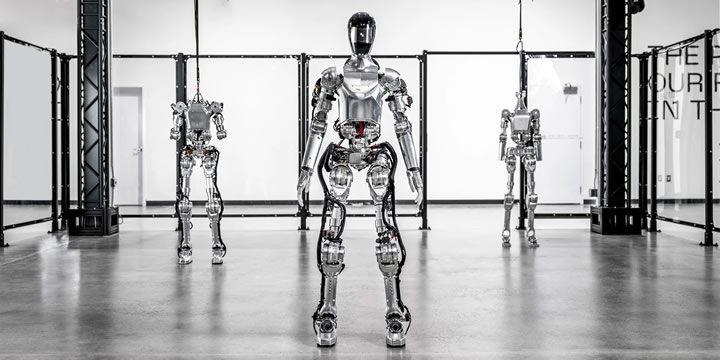

Figure Raises $675M at $2.6B Valuation and Signs Collaboration Agreement with OpenAI

Investments from Microsoft, OpenAI Startup Fund, NVIDIA, Jeff Bezos (through Bezos Expeditions), Parkway Venture Capital, Intel Capital and others

Figure and OpenAI are collaborating to develop next generation AI models for humanoid robots.

UBTECH Robotics Announces Largest Artificial Intelligence Funding in History

$820 Million in Series C Investment Values Company at $5 Billion, Catapulting UBTECH to Worlds Most Valuable Consumer Robotics Company

Sony backs Acutronic Robotics' hardware robot operating system

Darrell Etherington for TechCrunch: Acutronic was set up in 2016, and offers a way to allow components combine in new robotics systems easily with ready-made compliance with industry and commercial standards for easy deployment.

Chrysalix partners with Dutch RoboValley on €100 million robotics fund

Terry Dawes for Cantech Letter: Vancouver-based Chrysalix Venture Capital has announced a €100 million fund aimed at driving the global robotics revolution, in partnership withRoboValley, a centre for robotics commercialization based at the Delft University of Technology in the Netherlands.

The RoboValley Fund is Chrysalix’s first robotics fund, and will concentrate on disbursing seed and Series A rounds of funding to early-stage companies developing component technology, intelligent software, and other breakthrough robotics technologies.

“Robotics is predicted to be the next big step in the digital revolution having an unprecedented impact on the way that we live, and provides an answer to some of the grand challenges of the 21st Century,” said RoboValley managing director Arie van den Ende. “Together with Chrysalix long-standing expertise in commercializing early stage industrial innovations, the RoboValley Fund will bring much needed capital and accelerated paths to market for our most promising next generation robotics technologies.” Cont'd...

May Fundings, Acquisitions, IPOs and New Funds

May was another big month of money flowing into robotic ventures. But May was even bigger in launching new robotics-focused venture funding groups.

Records 1 to 6 of 6

Featured Product

Elmo Motion Control - The Platinum Line, a new era in servo control

Significantly enhanced servo performance, higher EtherCAT networking precision, richer servo operation capabilities, more feedback options, and certified smart Functional Safety. Elmo's industry-leading Platinum line of servo drives provides faster and more enhanced servo performance with wider bandwidth, higher resolutions, and advanced control for better results. Platinum drives offer precise EtherCAT networking, faster cycling, high synchronization, negligible jitters, and near-zero latency. They are fully synchronized to the servo loops and feature-rich feedback support, up to three feedbacks simultaneously (with two absolute encoders working simultaneously). The Platinum Line includes one of the world's smallest Functional Safety, and FSoE-certified servo drives with unique SIL capabilities.

Robotics and Automation - Featured Company

Encoder Products Company

At Encoder Products Company, we specialize in the encoders that provide you with motion feedback. EPC has been a leading designer and manufacturer of motion sensing devices for more than 50 years, we understand that each industrial automation application is different, and you need encoders that fit the needs of your applications. Our encoders are highly configurable, offer an array of shaft or bore sizes, output types, connector types, mounting options, and resolutions as high as 65,536 CPR.