igus Introduces Iggy Rob: An Affordable Humanoid Robot for Industrial and Service Applications

The motion plastics specialist igus has unveiled its first humanoid robot, Iggy Rob, designed to support industrial production, service environments, and transport tasks. The robot, offered at a market-disruptive price of approximately $54,500, presents a cost-effective entry point into humanoid robotics for companies seeking automation solutions.

The introduction of Iggy Rob arrives amid forecasts estimating that up to 20 million humanoid robots could be deployed in industrial applications by 2030. While traditional humanoid systems remain prohibitively expensive for many businesses, igus aims to lower the barrier to adoption with an affordable, versatile robot powered by its own motion plastic components.

“Because our environment is built by and for humans, the potential for humanoid robots is immense,” stated Jan Hennecke, Business Unit Manager for LCA/RBTX at igus. “Iggy Rob offers a practical, affordable way for companies to begin integrating robotics into their operations.”

The introduction of Iggy Rob marks the culmination of years of innovation at igus in the field of Low-Cost Automation. Building on extensive experience with its own motion plastics components, igus has progressively advanced toward the realization of a humanoid robot. Key developments include the launch of the igus ReBeL cobot in 2022, a low-cost robotic arm, the igus ReBeL Hand, a low-cost humanoid hand in 2023, and the igus ReBeL Move, an autonomous mobile platform, a low-cost AMR in 2024. Each of these milestones has contributed to demonstrating what can be achieved in the humanoid robotics space through the use of igus technology, culminating in the creation of an affordable, fully integrated humanoid system.

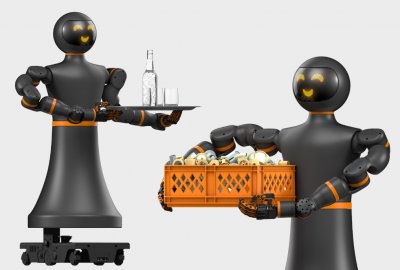

Standing approximately 1.70 meters (67 inches) tall, Iggy Rob can operate autonomously for up to eight hours on a single charge. It is equipped with two ReBeL Cobot arms, bionic hands, a LiDAR sensor, and 3D cameras for advanced object detection and navigation. These features enable smooth mobility and interaction in dynamic environments.

The robot is powered by igus Robot Control software (iRC), is CE-certified, and is approved for fleet management under VDE 5050 standards. Integration with the ROS2 interface ensures compatibility with modern robotics infrastructures.

Rather than using legs, Iggy Rob is built upon the proven ReBeL Move autonomous mobile robot (AMR) platform. This base features a robust three-point bearing and supports a load capacity of 50 kilograms (110 pounds) with a payload of 100 kilograms (220 pounds). This design choice aligns with the existing infrastructure of many factories and enhances stability and functionality.

igus has identified various potential use cases, including service tasks at reception desks, transport roles within facilities, and canteen operations such as clearing cutlery. Internally, igus intends to deploy Iggy Rob for component placement in injection-molding machines.

igus offers a “test before you invest” program to accelerate adoption and ensure suitability for diverse environments. This initiative allows companies to trial Iggy Rob on-site with support from igus experts who assess feasibility and performance in real-world applications. Should the trial prove successful, the robot can be purchased at a price significantly lower than comparable humanoid robots, which often cost two to three times more.

Further details and technical specifications are available at: https://www.igus.com

About igus®

igus GmbH develops and produces motion plastics. These self-lubricating, high-performance polymers improve technology and reduce costs wherever things move. In energy supplies, highly flexible cables, plain and linear bearings, and lead screw technology made of tribo-polymers, igus is the worldwide market leader. The family-run company based in Cologne, Germany, is represented in 35 countries and employs 4,600 people across the globe. In 2023, igus generated a turnover of €1.136 billion. Research in the industry's largest test laboratories constantly yields innovations and more user security. Two hundred 234,000 articles are available from stock, and service life can be calculated online. In recent years, the company has expanded by creating internal startups, for example, ball bearings, robot drives, 3D printing, the RBTX platform for Lean Robotics, and intelligent "smart plastics" for Industry 4.0. Among the most significant environmental investments are the "chainge" program – recycling used e-chains and participating in an enterprise that produces oil from plastic waste.

Featured Product